Ferrihydrite-ultra-filtration (UF) membrane combination process for removing trivalent arsenic and disinfection by-product precursors

A combined process and trivalent arsenic technology, applied in the field of water treatment, can solve the problems of large pore size of UF membrane, limit the popularization and application of UF membrane, and it is difficult to effectively remove inorganic ions and DBPs precursors, etc., and achieve the effect of reducing the transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

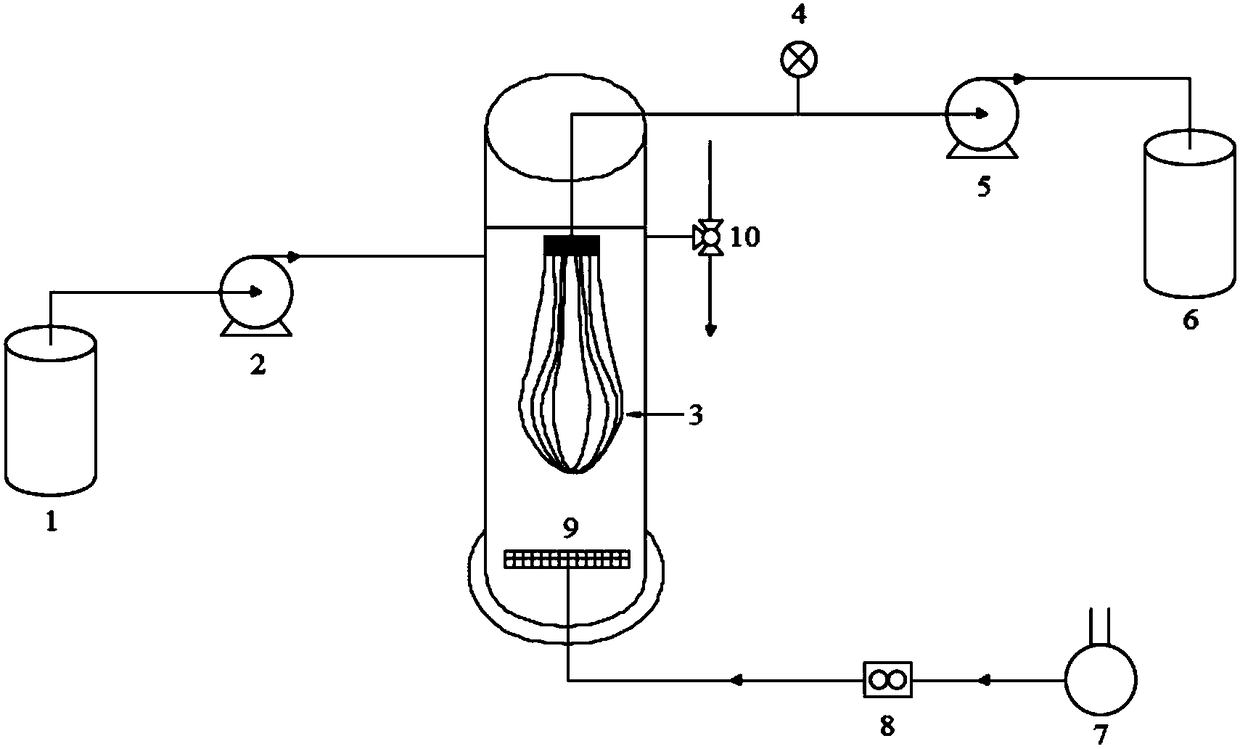

Method used

Image

Examples

Embodiment 1

[0021] In the membrane reaction system, polyvinylidene fluoride UF membrane was used alone without adding adsorbent to remove trivalent arsenic and DOM. Add trivalent arsenic concentration 0.1mg / L and DOM concentration 5.0mg / L to the aqueous solution, at 150L / (m 2 · h) under the condition of constant current operation. DOC removal rate 31.2%, UV 254 The removal rate is 40.1%, the removal rate of THMs precursor is 30.5%, the removal rate of HAAs precursor is 38.6%, and it has no removal effect on trivalent arsenic.

Embodiment 2

[0023] In the membrane reaction system, trivalent arsenic and DOM were removed synergistically by adsorbent FH and polyvinylidene fluoride UF membrane. Add FH concentration 50mg / L-Fe, trivalent arsenic concentration in the feed solution is 0.1mg / L, DOM concentration is 5.0mg / L, at 150L / (m 2 · h) under the condition of constant flow, the transmembrane pressure does not change much during the operation. DOC removal rate 80.3%, UV 254 The removal rate is 91.4%, the removal rate of trivalent arsenic is 99.4%, and the concentration of trivalent arsenic in the effluent is lower than 0.01mg / L, meeting the drinking water standard.

Embodiment 3

[0025] Wipe off the DOM and adsorbent particles accumulated on the surface of the FH-UF membrane after filtration, and then backwash. Macromolecular DOM is the main pollutant that causes UF membrane fouling, and FH has a strong adsorption capacity for macromolecular DOM. After FH was added, a large amount of DOM was adsorbed, and a loose filter cake layer was formed on the membrane surface, which reduced the transmembrane pressure difference by 76.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com