Anti-crease finishing method for improving strength and hand feeling of cotton fabric

A technology of anti-wrinkle finishing and cotton fabric, applied in the direction of improved hand fiber, fiber treatment, plant fiber, etc., can solve the problems of cotton fabric strength decline, large amount of reagents, complicated process, etc., to improve quality, improve hand feel, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

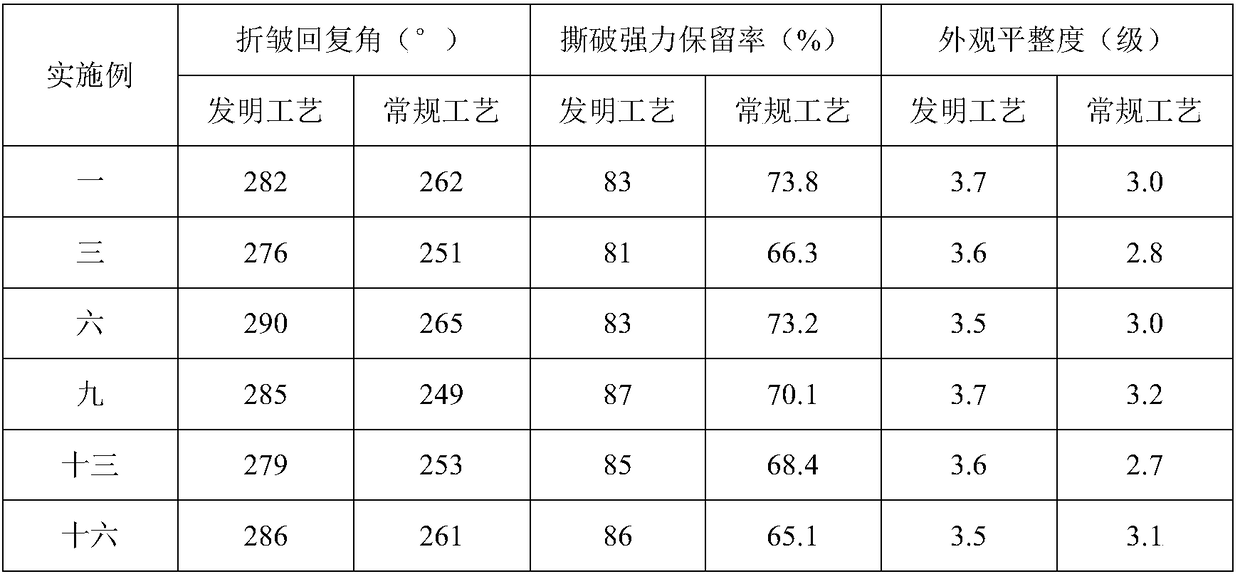

Examples

Embodiment 1

[0039] According to the above process steps: select the scouring and non-ironing cotton fabric as the fabric to be finished, place the scouring and non-ironing cotton fabric in liquid ammonia for padding liquid ammonia treatment, wherein the padding time is 0.1 minute , the paddle pressure is 0.2Mpa, and the fabric pretension is 0.1kg / cm 3 . Put the cotton fabrics treated with liquid ammonia in N-methylol resin for heavy-duty non-ironing finishing, wherein the cotton fabrics after padding with N-methylol resin are pre-dried at 40°C and baked at 160°C for later use . Put the cotton fabric after heavy non-iron finishing in liquid ammonia for heavy liquid ammonia finishing, wherein the padding time is 30 minutes, the padding pressure is 0.05Mpa, and the fabric pretension is 0.5kg / cm 3 .

Embodiment 2

[0041] According to the above process steps: select the cotton fabric after scouring, bleaching and non-ironing as the fabric to be finished, place the cotton fabric after scouring, bleaching and non-ironing in liquid ammonia for padding liquid ammonia treatment, wherein, padding The time is 30 minutes, the padding pressure is 0.05Mpa, and the fabric pretension is 0.5kg / cm 3 . Put the cotton fabrics treated with liquid ammonia in N-methylol resin for heavy-duty non-ironing finishing, wherein the cotton fabrics after padding with N-methylol resin are pre-dried at 60°C and baked at 120°C for later use . Put the cotton fabric after heavy non-ironing finishing in liquid ammonia for heavy liquid ammonia finishing, wherein the padding time is 0.1 minute, the padding pressure is 0.2Mpa, and the fabric pretension is 0.1kg / cm 3 .

Embodiment 3

[0043] According to the above process steps: select the cotton fabric after scouring, bleaching, mercerizing and non-ironing as the fabric to be finished, place the cotton fabric after scouring, bleaching, mercerizing and non-ironing in liquid ammonia for padding liquid ammonia treatment, Among them, the padding time is 15 minutes, the padding pressure is 0.1Mpa, and the fabric pre-tension is 0.3kg / cm 3 . Put the cotton fabric treated with liquid ammonia in N-methylol resin for heavy non-ironing finishing, roll the cotton fabric after padding with N-methylol resin, and store it at 24°C for 48 hours before use. Put the cotton fabric after heavy non-ironing finishing in liquid ammonia for heavy liquid ammonia finishing, wherein the padding time is 10 minutes, the padding pressure is 0.15Mpa, and the fabric pretension is 0.5kg / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com