Preparation method of spherical composite oxygen carrier, product and device

An oxygen carrier and spherical technology, which is applied in the field of preparation of spherical composite oxygen carriers, can solve the problems of difficulty in meeting the needs of large-scale installations in large quantities, and achieve the effects of uniform speed control, uniform drying, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

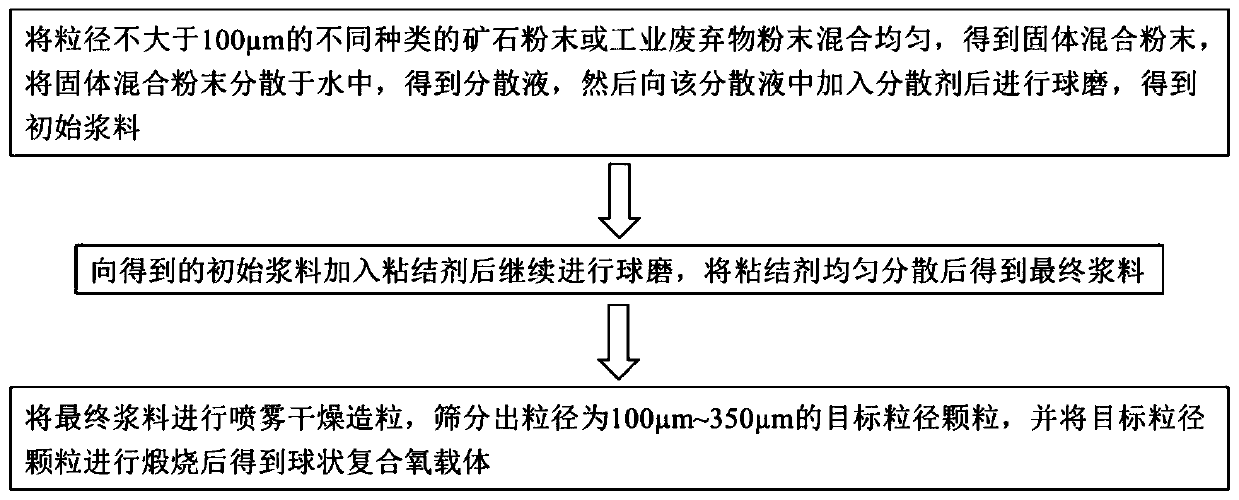

[0044] Such as figure 1 As shown, the industrial batch preparation method of cheap spherical composite oxygen carriers using ore or industrial waste as raw materials in the present invention is beneficial to realize the industrial production of oxygen carriers by combining the industrially mature spray drying technology. A preparation method of a spherical composite oxygen carrier of the present invention specifically comprises the following steps:

[0045] Step 1: Mix different types of ore powders or industrial waste powders and disperse them in water, then add a dispersant and transfer them to a ball mill for ball milling to obtain an initial slurry. The particle diameters of the ore powder and the industrial waste powder are both less than 100 μm.

[0046] Specifically, in Step 1, the particle size of the ore powder and the industrial waste powder are both less than 100 μm, and both are substances that can be used as oxygen carriers for chemical looping combustion, wherei...

