Tea wine and brewing process thereof

A technology for tea wine and tea leaves, applied in the field of tea wine and its brewing process, can solve the problems of difficult decomposition and extraction of nutrients in tea leaves, residue of tea slag, excess fusel oil, etc. Sensation, the effect of accelerating maturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

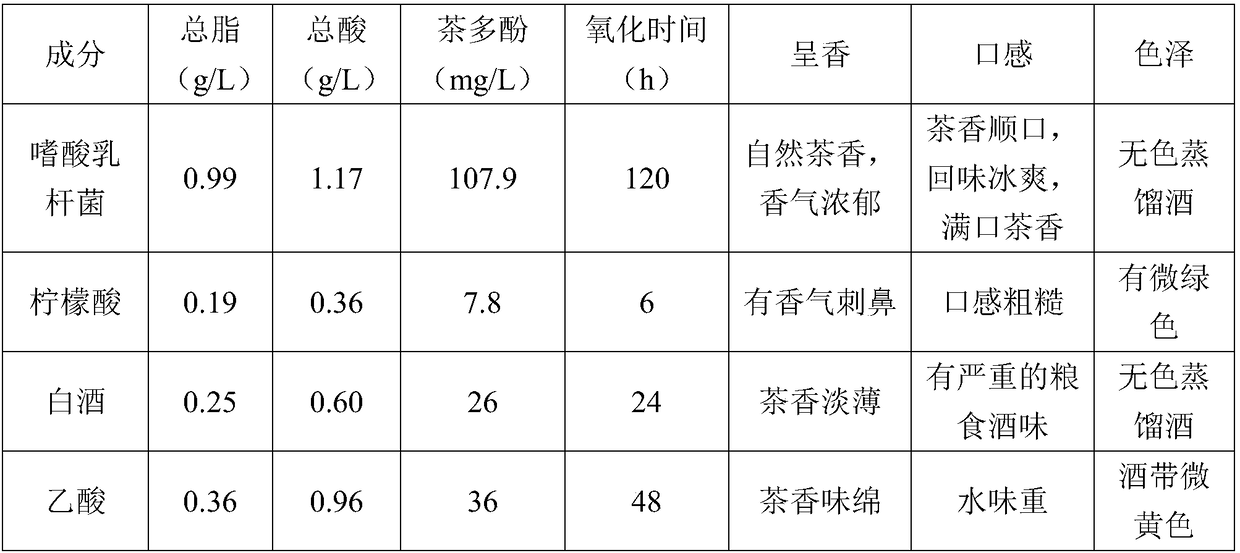

Image

Examples

Embodiment 1

[0021] 15-30 parts of tea leaves, 150-200 parts of barley, 0.04-0.06 parts of cellulase, 0.04-0.1 parts of Lactobacillus acidophilus, 0.2-0.5 parts of distiller's yeast, and the balance is water.

[0022] The composition of tea wine is: 20 parts of tea leaves, 160 parts of barley, 0.04 parts of cellulase, 0.04 parts of Lactobacillus acidophilus, 1.2 parts of distiller's yeast, and the balance is water.

[0023] Prepared according to the following steps:

[0024] 1) Make tea: put 20kg of aged tea into a stainless steel bucket, add 80kg of 46°C water, and moisten for 40 minutes, add 0.6g of Lactobacillus acidophilus to the tea liquid to adjust the pH value to 4.8 dealkalized tea mixture; Add cellulase at 40°C and let stand for 24 hours to obtain tea mixture for later use

[0025] 2) Pre-fermentation: Steam 160kg of barley, add 1.2kg of distiller’s yeast, saccharify the lower koji to obtain wort, add the wort to the tea mixture at a mass ratio of 1:1, and ferment for 3 days at a...

Embodiment 2

[0031] The composition of tea wine is: 15 parts of tea leaves, 160 parts of barley, 0.04 parts of cellulase, 0.04 parts of Lactobacillus acidophilus, 1.2 parts of distiller's yeast, and the balance is water.

[0032] Prepared according to the following steps:

[0033] 1) Making tea: Put 15kg of green tea into a stainless steel bucket, add 60kg of 46°C water, and moisten for 40 minutes, add 0.6g of Lactobacillus acidophilus into the tea liquid to adjust the pH value to 4.8 dealkalized tea mixture; Add cellulase at 40°C and let stand for 24 hours to obtain tea mixture for later use

[0034] 2) Pre-fermentation: Steam 150kg of barley, add 1kg of Angel compound distiller's koji, saccharify the lower koji to obtain wort, add the wort to the tea mixture at a mass ratio of 1:1, and ferment for 3 days at a temperature of 32 ℃, to obtain the mother fermentation broth;

[0035] 3) Post-fermentation: adjust the fermentation temperature of the mother's fermentation liquid to 28°C, add 3...

Embodiment 3

[0040] The composition of the tea wine is: 30 parts of tea leaves, 200 parts of barley, 0.06 parts of cellulase, 0.1 part of Lactobacillus acidophilus, 2 parts of distiller's yeast, and the balance is water.

[0041] Prepared according to the following steps:

[0042] 1) Make tea: put 30kg of black tea into a stainless steel barrel, add 120kg of water at 46°C, lubricate for 40 minutes, add 0.8g of Lactobacillus acidophilus to the tea liquid to adjust the pH value to 4.8 dealkalized tea mixture; Add cellulase at 40°C and let stand for 24 hours to obtain tea mixture for later use

[0043] 2) Pre-fermentation: Steam 200kg of barley, add 2kg of Angel compound distiller's koji, saccharify the lower koji to obtain wort, add the wort to the tea mixture at a mass ratio of 1:1, and ferment for 3 days at a temperature of 32 ℃, to obtain the mother fermentation broth;

[0044] 3) Post-fermentation: adjust the fermentation temperature of the mother's fermentation liquid to 28°C, add 4 / 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com