BZO glass and preparation method, as well as QLED device and manufacturing method

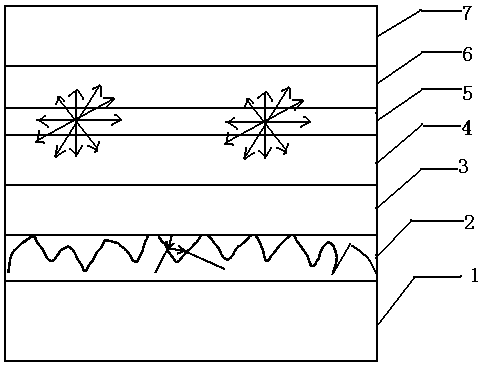

A glass and device technology, which is applied in the field of BZO glass and its preparation, QLED devices and its preparation, can solve the problems of short circuit, lower photoelectric performance of QLED devices, and poor uniformity of film thickness, etc., so as to improve uniformity, reduce trapping centers, and reduce defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A glass substrate with an area of 1.1m×1.3m×3mm is used, and an aqueous cleaning agent is added to spray the upper and lower surfaces of the glass. After scrubbing with a brush, enter the high-pressure spray ultrapure water to rinse the residual liquid on the glass surface, and finally pass through an 80°C wind Dry it in the knife chamber and send it to the LPCVD process.

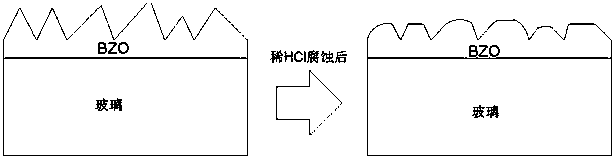

[0063] The cleaned glass is rapidly heated to 155°C in the heating chamber and sent to the LPCVD reaction chamber, and the process pressure is adjusted to 5×10 -3 mbar, H 2 O / DEZ flow ratio is 1.1, DEZ / B 2 h 6 Flow ratio is 3, DEZ flow is 480sccm, H 2 O flow 528sccm, B 2 h 6 The flow rate is 160sccm, and the deposition time is 300s. The thickness of the BZO film is 1820nm, the sheet resistance is about 16Ω / □, and the haze is 25%. After the deposition is completed, it is sent to be corroded with a dilute HCl solution. The volume concentration of the dilute HCl solution is 0.5%, the solution t...

Embodiment 2

[0065] A glass substrate with an area of 1.1m×1.3m×3mm is used, and an aqueous cleaning agent is added to spray the upper and lower surfaces of the glass. After scrubbing with a brush, enter the high-pressure spray ultrapure water to rinse the residual liquid on the glass surface, and finally pass through an 80°C wind Dry it in the knife chamber and send it to the LPCVD process.

[0066] The cleaned glass is rapidly heated to 155°C in the heating chamber and sent to the LPCVD reaction chamber, and the process pressure is adjusted to 5×10 -3 mbar, H 2 O / DEZ flow ratio is 1.1, DEZ / B 2 h 6 Flow ratio is 3, DEZ flow is 480sccm, H 2 O flow 528sccm, B 2 h 6 The flow rate is 160sccm, and the deposition time is 300s. The thickness of the BZO film is 1820nm, the sheet resistance is about 16Ω / □, and the haze is 25%. After the deposition is completed, it is sent to be corroded with a dilute HCl solution. The volume concentration of the dilute HCl solution is 2%, the solution tem...

Embodiment 3

[0068] A glass substrate with an area of 1.1m×1.3m×3mm is used, and an aqueous cleaning agent is added to spray the upper and lower surfaces of the glass. After scrubbing with a brush, enter the high-pressure spray ultrapure water to rinse the residual liquid on the glass surface, and finally pass through an 80°C wind Dry it in the knife chamber and send it to the LPCVD process.

[0069] The cleaned glass is rapidly heated to 155°C in the heating chamber and sent to the LPCVD reaction chamber, and the process pressure is adjusted to 5×10 -3 mbar, H 2 O / DEZ flow ratio is 1.1, DEZ / B 2 h 6 Flow ratio is 3, DEZ flow is 480sccm, H 2 O flow 528sccm, B 2 h 6 The flow rate is 160sccm, and the deposition time is 300s. The thickness of the BZO film is 1820nm, the sheet resistance is about 16Ω / □, and the haze is 25%. After the deposition is completed, it is sent to be corroded with a dilute HCl solution. The volume concentration of the dilute HCl solution is 5%, the solution tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com