Method for manufacturing three-dimensional small-diameter vessel model

A vascular model and small-caliber technology, applied in the field of bioengineering, can solve the problems of high operation difficulty, complicated production steps, and many technological processes, and achieve the effect of good biocompatibility and strong mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

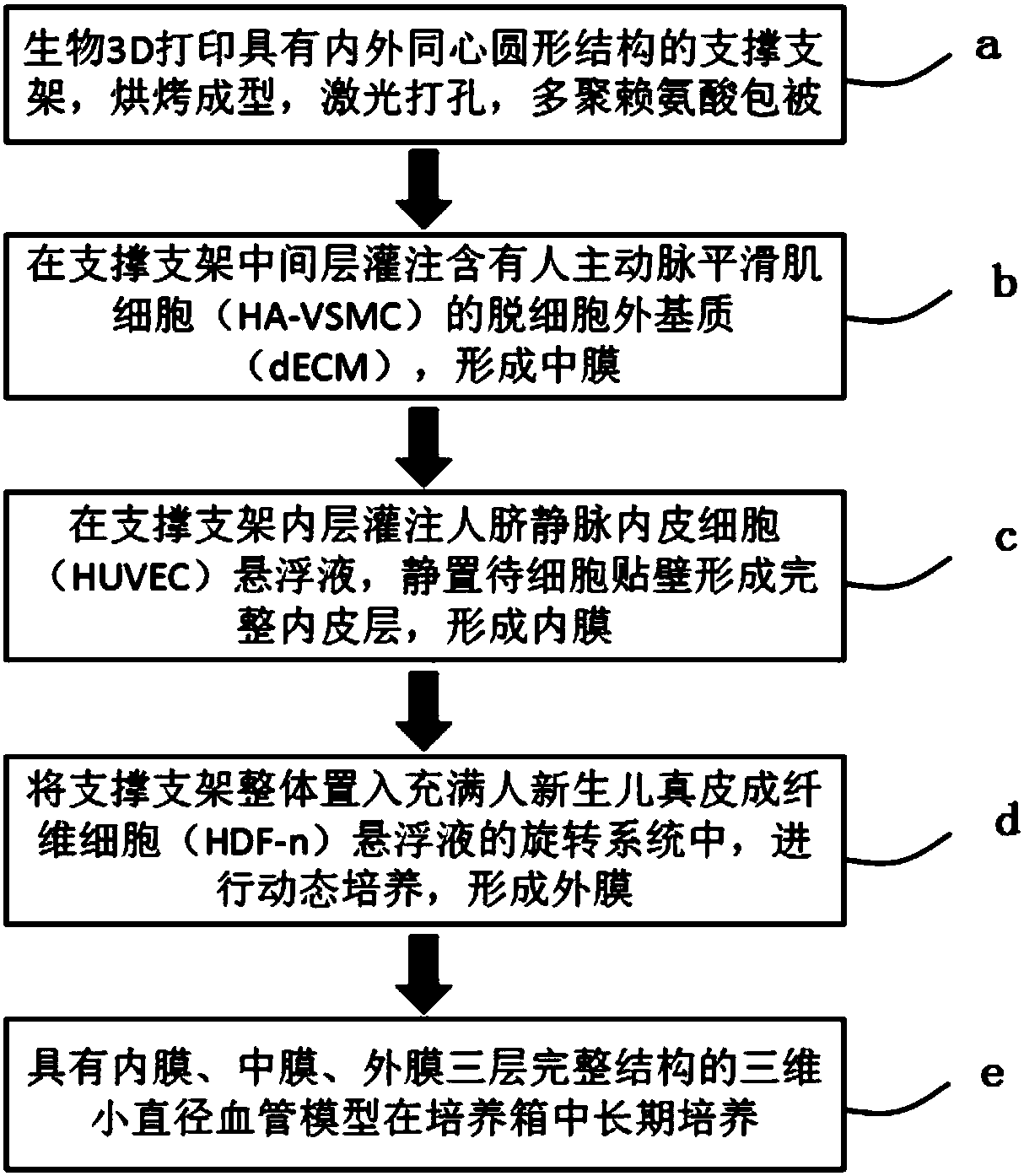

[0052] refer to Figure 1 to Figure 7 , in one embodiment, a method for making a three-dimensional small-diameter blood vessel model, comprising the following steps:

