Method for preparing Au nanoflower through microwave auxiliary method and Au nanoflower

A microwave-assisted, nanoflower technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of high energy efficiency, good monodispersity, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for microwave-assisted preparation of Au nanoflowers, comprising the following steps:

[0034] Step 1, add a certain concentration of HAuCl4 solution in the round bottom flask, then add octadecylamine, KBr and PVP to form mixed solution a;

[0035] Step 2, adding reducing agent tetraethylene glycol (TEG) into mixed solution a, mixing and stirring to obtain mixed solution b;

[0036] Step 3, placing the mixed solution b in a microwave reactor for heating and reacting;

[0037] Step 4, the product of step 3 is treated with acetone to obtain Au nanoflowers;

[0038] Specifically, in the step 1, 5 mL of HAuCl with a concentration of 20 mM was configured 4 solution.

[0039] Further, in the step 1, 2ml of octadecylamine solution with a concentration of 1M was added.

[0040] Further, 20mg of KBr was added in step one.

[0041] Further, the amount of PVP in the first step is 50 mg.

[0042] Further, 20 mL of TEG with a concentration of 0.4 M was added in the se...

Embodiment 2

[0046] A method for microwave-assisted preparation of Au nanoflowers, comprising the following steps:

[0047] Step 1, configure 5 mL of HAuCl with a concentration of 20 mM in a round bottom flask 4 solution; then add 2ml of octadecylamine solution with a concentration of 5M, 20mg of KBr; 50mg of PVP to form a mixed solution a;

[0048] Step 2: Add 20 mL of TEG with a concentration of 0.4M to the mixed solution a, mix and stir to obtain the mixed solution b;

[0049] Step 3, placing the mixed solution b in a microwave reactor with a microwave frequency of 890-2400 MHz and heating it to 180° C., and keeping it for 1 minute for heating and reaction;

[0050] In step 4, the product of step 3 is washed with acetone for 3 to 5 times to obtain Au nanoflowers.

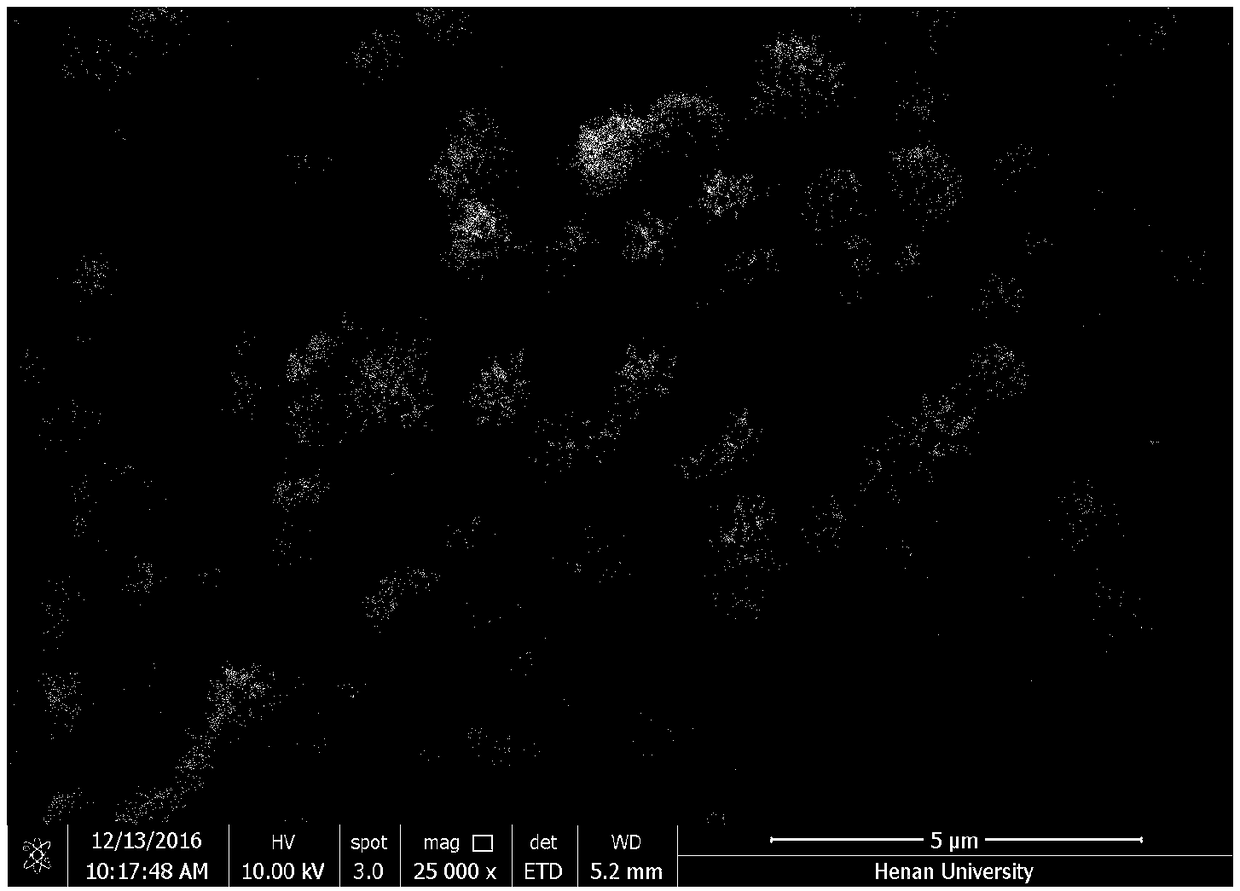

[0051] Such as Figure 4 Shown is the scanning electron microscope image of the Au nanoflowers prepared in this example. The figure shows that the size of the Au nanoflowers is 0.73 μm-1.1 μm, the length of the petals is 0...

