Method for determining copper ion concentration by means of ionic liquid extraction differential pulse voltammetry

A differential pulse voltammetry and ionic liquid technology, applied in the field of electrochemical analysis and detection, can solve the problems of long operation time, large amount of organic solvent, complicated operation steps, etc., and achieve the effects of high sensitivity, reduced pollution and low detection limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

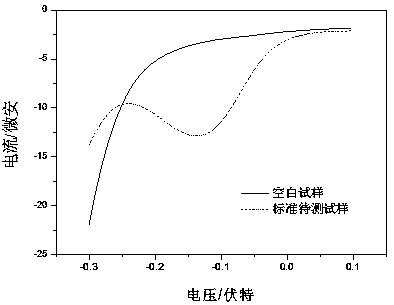

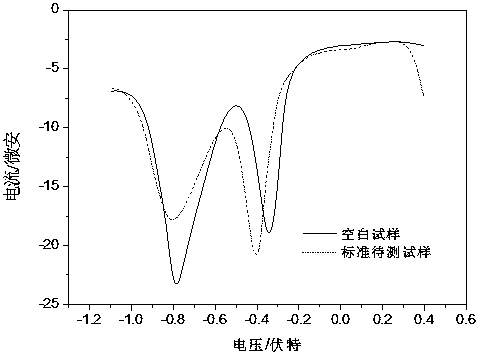

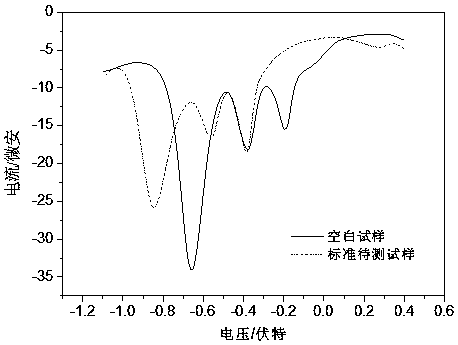

[0022] (1) Weigh 0.0938 g copper nitrate solid, add deionized water to dissolve completely, transfer to a 50 mL volumetric flask with glass rod drainage, dilute to the mark with deionized water, shake well, and obtain a concentration of 0.01 mol / L Copper nitrate solution, the 0.01 mol / L copper nitrate solution was diluted step by step to obtain a concentration of 6×10 -4 mol / L, 3.6×10 -4 mol / L, 1.8×10 -4 mol / L, 6×10 -5 mol / L, 4.8×10 -5 mol / L, 2.4×10 -5 mol / L and 1.2×10 -5 mol / L series of low-concentration copper ion solutions.

[0023] (2) Pipette 150 μL of the low-concentration copper ion solution prepared in step (1) into seven 1.5 mL centrifuge tubes, and then respectively pipette 600 μL of NH solution with pH=8.0 3 -NH 4 Cl buffer and 150 μL at a concentration of 6×10 -3 mol / L PAN-ethanol solution, shake the centrifuge tube for 15 s and let it stand still.

[0024] (3) Use a pipette gun to pipette 50 μL of ionic liquid 1-butyl-3-methylimidazolium hexafluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com