Movable ship-shore material resource conveying device

A conveying device, mobile technology, applied in conveyors, conveyor objects, loading/unloading, etc., can solve problems such as hidden safety hazards, adjust the docking position of ships, etc., to achieve high reliability, strong adaptability, easy to operate and easy to learn. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

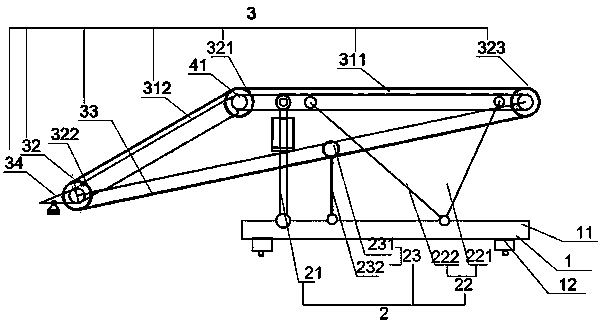

[0036]A movable ship-to-shore material transfer device includes a chassis device 1, a support adjustment mechanism 2, a conveyor belt frame device 3, and a drive and electrical control system. Chassis device 1 comprises chassis body 11, and dock traveling wheel 12 is installed on the bottom of chassis body 11, realizes the walking movement and position adjustment of conveying device along the vertical direction of conveyor belt frame on the dock. Wharf traveling wheel 12 is equipped with when loading and unloading goods, fixed transmission device position is provided with braking device.

[0037] The support adjustment mechanism 2 includes a support rod 21 for adjusting the angle of the conveying device, a fixed arm support rod 22 and a tension wheel assembly 23 . The support rod 21 is a hydraulic support rod, one end of which is hinged on the chassis body 11, and the other end is hinged on the conveyor belt frame device 3. During use, the telescopic length of the hydraulic cy...

Embodiment 2

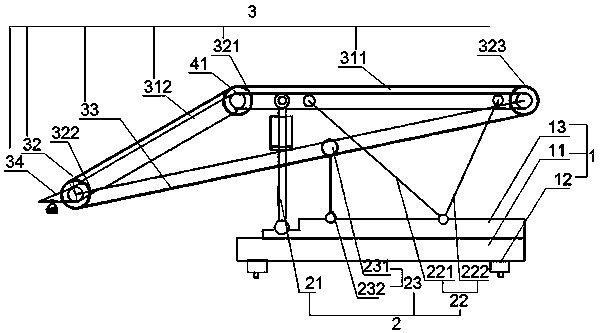

[0044] Different from Embodiment 1, in this embodiment, there is a longitudinal adjustment disc 13 on the chassis device, and the longitudinal adjustment disc 13 is used for position adjustment of the conveying device.

[0045] A movable ship-to-shore material transfer device includes a chassis device 1, a support adjustment mechanism 2, a conveyor belt frame device 3, and a drive and electrical control system. Chassis device 1 comprises chassis body 11, and dock traveling wheel 12 is installed on the bottom of chassis body 11, realizes the walking movement and position adjustment of conveying device along the vertical direction of conveyor belt frame on the dock. Wharf traveling wheel 12 is equipped with when loading and unloading goods, fixed transmission device position is provided with braking device. A longitudinal adjustment plate 13 is arranged above the chassis body 11, and the longitudinal adjustment plate 13 moves along the parallel direction of the conveyor frame 31...

Embodiment 3

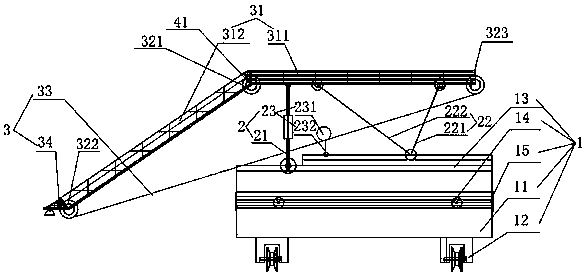

[0052] The difference between this embodiment and Embodiments 1 and 2 is that the chassis device 1 in this embodiment can adopt the chassis device in Embodiment 1 or Embodiment 2, but in this embodiment, the first driven wheel in the belt frame device 3 Can become driving wheel, then drive by external motor, original driving motor 41 is only used for adjusting the working angle of belt frame extension.

[0053] Therefore, in the description of this embodiment, only the belt rack device 3 will be described emphatically.

[0054] A movable ship-to-shore material transfer device includes a chassis device 1, a support adjustment mechanism 2, a conveyor belt frame device 3, and a drive and electrical control system. Embodiments 1 and 2 of detailed structural parts of chassis device 1, support adjustment mechanism 2, drive and electrical control system.

[0055] The conveyor belt frame device comprises a conveyor belt frame 31, a transmission wheel 32 installed on the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com