Membrane bioreactor and membrane fouling control device and method for membrane bioreactor

A membrane bioreactor and control device technology, applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc. cost and other issues, to achieve the effect of reducing membrane fouling, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

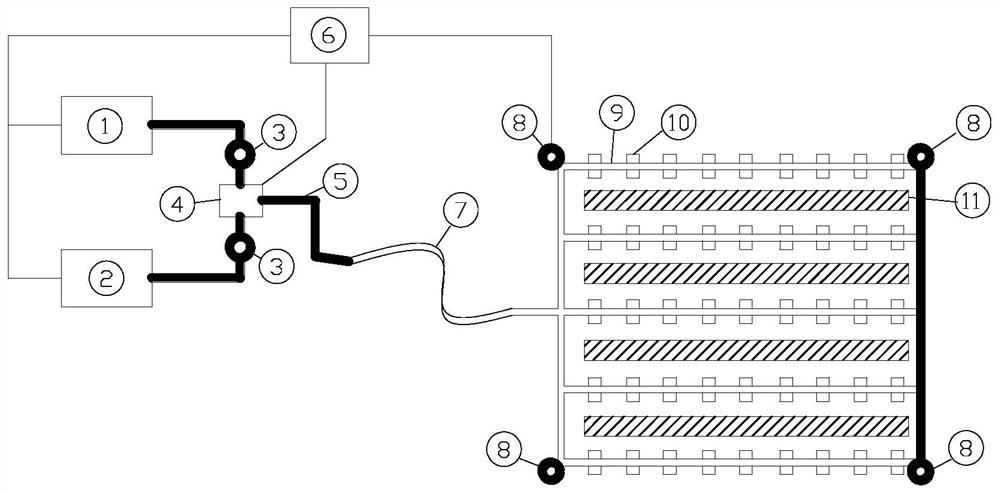

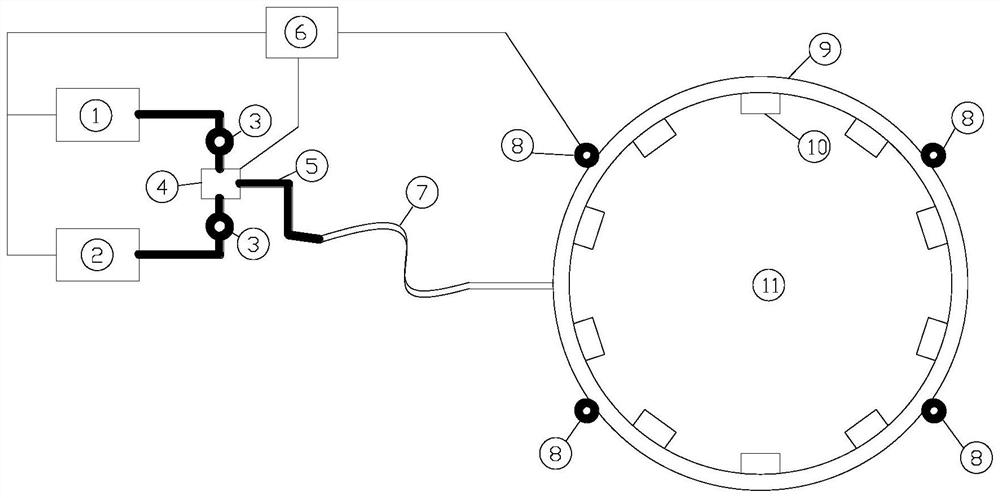

[0045] A scanning type membrane bioreactor membrane pollution control device, comprising a fluid medium (water or air) injection system, provided with a lifting system and a control system of the injection device; a fluid medium comprising a water injection system of the compressor, air compressors, rigidly connected 5 pipe, flexible pipe is connected, the gas and the liquid pipe 4 and the switching means 3 a check valve, pressure conduit 10 and the nozzle; the lifting means comprises hydraulic or mechanical lifting system, the fluid injection system is fixed to the medium lift system, with the lifting system run up and down reciprocation; fluid medium injection system and lift control system programmed by computer control system, while designed for manual control cabinet, the control content switching medium comprising ejection, the ejection pressure adjustment, the injection time control, the lifting speed and time control, and hoist system reciprocation frequency control interv...

Embodiment 2

[0054] A membrane bioreactor membrane pollution control method for controlling contamination in situ anaerobic MBR membrane, comprising the steps of:

[0055] 1) The programming or manually, according to the cleaning requirements membrane module, periodically opening the lifting device, spraying high-pressure water injection system, according to the operating conditions to optimize the transmembrane pressure or to select the number of reciprocating motion and injection pressure;

[0056] 2) When the membrane flux and transmembrane pressure required to achieve the desired reciprocating motion is stopped, the injection device is reset to the bottom of MBR systems;

[0057] 3) the injection device is reset, conventional injection water, the active sludge was stirred strength requirements set injection;

[0058] 4) during operation may take a conventional cleaning procedures, i.e., when the membrane module periodically reciprocating cleaning unsoiled;

[0059] 5) reaches serious membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com