Preparation method for gallium doped polycrystalline silicon ingot and gallium doped polycrystalline silicon ingot

A technology of polycrystalline silicon ingots and polycrystalline silicon, which is applied in the preparation of gallium-doped polycrystalline silicon ingots and in the field of gallium-doped polycrystalline silicon ingots, which can solve the problems of uneven distribution of doping concentration and achieve uniform doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

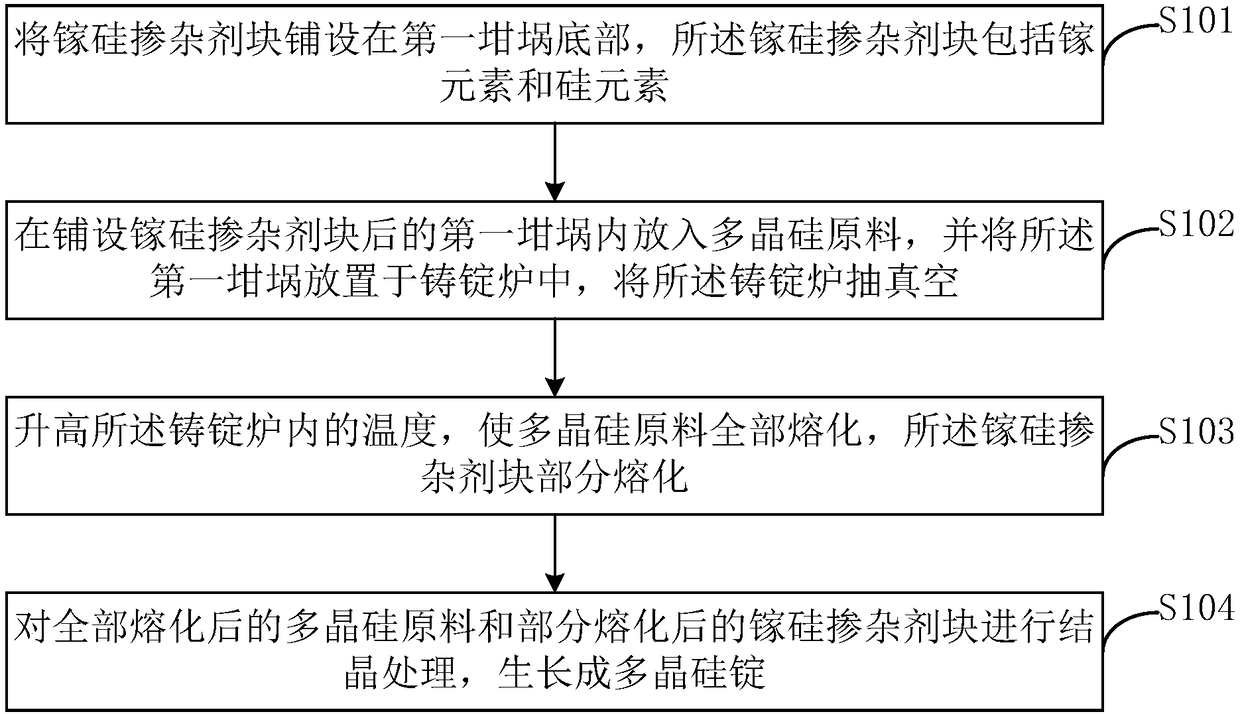

[0042] Please refer to figure 1 , the preparation method of gallium-doped polycrystalline silicon ingot comprises:

[0043] Step S101 , laying a gallium-silicon dopant block on the bottom of the first crucible, the gallium-silicon dopant block including gallium element and silicon element.

[0044] In the embodiment of the present invention, a plurality of SiGa dopant blocks are spread on the bottom of the first crucible so that the SiGa dopant blocks just cover the bottom of the crucible. The gallium silicon dopant block has a side length of 152 mm to 160 mm and a thickness of 10 mm to 20 mm. For example, if 36 gallium-silicon dopant blocks are laid flat on the bottom of a G6 crucible and placed in a single layer, the 36 gallium-silicon dopant blocks can just cover the bottom of the crucible.

[0045] Optionally, the mass ratio of silicon element to gallium element in the gallium-silicon dopant block is 100000:7 to 10000:35.

[0046] In the embodiment of the present invent...

Embodiment 2

[0072] A gallium-doped polycrystalline silicon ingot is prepared according to the preparation method of the gallium-doped polycrystalline silicon ingot described in the first aspect of the embodiment of the present invention, and has the beneficial effects of the first embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com