High-mass sintered diamond drill bit for processing aluminum oxide ceramic and preparation method of high-mass sintered diamond drill bit

A technology of diamond drill bits and alumina ceramics is applied in the field of mechanical processing and manufacturing, which can solve problems such as affecting the quality of hole processing, and achieve the effects of improving processing quality, reducing chipping depth and reducing stretching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The carcass raw materials are: 56 parts of pure Fe powder, 16 parts of pure Cu powder, 16 parts of pure Ni powder, 8 parts of pure Sn powder, and 4 parts of pure Ti powder.

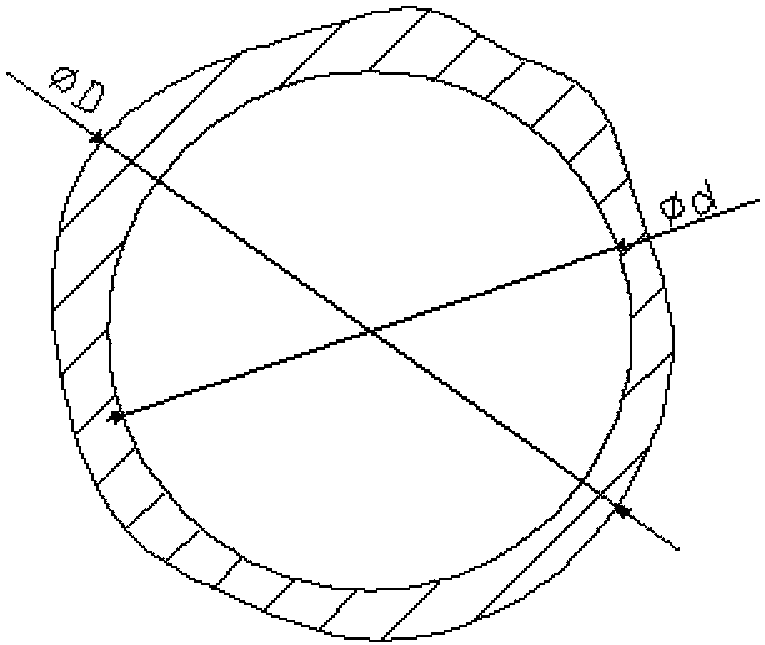

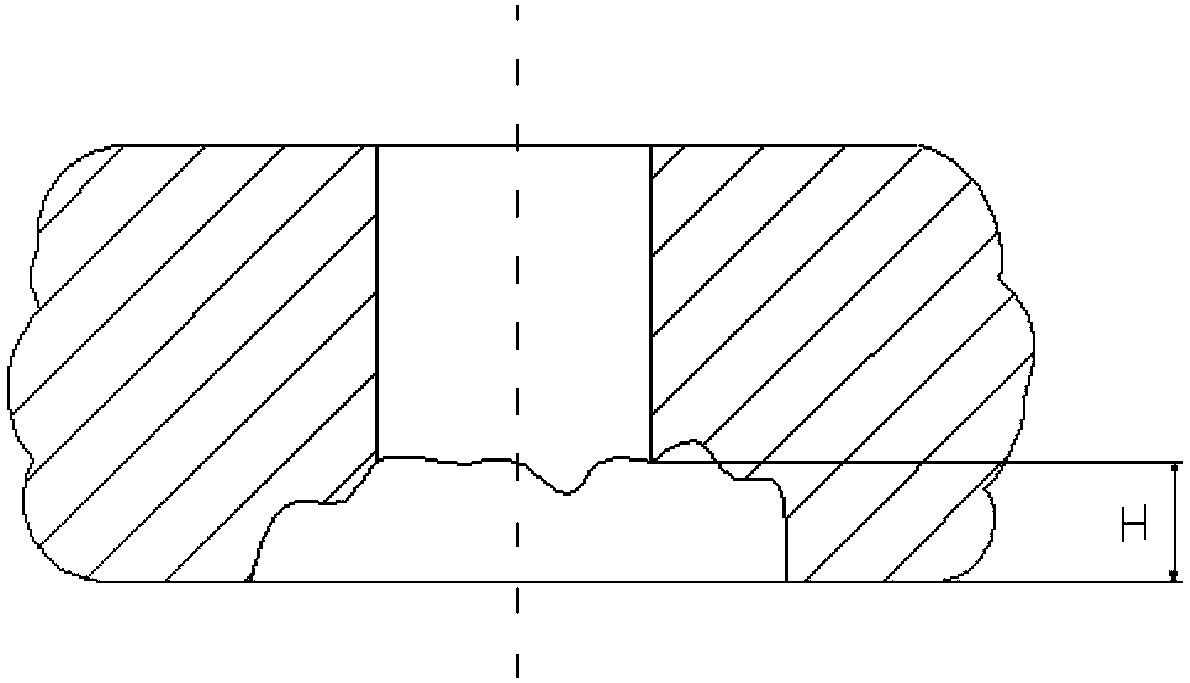

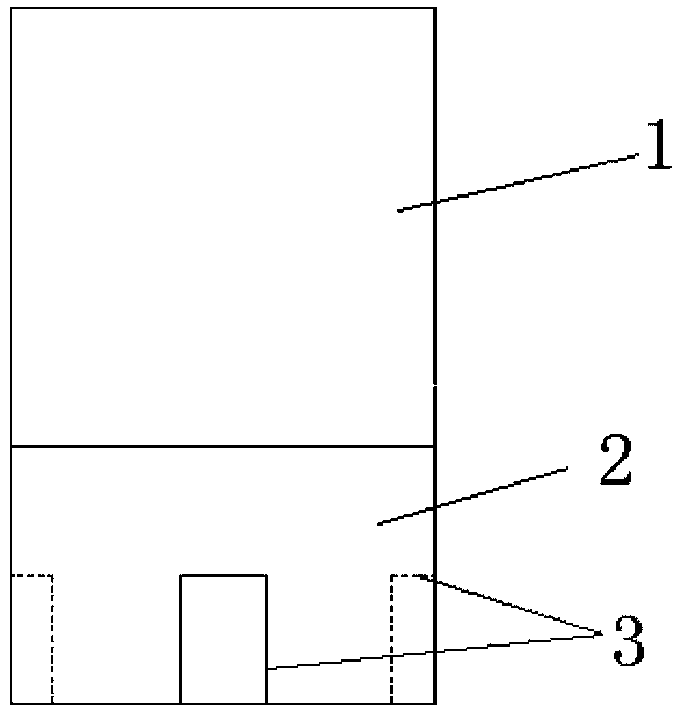

[0044] Such as image 3As shown, the high-quality sintered diamond drill bit prepared by the present invention is composed of a substrate 1 and a diamond sintered body 2, and a nozzle 3 is provided on the diamond sintered body 2, and the diamond sintered body 2 is composed of a sintered diamond bit matrix and a diamond sintered body 2. The diamond abrasive grains are mixed and sintered. Among them, the working layer height of the drill bit is 4.2mm, the wall thickness is 3.5mm, the drill bit diameter is 26mm, the nozzle number is 4, the diamond grain size is 80 / 100, and the diamond abrasive grain concentration is 83%.

[0045] The preparation method of the sintered diamond drill includes: firstly selecting a suitable metal substrate, processing it into the required shape and size, and preparing a m...

Embodiment 2

[0048] The carcass raw materials are: 62 parts of pure Fe powder, 16 parts of pure Cu powder, 12 parts of pure Ni powder, 4 parts of pure Sn powder, and 6 parts of pure Ti powder.