Embodiment 3

[0053] A method for microwave-assisted preparation of Au nanoflowers, comprising the following steps:

[0054] Step 1, configure 5 mL of HAuCl with a concentration of 20 mM in a round bottom flask 4 solution; then add 2ml concentration of 1M octadecylamine solution, 20mg of KBr; 100mg of PVP to form a mixed solution a;

[0055] Step 2: Add 20 mL of TEG with a concentration of 0.4M to the mixed solution a, mix and stir to obtain the mixed solution b;

[0056] Step 3, place the mixed solution b in a microwave reactor with a microwave frequency of 890-2400MHz and heat it to 180°C, and keep it for 5 minutes for heating and reaction;

[0057] In step 4, the product of step 3 is washed with acetone for 3 to 5 times to obtain Au nanoflowers.

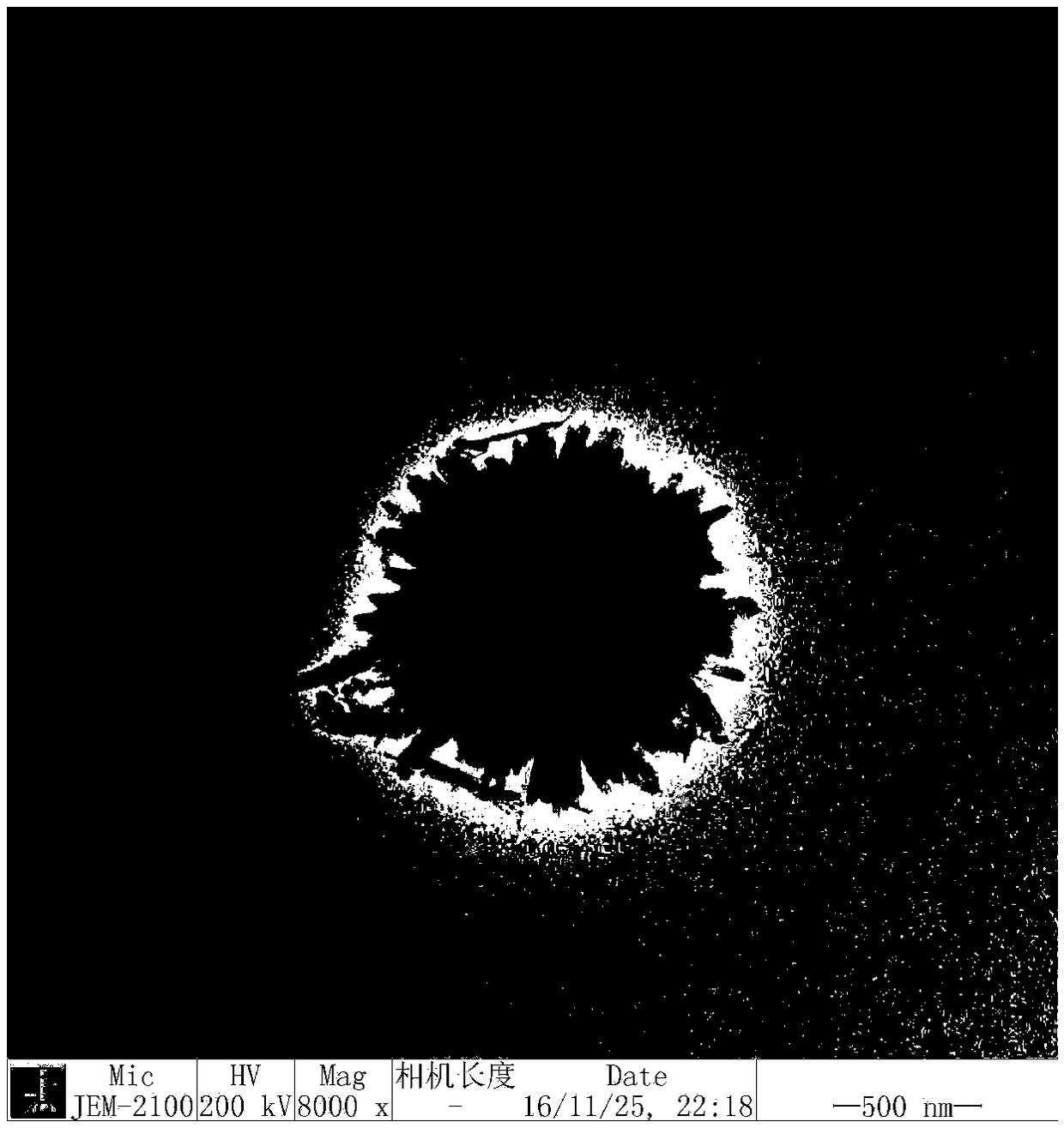

[0058] Such as Figure 5 Shown is the transmission electron microscope image of the Au nanoflowers prepared in this example. It can be seen from the figure that the size of the Au nanoflowers is 1.68 μm-2 μm, the length of the petals is 0.46 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com