Imidapril hydrochloride tablet and preparation method thereof

A technology of imidapril hydrochloride tablets and imidapril hydrochloride, which is applied in the directions of pill delivery, dipeptide components, cardiovascular system diseases, etc., can solve the problems of uneven content distribution, long production time and high risk, Achieve the effect of shortening production time, improving production efficiency and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

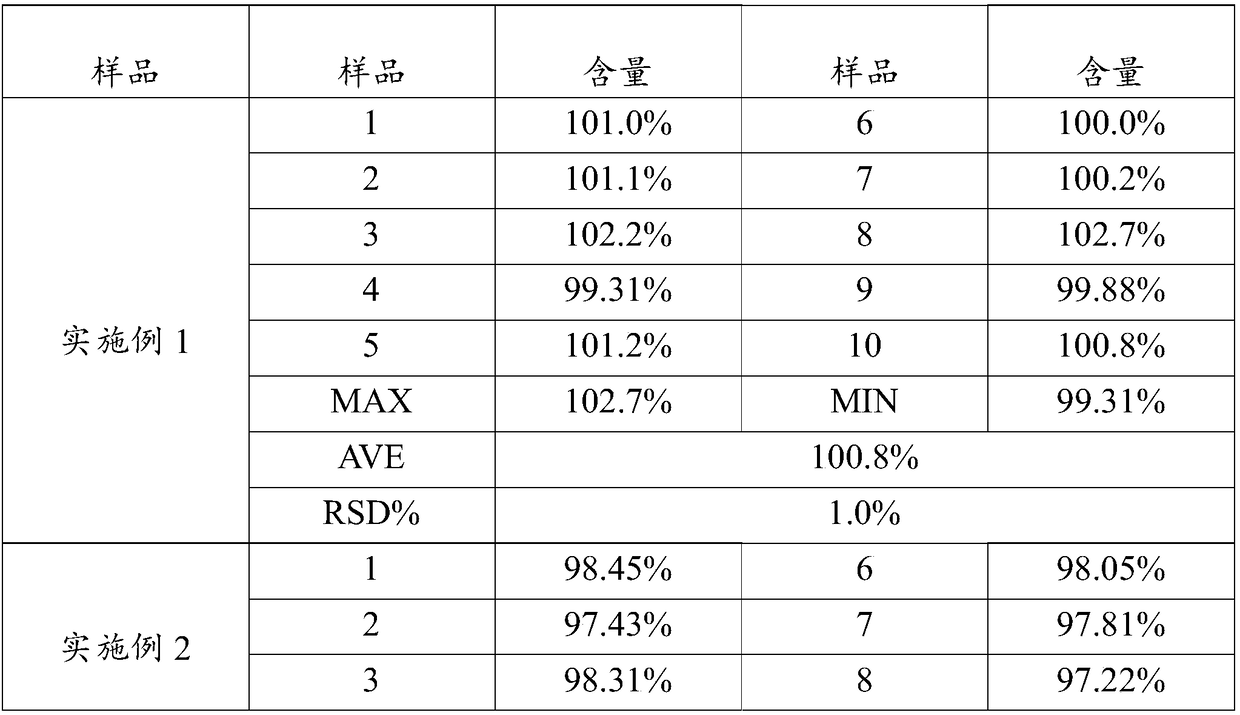

Embodiment 1

[0024] The present embodiment provides a kind of imidapril hydrochloride tablet, and raw material component comprises:

[0025] Imidapril hydrochloride 5mg, lactose 100mg, polyethylene glycol 6000 12mg, micronized silica gel 0.2mg.

[0026] Further, a method for preparing the imidapril hydrochloride tablet is provided, comprising the steps of:

[0027] (1) Take imidapril hydrochloride and lactose respectively, pulverize and sieve to obtain fine powders of each raw material with a particle size of 0.074mm, and after fully mixing the fine powders of each raw material, obtain a mixed medicinal powder; weigh polyethylene glycol 6000, after mixing with pure water at a mass ratio of 400:219 (pure water: polyethylene glycol 6000), an aqueous binder solution is obtained;

[0028] (2) Put the mixed drug powder into a fluidized bed granulator, feed high-temperature gas heated to 65°C for preheating, and when the exhaust gas temperature reaches 35°C, start to spray the aqueous binder so...

Embodiment 2

[0032] The present embodiment provides a kind of imidapril hydrochloride tablet, and raw material component comprises:

[0033] Imidapril hydrochloride 10mg, lactose 110mg, polyethylene glycol 6000 16mg, micropowder silica gel 0.4mg.

[0034] Further, a method for preparing the imidapril hydrochloride tablet is provided, comprising the steps of:

[0035] (1) Take imidapril hydrochloride and lactose respectively, pulverize and sieve to obtain fine powders of each raw material with a particle size of 0.065mm, and after fully mixing the fine powders of each raw material, obtain a mixed medicinal powder; weigh polyethylene glycol 6000, after mixing with pure water in a mass ratio of 600:219 (pure water: polyethylene glycol 6000), an aqueous binder solution is obtained;

[0036] (2) Put the mixed drug powder into a fluidized bed granulator, feed high-temperature gas heated to 75°C for preheating, and when the exhaust gas temperature reaches 45°C, start to spray the aqueous binder ...

Embodiment 3

[0040] The present embodiment provides a kind of imidapril hydrochloride tablet, and raw material component comprises:

[0041] Imidapril hydrochloride 5mg, lactose 105mg, polyethylene glycol 6000 13mg, micropowder silica gel 0.25mg.

[0042] Further, a method for preparing the imidapril hydrochloride tablet is provided, comprising the steps of:

[0043] (1) Take imidapril hydrochloride and lactose respectively, pulverize and sieve to obtain fine powders of each raw material with a particle size of 0.057mm, and after fully mixing the fine powders of each raw material, obtain a mixed medicinal powder; weigh polyethylene glycol 6000, after mixing with pure water at a mass ratio of 500:219 (pure water: polyethylene glycol 6000), an aqueous binder solution is obtained;

[0044] (2) Put the mixed drug powder into a fluidized bed granulator, feed high-temperature gas heated to 68°C for preheating, and when the exhaust gas temperature reaches 39°C, start to spray the aqueous binder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com