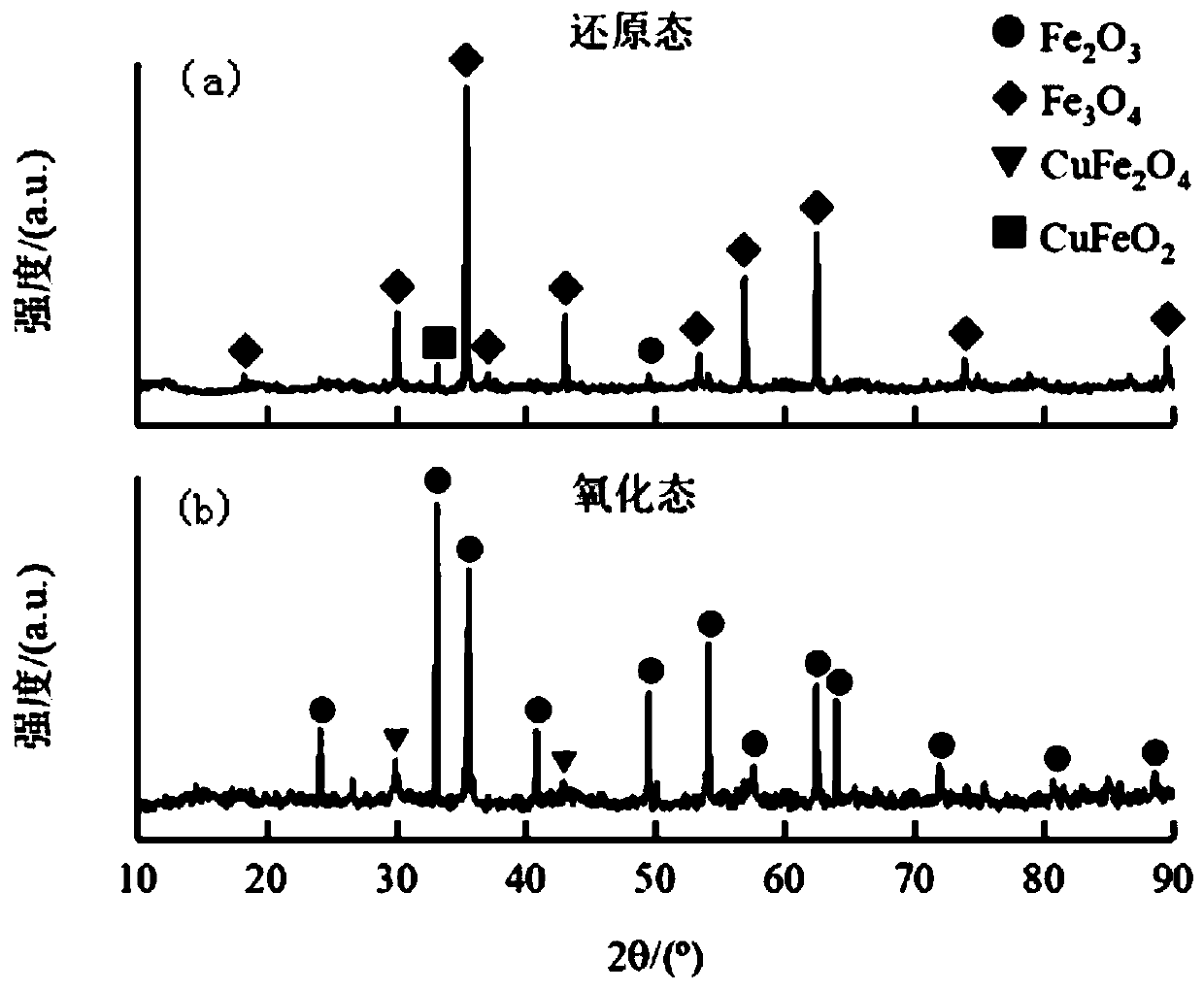

Embodiment 1

[0063] (1) 374g of red mud powder and 46g of copper ore powder are added to 200ml of water, and after adding 1.0wt% ammonium citrate dispersant to the water, the slurry is transferred to a ball mill for ball milling. The ball mill speed is 120r / min. Time is 1h, obtains initial slurry;

[0064] (2) Add 1.0wt% binder polyvinyl alcohol to the initial slurry obtained in step (1), continue ball milling for 10 minutes, and the ball milling speed is 120r / min to obtain the final slurry;

[0065] (3) The air inlet temperature of the spray dryer is set to be 185° C., and the slurry obtained in step (2) is pumped into the drying chamber by a peristaltic pump at a speed of 60 r / min. After the spray drying process is completed, it is obtained in the collection bucket. Spherical oxygen carrier particles;

