Anti-erosion blast furnace iron runner self-flowing castable and preparation method thereof

A castable and corrosion-resistant technology, which is applied in the field of refractory materials, can solve the problems of increasing the labor intensity of workers in front of the furnace, shortening the service life of iron trench materials, and increasing slag erosion, so as to enhance the slag erosion resistance and improve The effect of one-pass iron quantity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

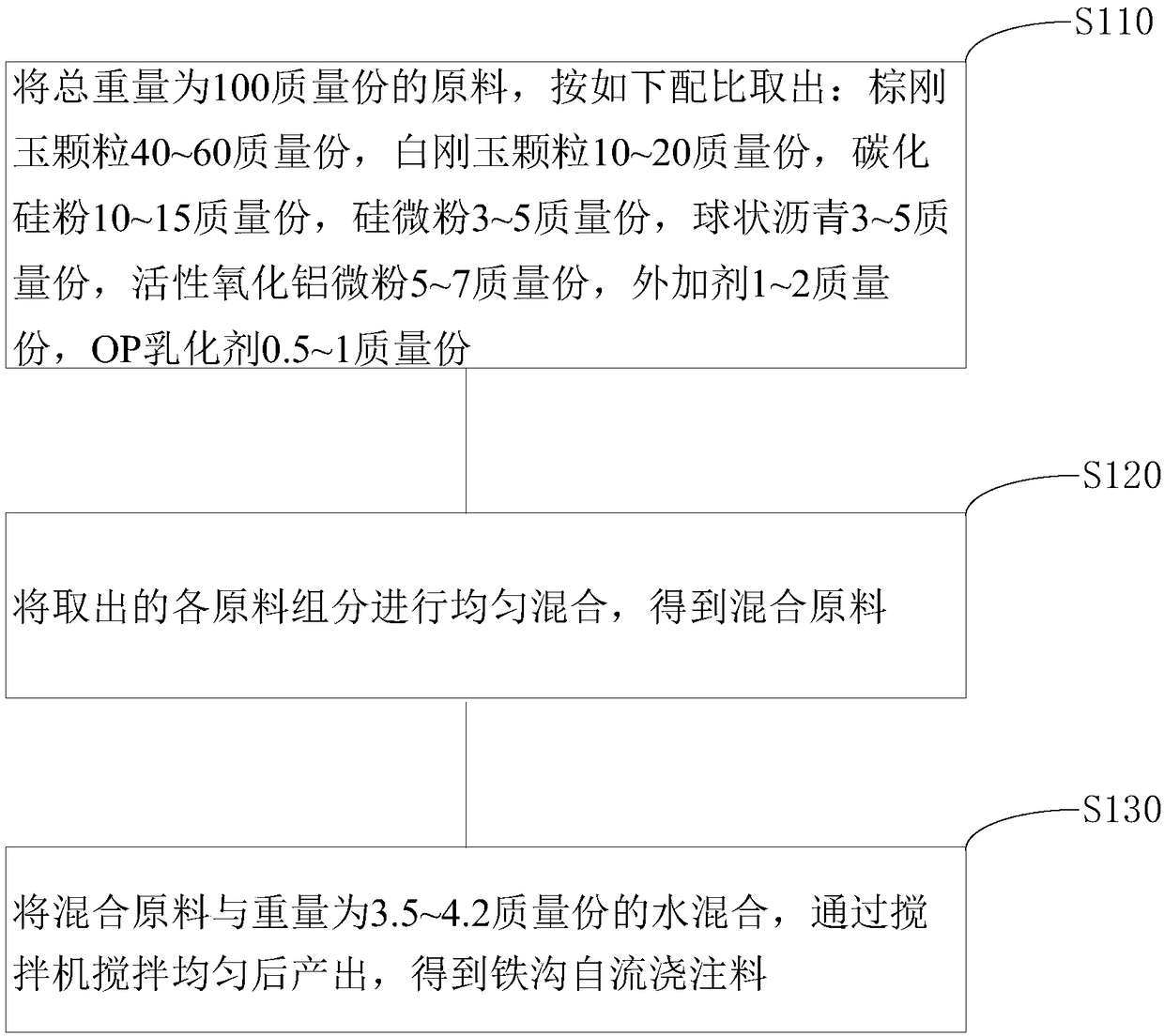

Method used

Image

Examples

Embodiment 1

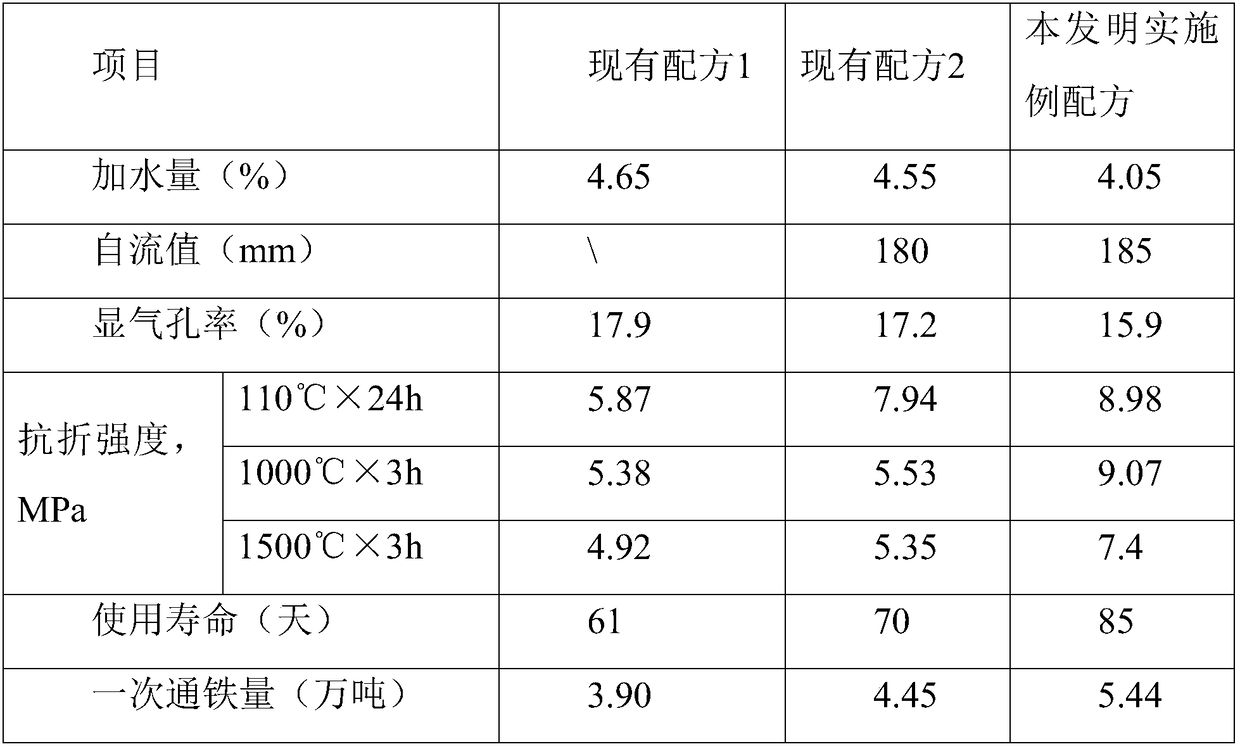

[0032] The embodiment of the present invention provides an erosion-resistant self-flowing castable for blast furnace iron trough and its preparation method, which solves the problems of high porosity and poor material compactness caused by excessive water consumption in the current preparation process of blast furnace iron trough.

[0033] In one aspect of the embodiments of the present invention, an erosion-resistant self-flowing castable for blast furnace iron trough is provided.

[0034] The raw material composition and mass ratio of an erosion-resistant self-flowing castable for blast furnace iron trough provided by the embodiment of the present invention are as follows: 40-60 parts by mass of brown corundum particles, 10-20 parts by mass of white corundum particles, 10-20 parts by mass of silicon carbide powder 15 parts by mass, 3-5 parts by mass of silicon micropowder, 3-5 parts by mass of spherical pitch, 5-7 parts by mass of activated alumina micropowder, 1-2 parts by m...

Embodiment 2

