Back rubber waterproof jet-drawing painting canvas and production method thereof

An oil painting cloth and inkjet technology, applied in painting tools, varnished cloth, decorative art, etc., can solve the problems of easy wrinkling, poor inkjet effect and waterproof effect, etc., and achieve the effect of not easy to fade, beautiful color, and good ink absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

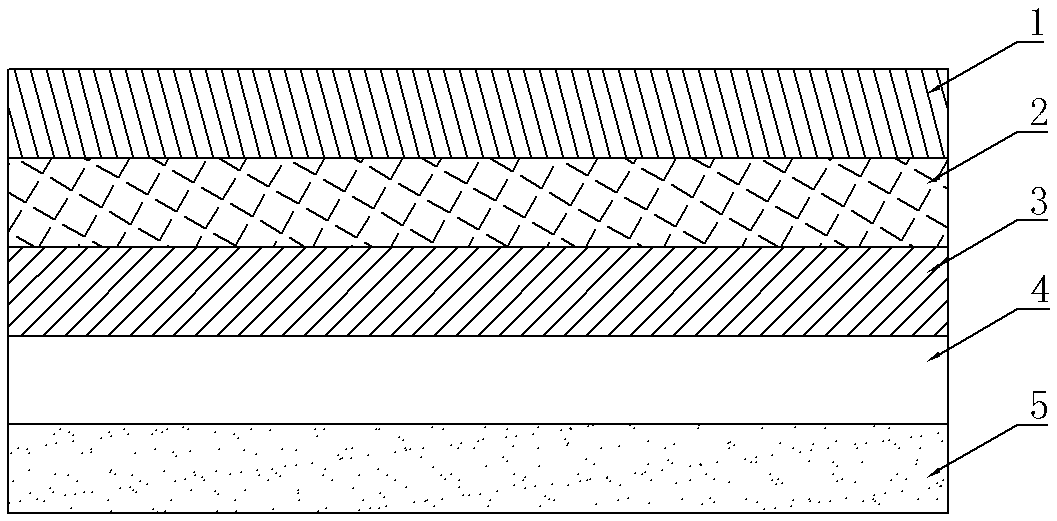

[0019] Such as figure 1 As shown, a self-adhesive waterproof inkjet oil canvas, which includes an ink-absorbing surface layer 1, an ink-absorbing middle layer 2, an ink-absorbing inner layer 3, a base material 4 and an adhesive layer 5 arranged from top to bottom,

[0020] The ink-absorbing surface layer 1 includes the following raw materials in parts by weight, 35 parts of vinyl acetate emulsion, 18 parts of natural stone powder, 6.5 parts of polyvinyl alcohol, 3.8 parts of powdery silicon dioxide, and 4.3 parts of cationic water-based polyurethane color-fixing agent;

[0021] The ink-absorbing middle layer 2 includes the following raw materials in parts by weight, 30 parts of vinyl acetate emulsion, 16 parts of natural stone powder, and 4 parts of polyvinyl alcohol;

[0022] The ink-absorbing inner layer 3 includes the following raw materials in parts by weight, 35 parts of vinyl acetate emulsion, and 18 parts of natural stone powder;

[0023] The base material 4 is a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com