Method for measuring specific surface area of explosive crystals

A specific surface area and crystal technology, which is applied in the field of determining the specific surface area of explosive crystals, can solve the problem that the internal closed pores and surface open pores of explosive crystals cannot be quantified at the same time, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 measures the specific surface area of HMX explosive crystal powder

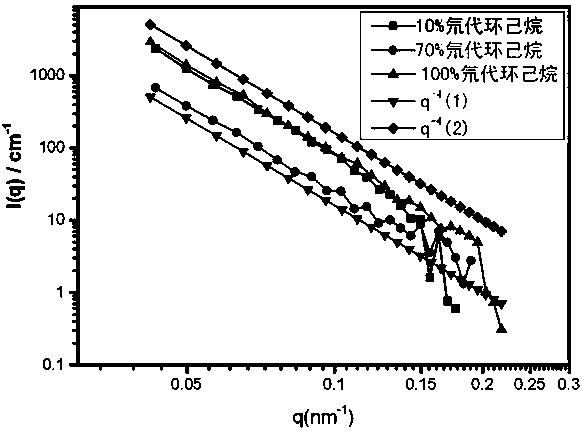

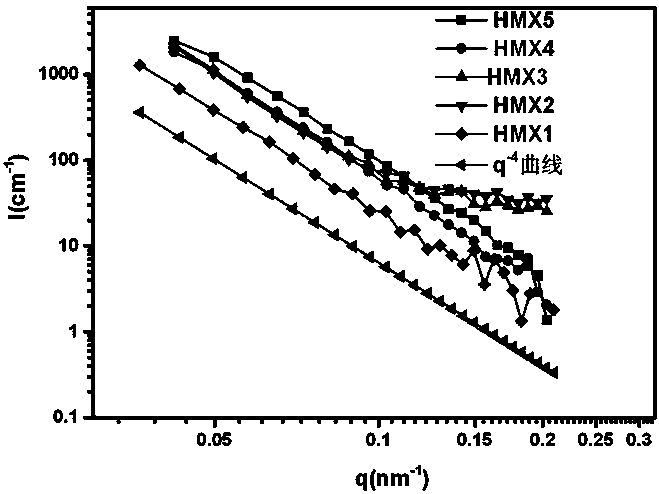

[0029] In order to measure the specific surface area of closed cells inside the HMX explosive crystal and open pores on the outer surface, cyclohexane (neutron scattering length density of neutron scattering length density is -0.279×10 10 cm -2 ) and deuterated cyclohexane (with a neutron scattering length density of 6.68×10 10 cm -2 ) as a solution for contrast soaking; deuterated cyclohexane and non-deuterated cyclohexane are prepared into three series of mixed solutions for contrast transformation according to the volume ratio of 10:90, 70:30 and 0:100; then The mixed solution and five kinds of HMX explosive crystal powders to be tested are placed together in a special-purpose quartz cuvette for neutron small-angle scattering with a neutron optical path of 1 mm and left to stand for 24 hours to obtain a series of contrast-transformed explosive crystal suspensions; then use The ne...

Embodiment 2

[0032] Embodiment 2 Determination of the specific surface area of TATB explosive crystals in a certain TATB-based PBX sample

[0033] In order to measure the specific surface area of the internal closed cells and the open pores of the outer surface of the TATB explosive crystal in a TATB-based PBX explosive, firstly select ethyl acetate to dissolve the binder in the PBX, and then filter and dry to obtain the TATB explosive crystal powder; Water insoluble in TATB explosive crystals (neutron scattering length density is -0.560×10 10 cm -2 ) and heavy water (neutron scattering length density is 6.33×10 10 cm -2 ) as a solution for contrast soaking; water and heavy water are prepared into three series of mixed solutions for contrast transformation in a volume ratio of 50:50, 21:79, and 0:100; then the mixed solution and the TATB explosive to be tested The crystal powder is placed together in a special quartz cuvette for neutron small-angle scattering with a neutron optical ...

Embodiment 3

[0034]Embodiment 3 Measure the specific surface area of a certain LLM-105 explosive crystal

[0035] Methanol that is insoluble in LLM-105 explosive crystals is selected (the neutron scattering length density is -0.373×10 10 cm -2 ) and deuterated methanol (with a neutron scattering length density of 5.80×10 10 cm -2 ) as a solution for contrast soaking; methanol and deuterated methanol are prepared into three series of mixed solutions for contrast transformation in a volume ratio of 100:0, 10:90, and 0:100; then the mixed solution and LLM- 105 explosive crystal powders were placed together in a special quartz cuvette for ultra-small-angle neutron scattering with a neutron optical path length of 20 mm and left to stand for 24 hours to obtain a series of contrast-transformed explosive crystal suspensions; small-angle neutron scattering test, and obtain experimental data; then carry out buckle and absolute intensity correction to the ultra-small-angle neutron scattering exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com