Preparation method of Ag/g-C3N4 composite visible light catalyst

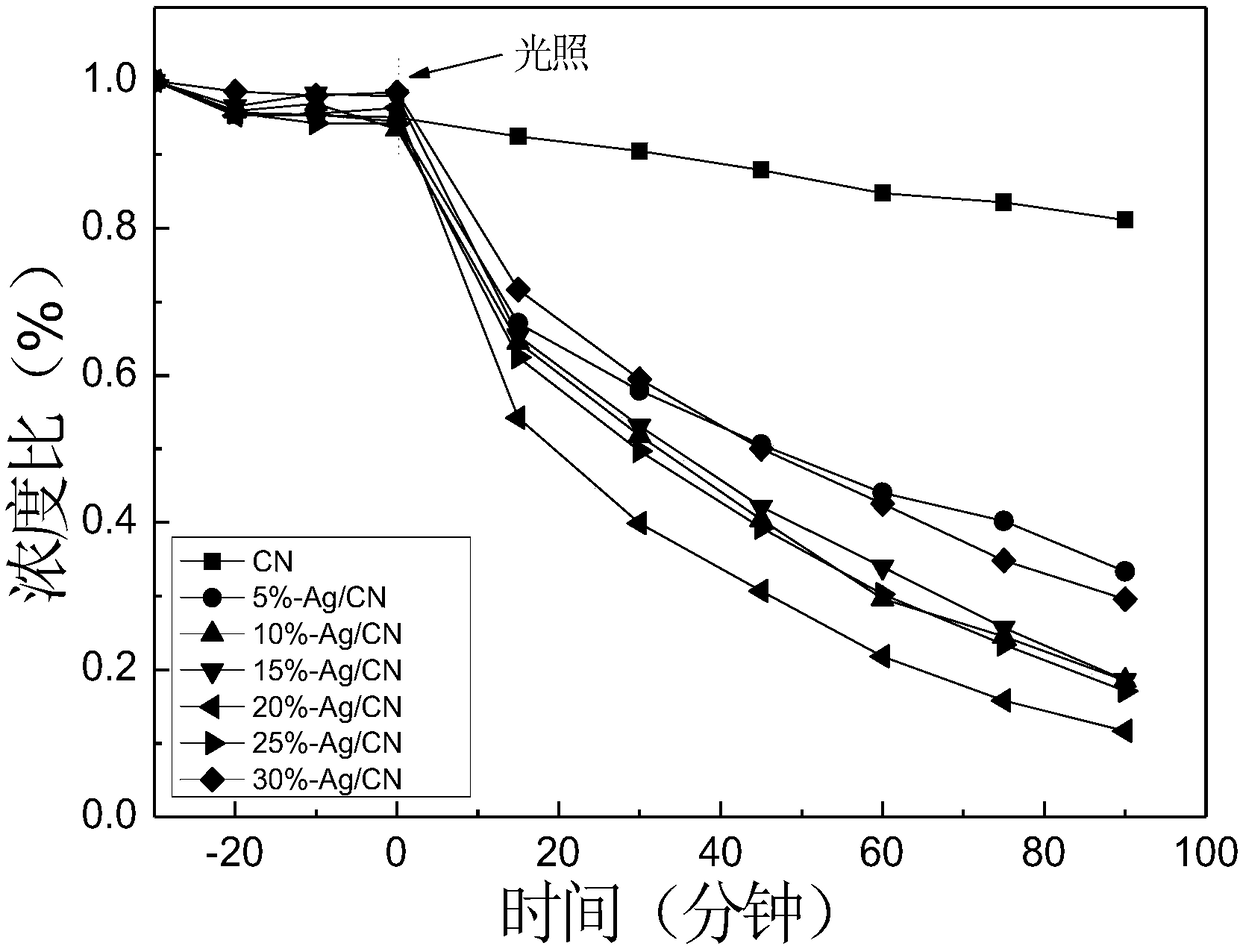

A technology of g-c3n4 and visible light, applied in the field of photocatalysis, can solve the problems of large particle size of Ag particles and complicated preparation process, and achieve the effect of low production cost, good performance and widening the absorption range of visible light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

