A microneedle-based automatic roughening device and method for basement membrane

A microneedle and basement film technology, which is applied in the field of microneedle-based automatic roughening device for basement film, can solve the problems of complex operation, limited treatment area, and difficult removal of basement film, and achieve simple device structure, high repeatability, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

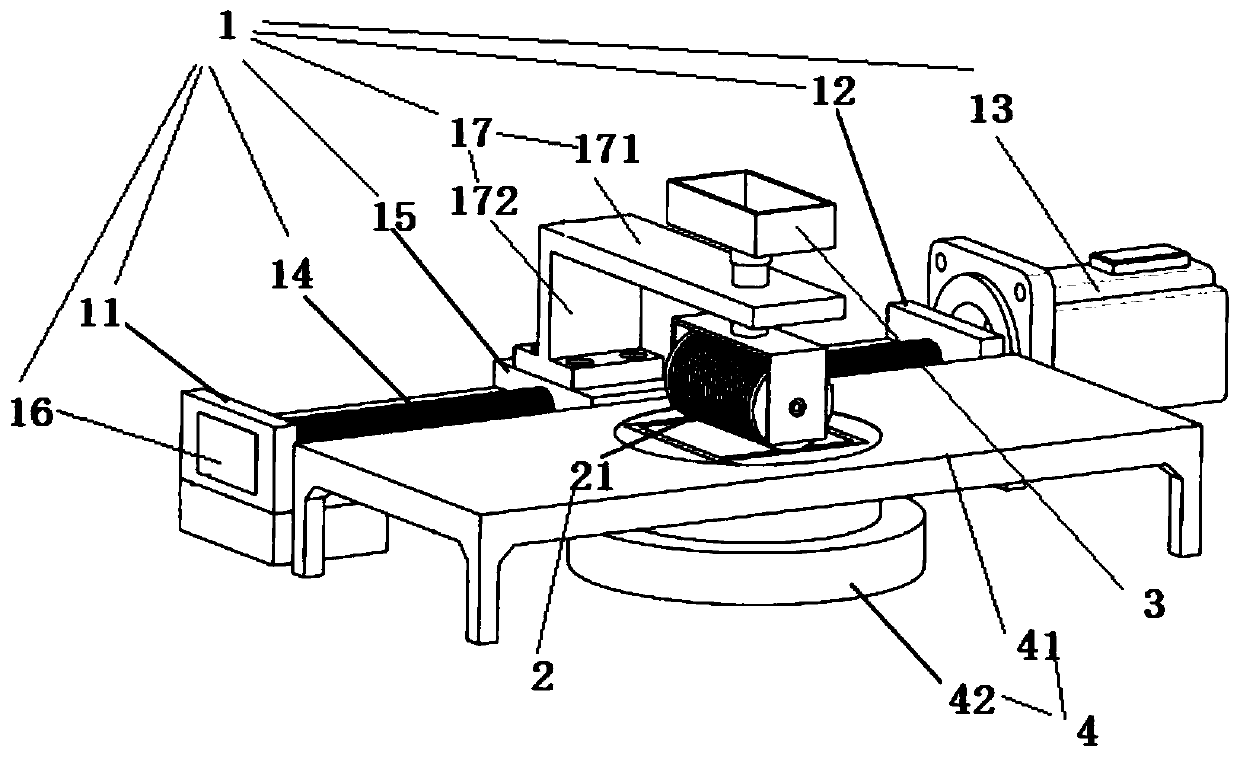

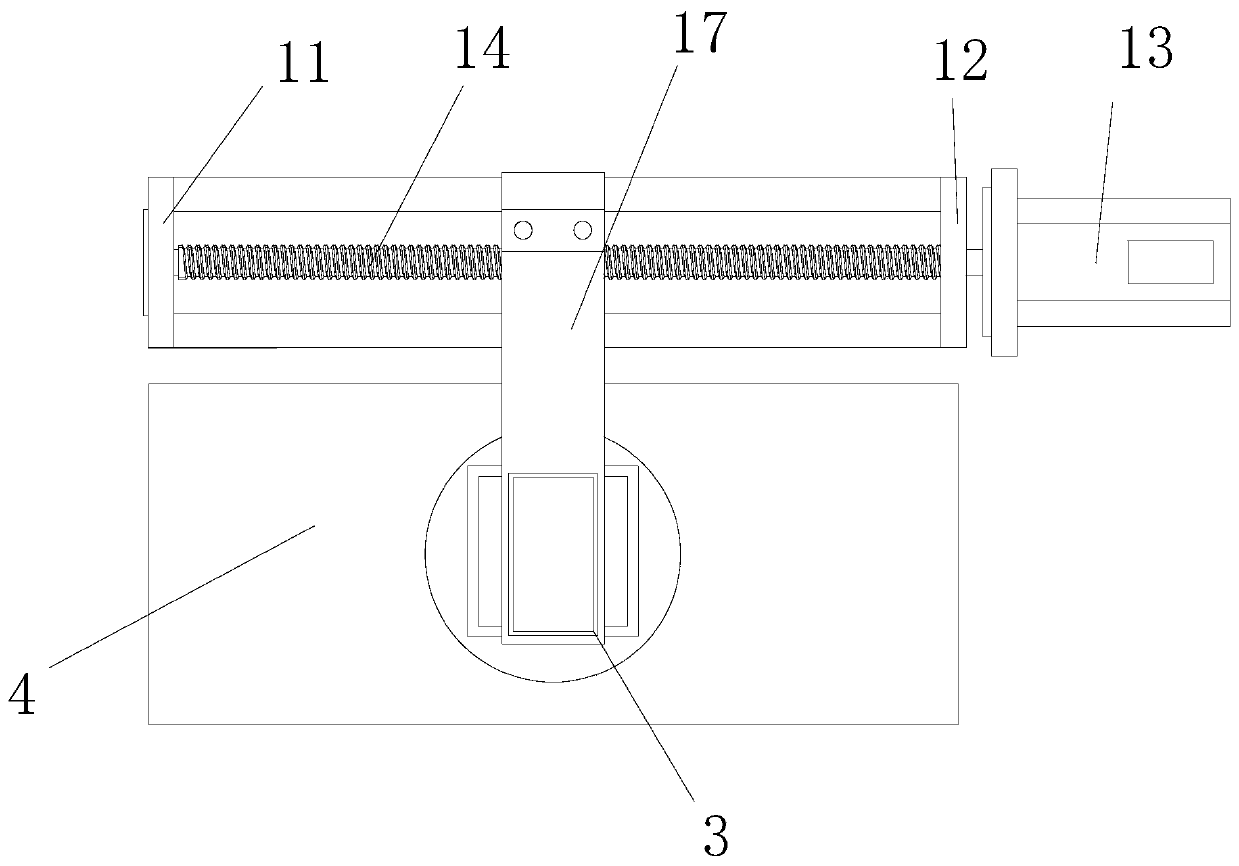

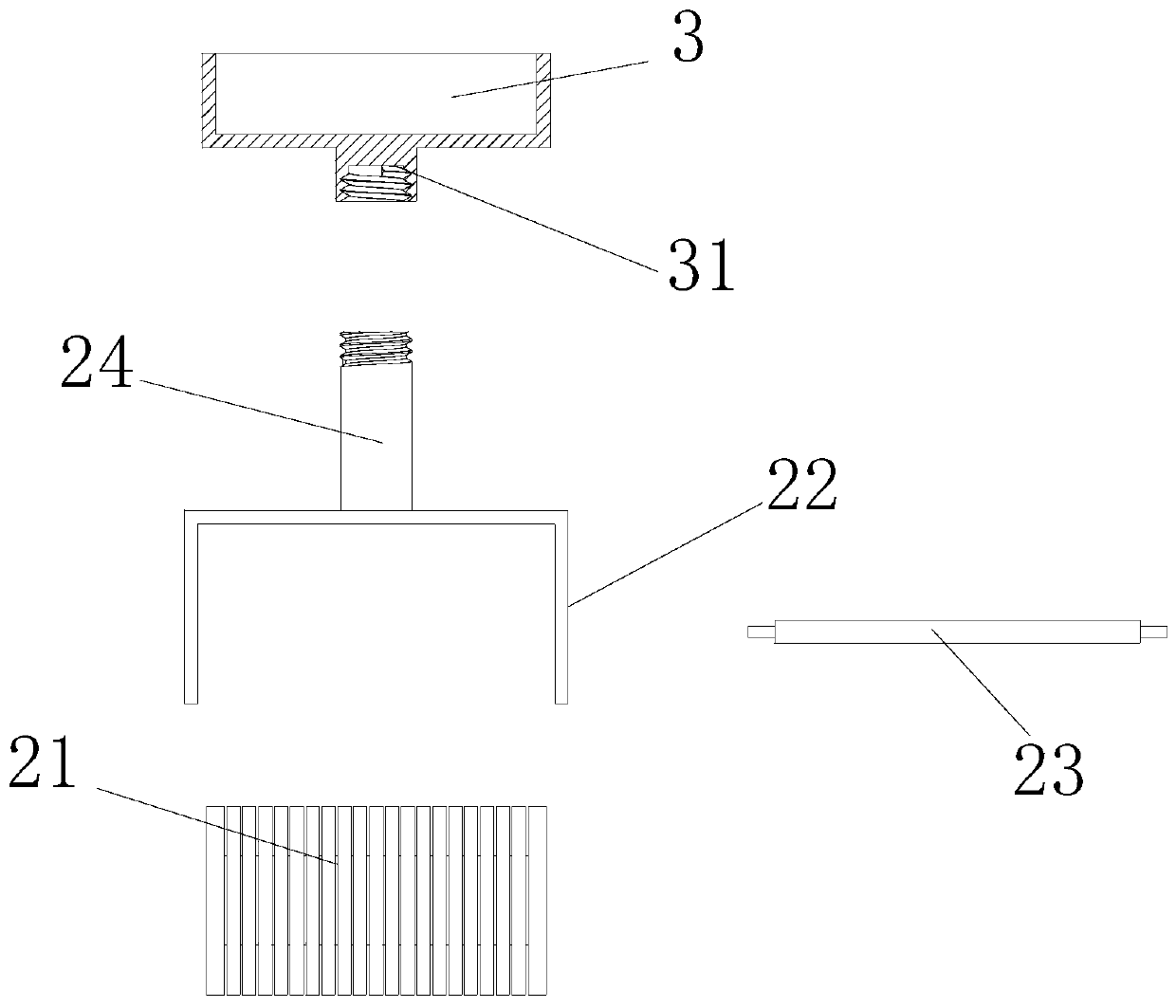

[0037] like Figure 1-2 As shown, a microneedle-based basement membrane automatic roughening device in this embodiment includes a driving part 1, a microneedle part 2, a loading platform 3, and a basement membrane fixing platform 4;

[0038] The drive unit 1 includes a drive unit and a slider 15 capable of horizontal reciprocating movement, the drive unit drives and connects the slider 15, the slider 15 is fixedly connected to the microneedle part 2, and the microneedle part 2 capable of horizontal reciprocating movement is fixed on the basement membrane. Above the platform 4, above the detachable connecting micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com