Structure of composite reinforcement pile capable of resisting budge of foundation and construction method

A technology of reinforced piles and foundations, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of large amount of steel bar consumption and high project cost, and achieve the effects of reducing steel bar consumption, saving construction costs, and convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

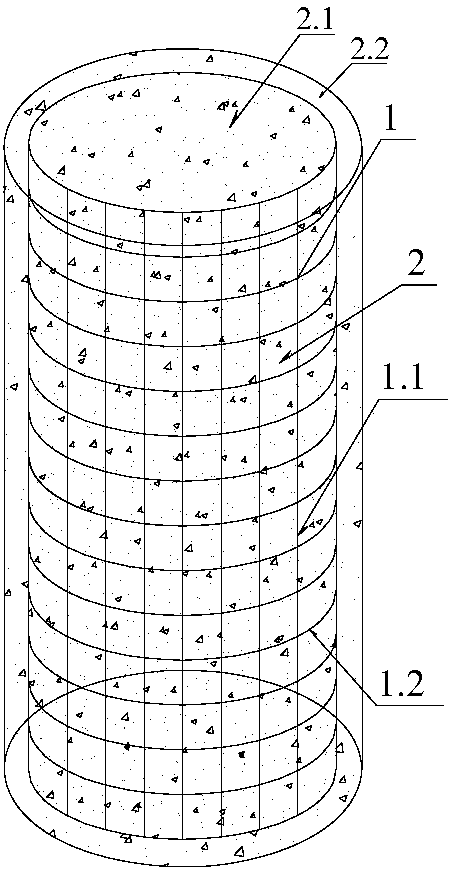

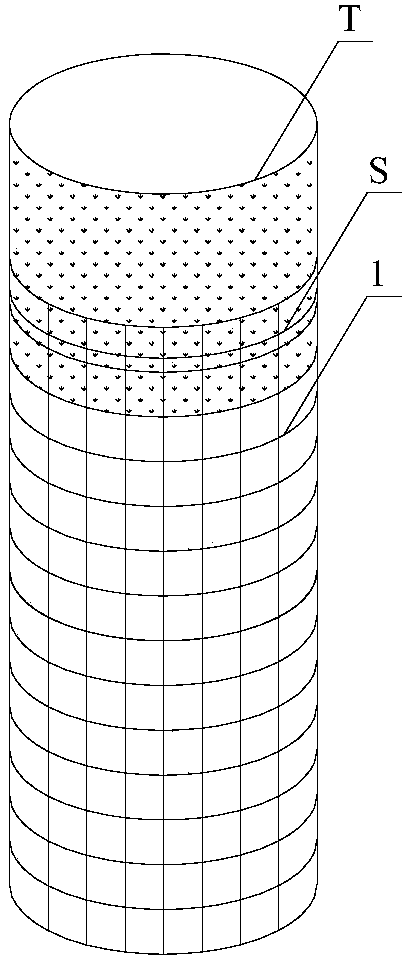

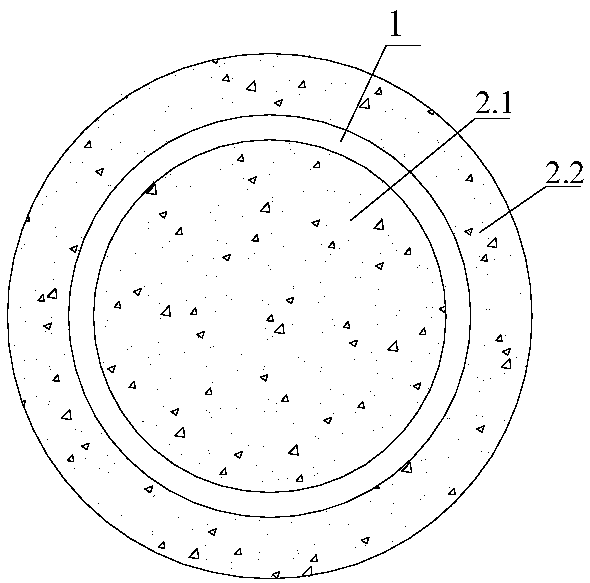

[0019] refer to figure 1 and image 3 , a composite reinforced pile structure resisting foundation uplift of the present invention includes a fine stone concrete pouring body 2 and a composite reinforced cage 1 embedded therein. The composite reinforced cage 1 is composed of vertical geogrids 1.1 arranged at intervals in the circumferential direction and annular geogrids 1.2 arranged at vertical intervals. A quadrilateral mesh is formed between the adjacent two vertical geogrids 1.1 and the adjacent two annular geogrids 1.2, and the diameter of the inscribed circle of the mesh is not smaller than the maximum particle size of the fine stone concrete aggregate. The fine stone concrete pouring body 2 is formed by pouring fine stone concrete from the composite reinforced cage 1 into the foundation borehole, and a protective layer 2.2 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com