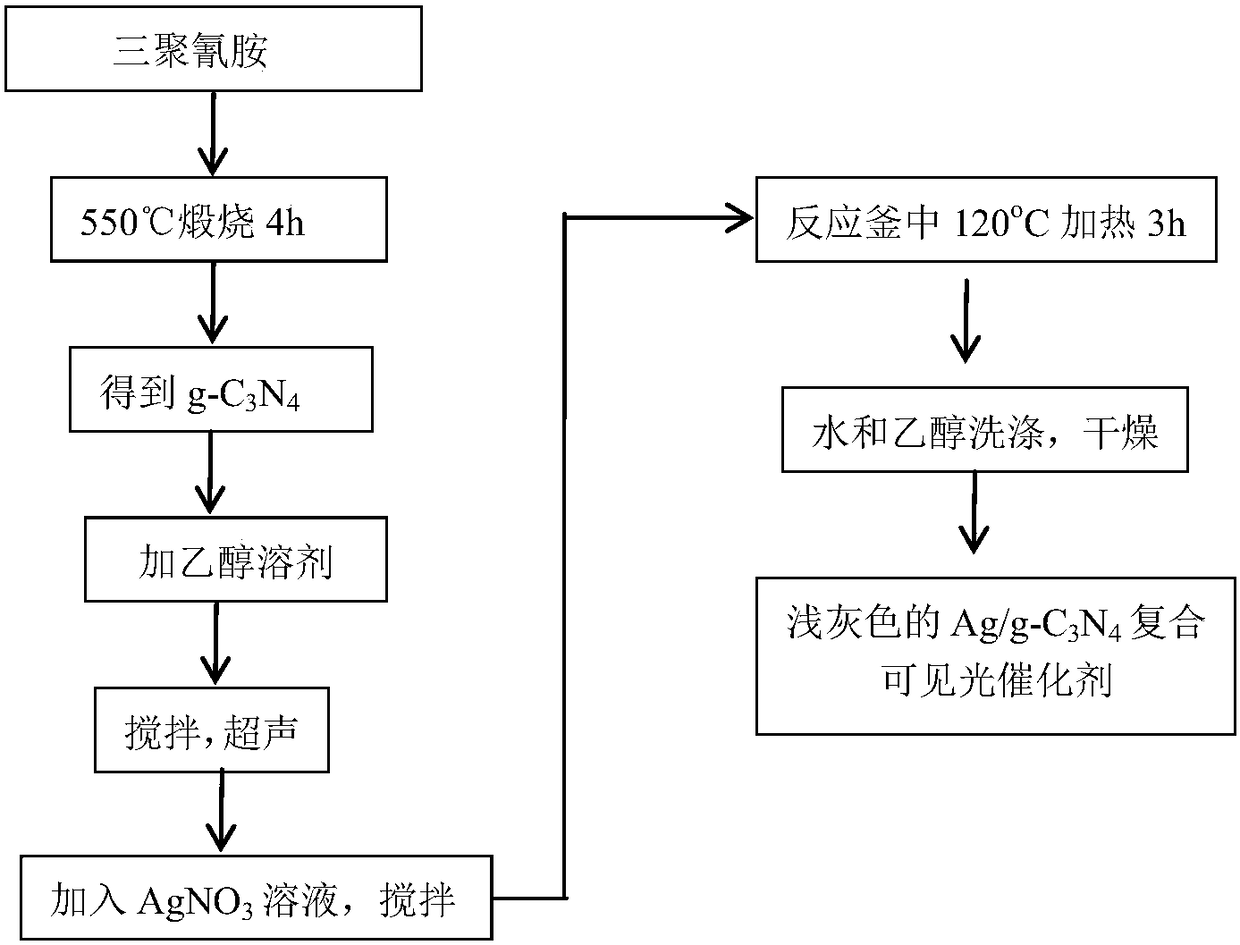

Embodiment 1

[0020] 5%Ag / g-C 3 N 4

[0021] (1) Weigh 1g of g-C 3 N 4 Added to 50mL of ethanol solvent; ultrasonic 30min.

[0022] (2) Add 0.045mol / L AgNO dropwise 3 Solution 10mL, stirred for 30min;

[0023] (3) Pour the prepared solution into a reaction kettle, heat at 120° C. for 3 hours, cool to room temperature, wash with deionized water and absolute ethanol, dry and grind. Obtain light gray 5%Ag / g-C 3 N 4 Composite visible light catalyst.

Embodiment 2

[0025] 10%Ag / g-C 3 N 4

[0026] (1) Weigh 1g of g-C 3 N 4 Added to 50mL of ethanol solvent; ultrasonic 30min.

[0027] (2) Add 0.045mol / L AgNO dropwise 3 Solution 20mL, stirred for 30min;

[0028] (3) Pour the prepared solution into a reaction kettle, heat at 120° C. for 3 hours, cool to room temperature, wash with deionized water and absolute ethanol, dry and grind. Get light gray 10%Ag / g-C 3 N 4 Composite visible light catalyst.

Embodiment 3

[0030] 15%Ag / g-C 3 N 4

[0031] (1) Weigh 1g of g-C 3 N 4 Added to 50mL of ethanol solvent; ultrasonic 30min.

[0032] (2) Add 0.045mol / L AgNO dropwise 3 Solution 30mL, stirred for 30min;

[0033] (3) Pour the prepared solution into a reaction kettle, heat at 120° C. for 3 hours, cool to room temperature, wash with deionized water and absolute ethanol, dry and grind. Get light gray 15%Ag / g-C 3 N 4 Composite visible light catalyst.

[0034] 20%Ag / g-C 3 N 4

[0035] (1) Weigh 1g of g-C 3 N 4 Added to 50mL of ethanol solvent; ultrasonic 30min.

[0036] (2) Add 0.045mol / L AgNO dropwise 3 Solution 40mL, stirred for 30min;

[0037] (3) Pour the prepared solution into a reaction kettle, heat at 120° C. for 3 h, cool to room temperature, wash with deionized water and absolute ethanol, dry and grind. Obtain light gray 20%Ag / g-C 3 N 4 Composite visible light catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com