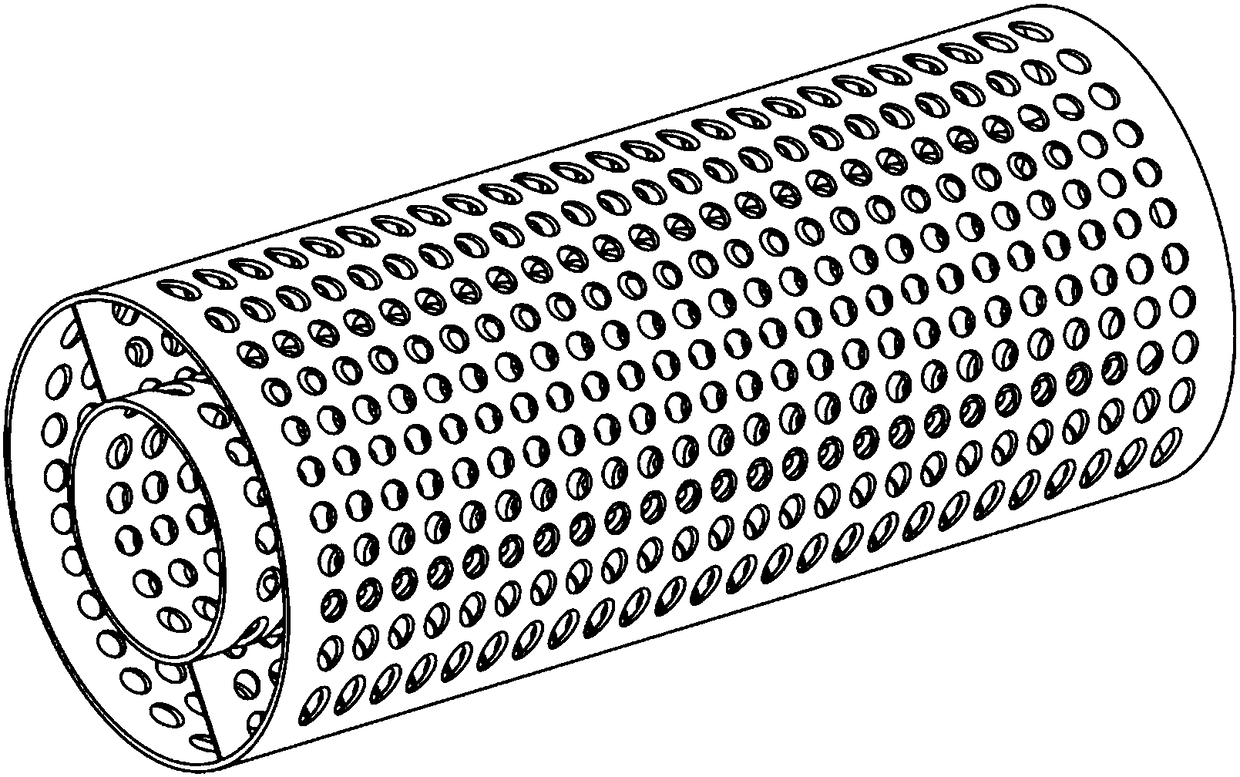

[0053] a. Preparation of support bracket: use silicone material to 3D print a support bracket with inner and outer concentric circular structures;