[0049] The structural parameters of the sintered diamond drill bit are: the working layer height of the drill bit is 4.5mm, the wall thickness is 3.8mm, the drill bit diameter is 29mm, the nozzle number is 4, the diamond particle size is 100 / 120, and the diamond concentration is 89%.

[0050] The preparation method of the sintered diamond drill includes: firstly selecting a suitable metal substrate, processing it into the required shape and size, and preparing a mold for placing the matrix according to the working layer height, wall thickness, diameter and nozzle of the sintered diamond drill to be prepared; secondly According to the composition of the matrix, prepare the matrix, mix it with diamond abrasive grains, put it into a graphite mold, and carry out hot-pressing sintering at a sintering tem...

Embodiment 3

[0053] Design 6 groups of parallel experiments, the basic steps are the same as in Example 1, the difference is only the raw material components of the carcass, which are respectively:

[0054] 1. 55 parts of pure Fe powder, 15 parts of pure Cu powder, 17 parts of pure Ni powder, 8 parts of pure Sn powder, and 5 parts of pure Ti powder.

[0055] 2. 57 parts of pure Fe powder, 17 parts of pure Cu powder, 16 parts of pure Ni powder, 4 parts of pure Sn powder, 6 parts of pure Ti powder.

[0056] 3. 58 parts of pure Fe powder, 18 parts of pure Cu powder, 14 parts of pure Ni powder, 5 parts of pure Sn powder, and 5 parts of pure Ti powder.

[0057] 4. 59 parts of pure Fe powder, 19 parts of pure Cu powder, 13 parts of pure Ni powder, 5 parts of pure Sn powder, and 4 parts of pure Ti powder.

[0058] 5. 61 parts of pure Fe powder, 18 parts of pure Cu powder, 14 parts of pure Ni powder, 5 parts of pure Sn powder, and 3 parts of pure Ti powder.

[0059] 6. 63 parts of pure Fe powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com