[0047] This embodiment provides an erosion-resistant self-flowing castable for blast furnace iron trough, the proportion of each component is: 45 parts by mass of brown corundum particles, 18 parts by mass of white corundum particles, 14 parts by mass of silicon carbide powder, and 5 parts by mass of silicon micropowder parts, 4 parts by mass of spherical pitch, 7 parts by mass of activated alumina micropowder, 2 parts by mass of admixture, and 0.8 parts by mass of OP emulsifier.

[0048] Among them, the OP emulsifier is the condensation product of alkylphenol and ethylene oxide, and the model is OP-15.

[0049] The particle size of brown corundum particles is 5-8mm and 3-5mm, Al 2 o 3 The mass percentage is greater than or equal to 90%.

[0050] The particle diameters of the white corundum particles are 1-3mm and 0.074-1mm. al 2 o 3 The mass percentage is greater than or equal to 90%.

[0051] The particle size of silicon carbide powder is 0.074-1mm and 0-0.074mm, and t...

Embodiment 3

[0055] This embodiment provides an erosion-resistant self-flowing castable for blast furnace iron trough. The proportion of each component is: 42 parts by mass of brown corundum particles, 20 parts by mass of white corundum particles, 14.5 parts by mass of silicon carbide powder, and 4 parts by mass of silicon micropowder parts, 3 parts by mass of spherical pitch, 6.5 parts by mass of activated alumina micropowder, 1.5 parts by mass of admixture, and 0.55 parts by mass of OP emulsifier.

[0056] Among them, the OP emulsifier is the condensation product of alkylphenol and ethylene oxide, and the model is OP-20.

[0057] The particle size of brown corundum particles is 5-8mm and 3-5mm, Al 2 o 3 The mass percentage is greater than or equal to 90%.

[0058] The particle diameters of the white corundum particles are 1-3mm and 0.074-1mm. al 2 o 3 The mass percentage is greater than or equal to 90%.

[0059] The particle size of silicon carbide powder is 0.074-1mm and 0-0.074mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com