Wound type solid-state capacitor preparation method

A solid capacitor, wound-type technology, applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, capacitors, etc., can solve the problems of easy contamination of oxidant solution, risk of poor product performance, increased management difficulty, etc., to maintain product consistency, Improve the capacity extraction rate and reduce the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] In the embodiment, the preparation of the mixture solution is firstly carried out. During the preparation, 5wt% imidazole is added to the ethanol solution of toluenesulfonic acid with a solid content of 55wt% at a temperature of 20°C, and then kept warm and added with 10wt% monomer EDOT , ultrasonically oscillated, and the prepared mixture solution was placed in a refrigerator at a temperature of 10° C. for later use.

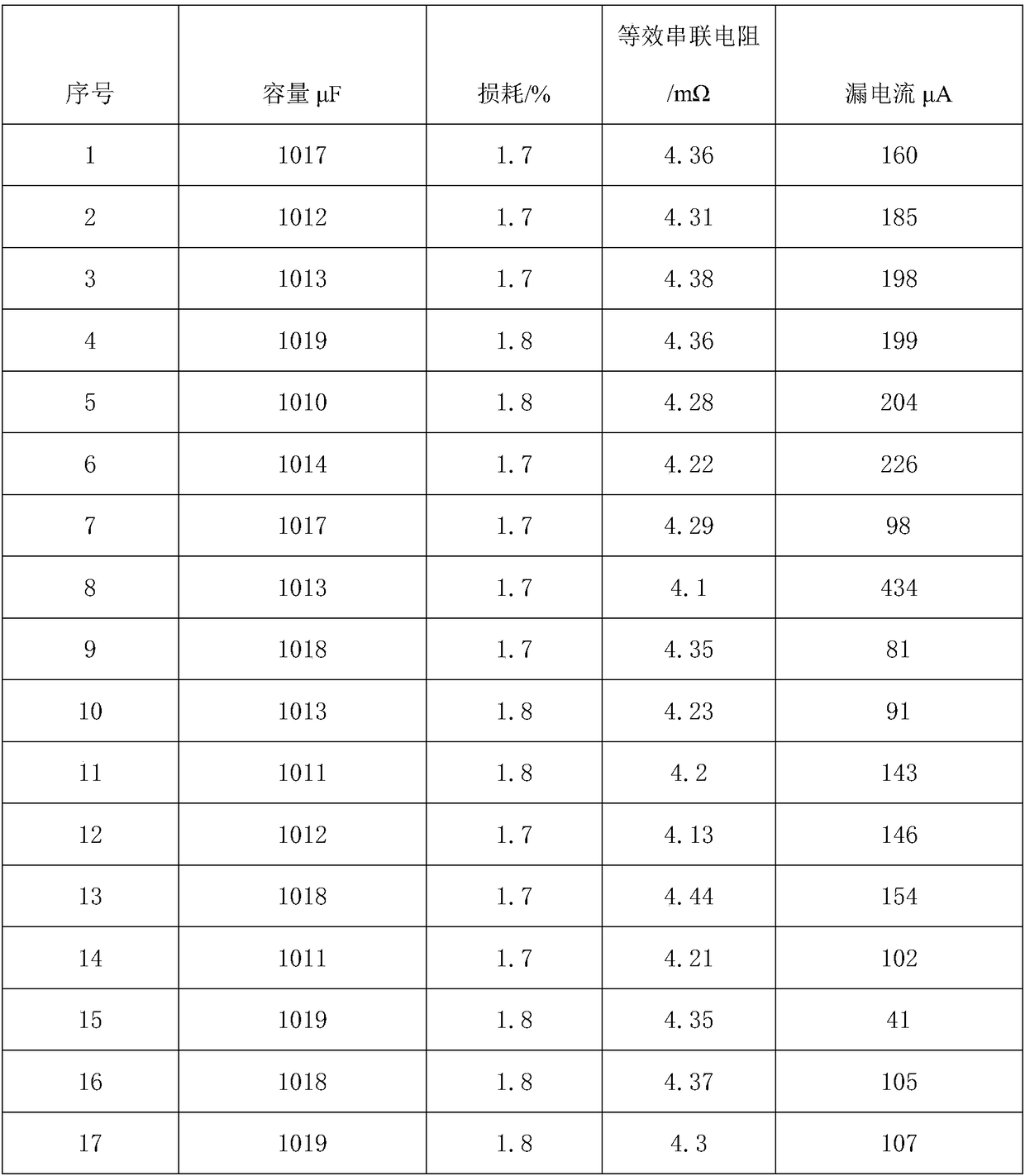

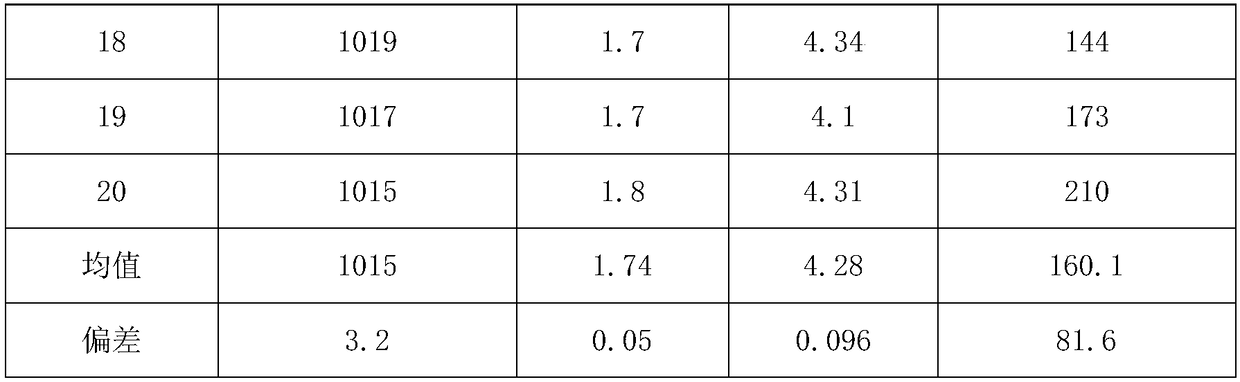

[0029] When preparing a winding solid capacitor, take the preparation of a 6.3V-1000μF solid capacitor as an example: when preparing it, first cut it, cut the anode foil, cathode foil and electrolytic paper into the width specified by the process, and then insert the positive guide pin The nail is riveted on the anode alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com