Alcohol crane pipe automatic car loading system

A crane tube and alcohol technology, applied in the field of alcohol crane tube automatic loading system, can solve the problems of unfavorable human health and safety operation, slow loading process and difficulty, and achieve the convenience of remote control and management and reduce labor intensity. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the specific embodiments of the present invention are only for the purpose of describing the technical solution more clearly, but not as a limitation of the protection scope of the present invention.

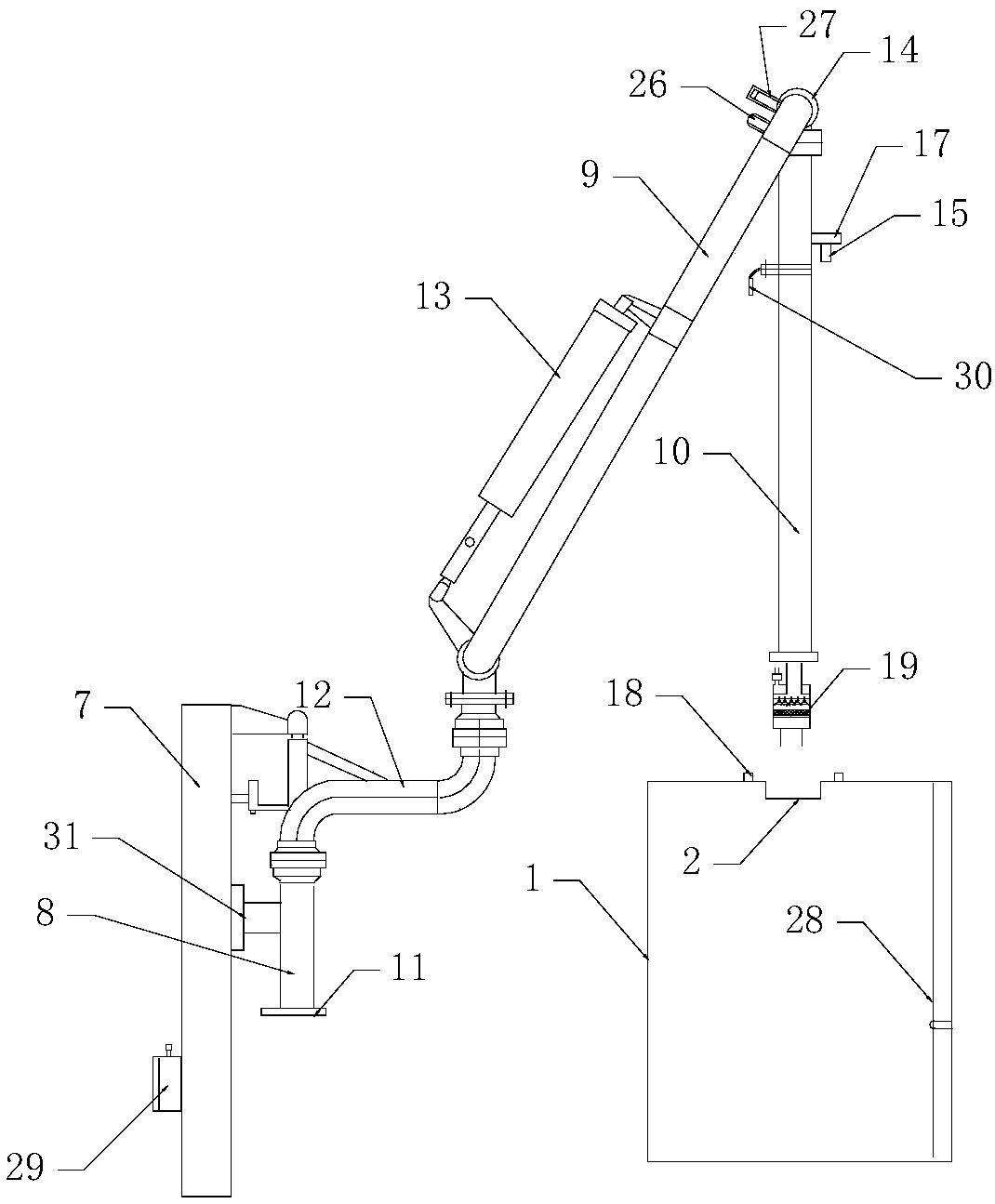

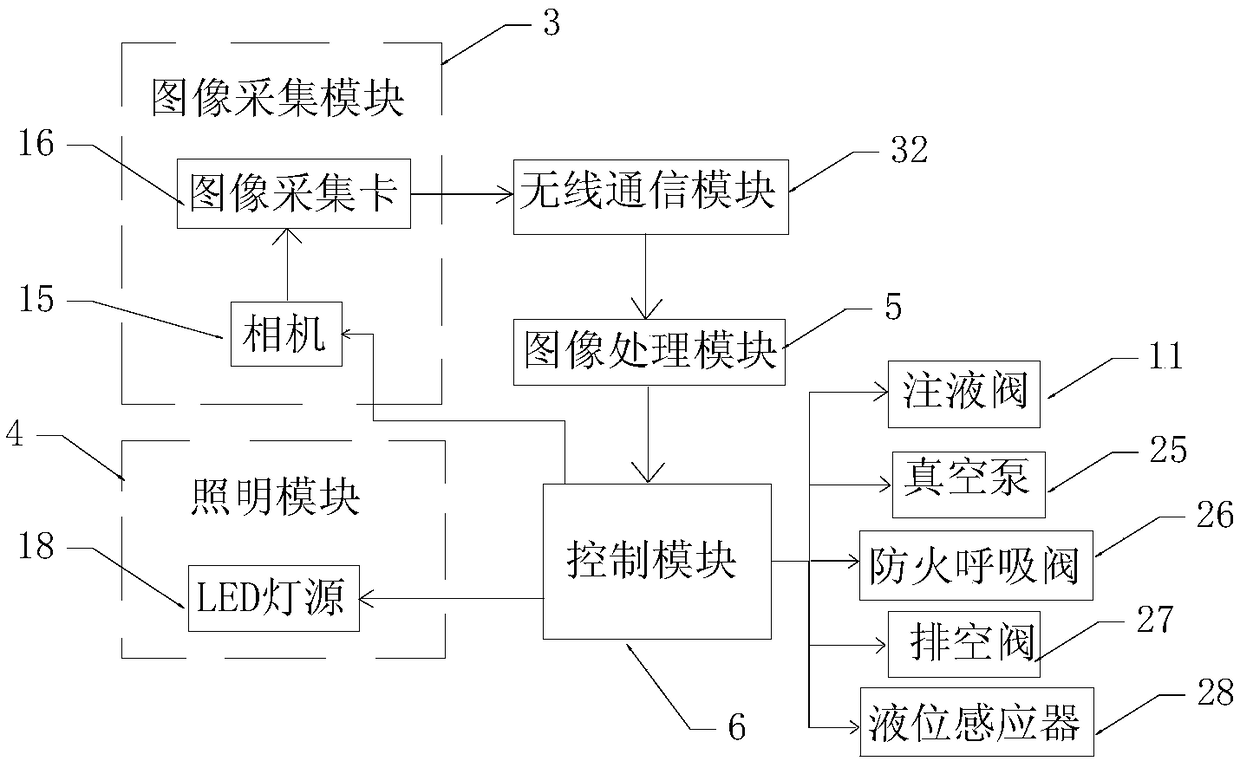