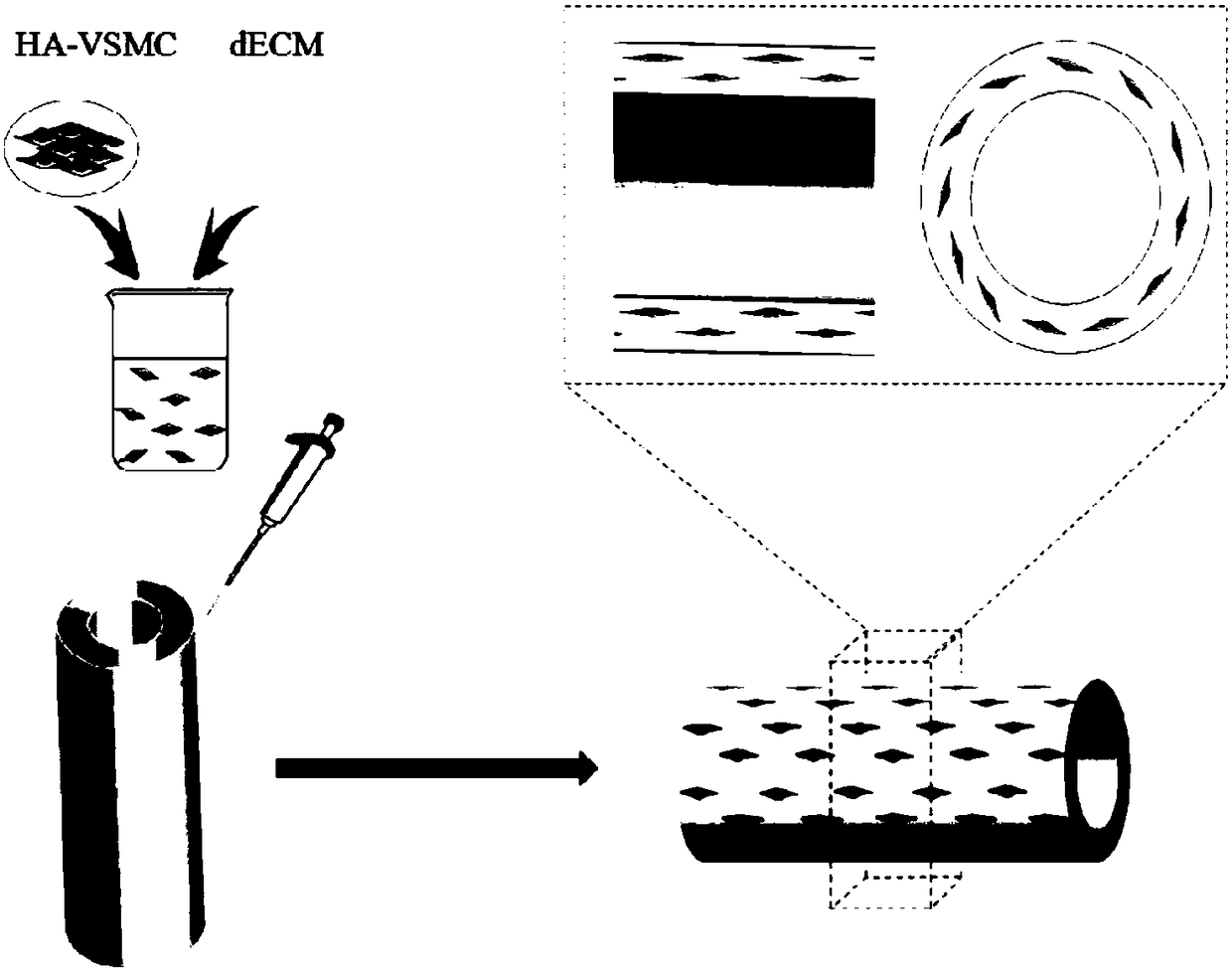

[0054] b. Formation of the media: perfusing the decellularized extracellular matrix containing human aortic smooth muscle cells in the middle layer of the support bracket to form the media;

[0055] c, intima formation: perfuse the human umbilical vein endothelial cell suspension in the inner layer of the support bracket to form the intima;

[0056] d. Adventitia formation: placing the support bracket as a whole into a dynamic culture syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com