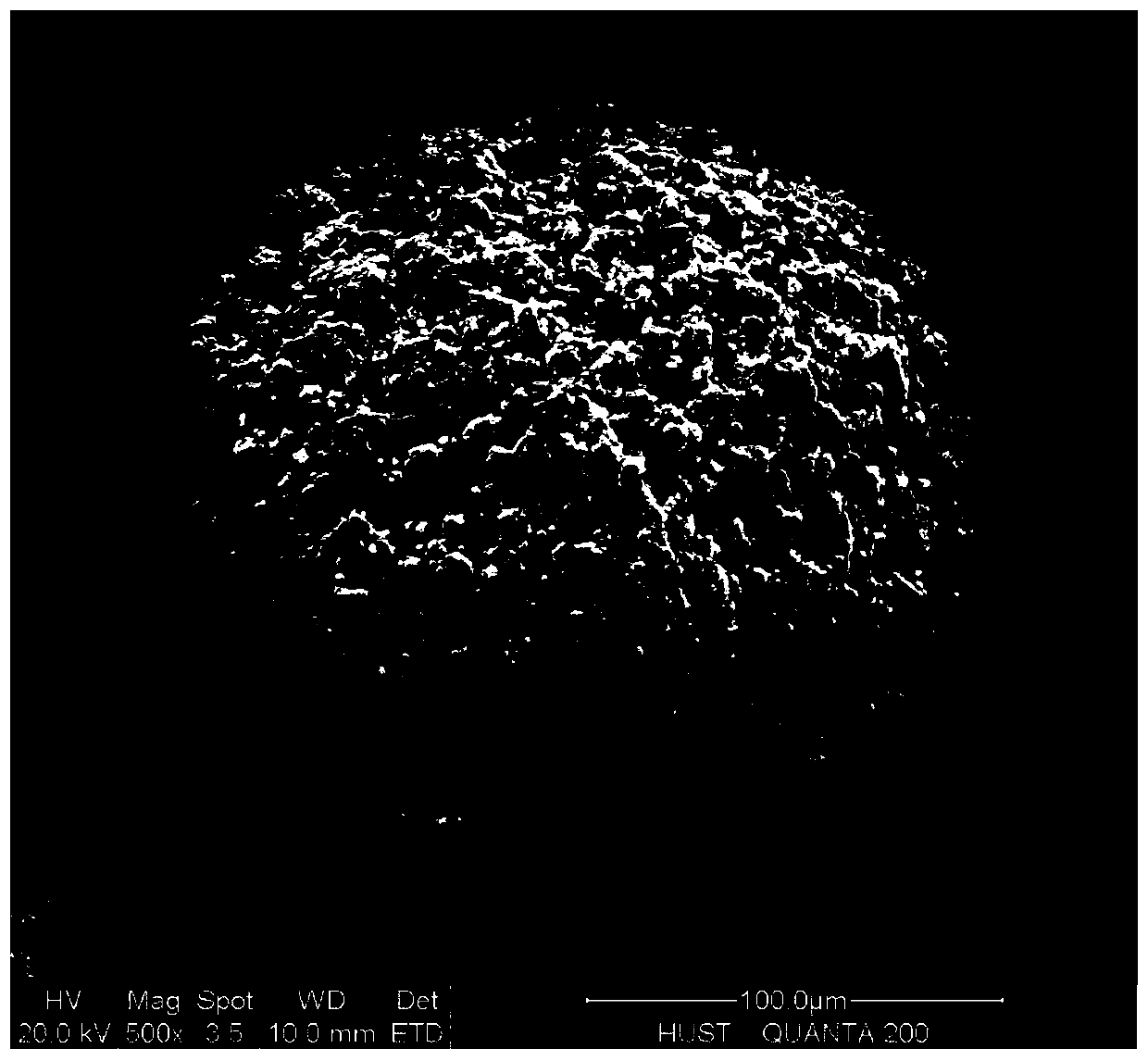

[0066] (4) Take out the spherical oxygen carrier particles, sieve to obtain oxygen carrier particles with a particle size of 100 μm-350 μm, and calcinate at 1200° C. in an air atmosphere...

Embodiment 2

[0069] (1) 338 red mud powder and 42g copper ore powder are added in 200ml water, after adding the ammonium citrate dispersant of 1.0wt% in water, slurry is transferred to row ball mill and carry out ball mill, and the speed of ball mill is 120r / min, The ball milling time is 5h to obtain the initial slurry;

[0070] (2) Add 1.6wt% binder polyvinyl alcohol to the initial slurry obtained in step (1), continue ball milling for 20 minutes, and the ball milling speed is 120r / min to obtain the final slurry;

[0071] (3) The air inlet temperature of the spray dryer is set to be 205° C., and the slurry obtained in step (2) is pumped into the drying chamber by a peristaltic pump at a speed of 55 r / min. After the spray drying process is completed, it is obtained in the collection bucket. Spherical oxygen carrier particles;

[0072] (4) Take out the spherical oxygen carrier particles, sieve to obtain oxygen carrier particles with a particle size of 100 μm-350 μm, and calcinate at 1150° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com