[0027] An automatic loading system for alcohol crane tubes, including a crane tube for transporting alcohol and a tank car 1 for loading alcohol; tank car 1 is provided with a tank mouth 2; it also includes an image acquisition module 3, a lighting module 4, an image Processing module 5 and control module 6;

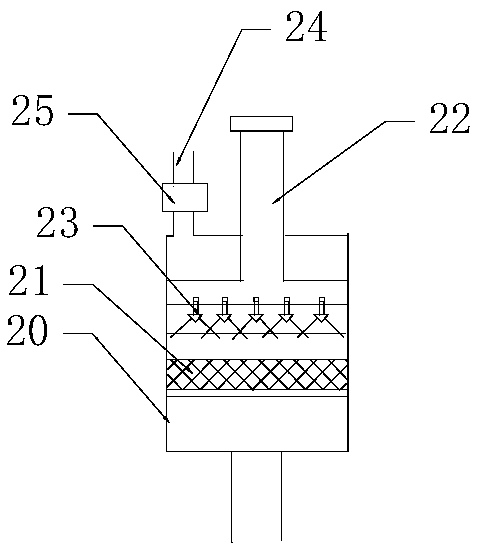

[0028] The crane tube includes a column 7, an inner arm 8, an outer arm 9 and a vertical arm 10; the column 7 is vertically set on the ground, the inner arm 8 is rotated on one side of the column 7, and the inner arm 8 is locked by the inner arm set on the column 7 31 controls. The lower end of the inner arm 8 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com