Preparation method of chitosan-based cationic gemini asphalt emulsifier

An asphalt emulsifier, cationic technology, used in building components, building insulation materials, buildings, etc., to achieve the effects of low CMC value, high surface activity, and low usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Emulsifier preparation: 16.1g (0.1mol) chitosan and 48.0g water were added to the reaction device, stirred and dissolved at 150rpm, and 8.71g (0.05mol) of ethylene glycol diglycidyl ether was added dropwise at 75°C, controlled The dropping rate is 1 drop / 2 seconds, and the reaction is refluxed for 5 hours after the dropping. After the reaction, the water is removed by centrifugation to obtain a flocculent solid substance, that is, a chitosan-based cationic gemini asphalt emulsifier, and the product yield is 96.2%.

[0020] Preparation of emulsifier aqueous solution: Dissolve 4.0 g of the emulsifier into 160 g of hot water at about 75° C., add an appropriate amount of concentrated hydrochloric acid to adjust the pH of the solution to 3-4, and obtain an emulsifier aqueous solution.

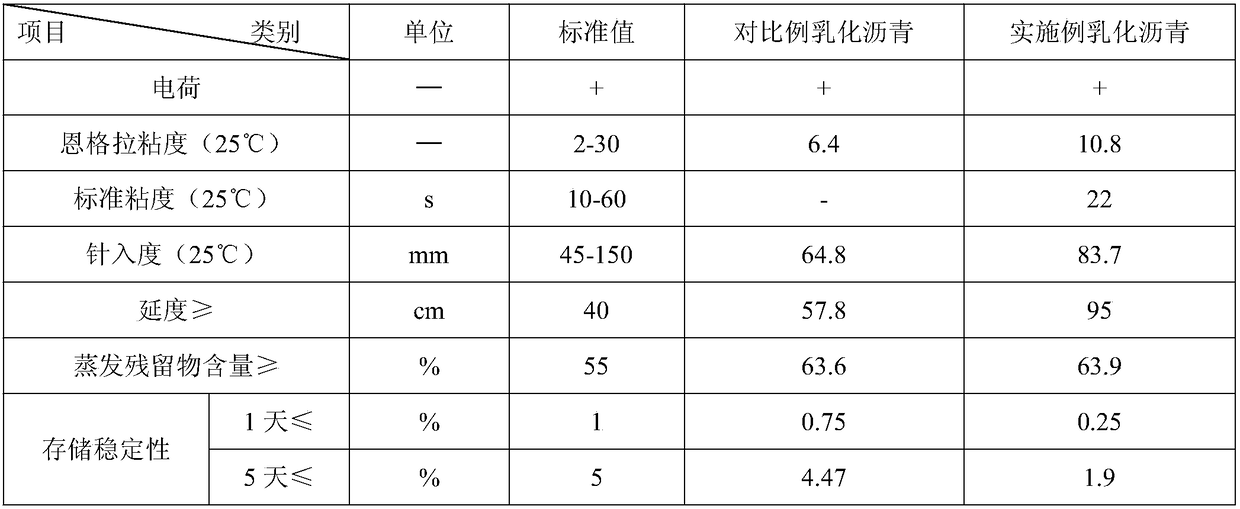

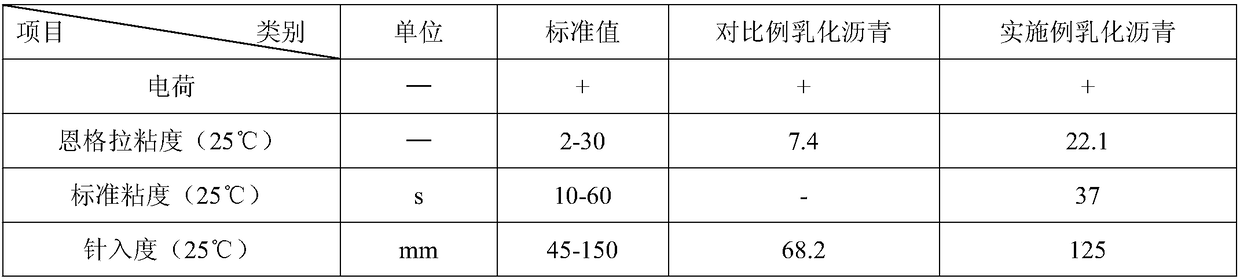

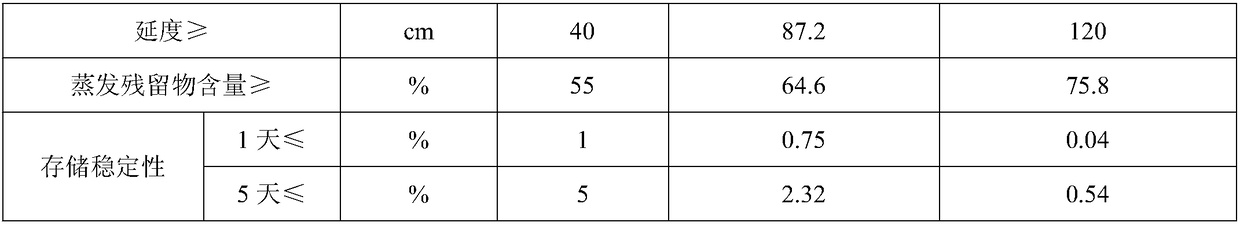

[0021] Asphalt emulsion preparation: Start the colloid mill, add the above-mentioned emulsifier aqueous solution at about 75°C to the colloid mill for saponification, then continuously add pet...

Embodiment 2

[0027] Emulsifier preparation: Add 16.1g (0.1mol) chitosan and 48.0g water into the reaction device, stir and dissolve at 150rpm, add 5.1g (0.025 mol), the control rate of addition is 1 drop / 3 seconds, the dropwise addition is completed and the reflux reaction is 6h. After the reaction is completed, the water is removed by centrifugation to obtain a flocculent solid substance, that is, to obtain a chitosan-based cationic gemini bituminous emulsifier, and the product yield is 93.7 %.

[0028] Preparation of emulsifier aqueous solution: preparation by referring to the method in Example 1.

[0029] Preparation of bitumen emulsion: prepared according to the method in Example 1.

Embodiment 3

[0036] Emulsifier preparation: 16.1g (0.1mol) chitosan and 48.0g water were added to the reaction device, stirred and dissolved at 150rpm, and 5.8g (0.05 mol), control the dropping speed to be 1 drop / 4 seconds, drop and complete the reflux reaction for 8h, and centrifuge to remove water after the reaction, to obtain flocculent solid matter, that is, to obtain the chitosan-based cationic gemini asphalt emulsifier, and the product yield is 93.5 %.

[0037] Preparation of emulsifier aqueous solution: preparation by referring to the method in Example 1.

[0038] Preparation of bitumen emulsion: prepared according to the method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com