A kind of ultra-low temperature lithium-ion battery and preparation method thereof

A lithium-ion battery, ultra-low temperature technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of decreased discharge capacity, decreased discharge rate performance, and failure to use normally, so as to improve isotropy and compensate for the decrease in conductivity , The effect of reducing the diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

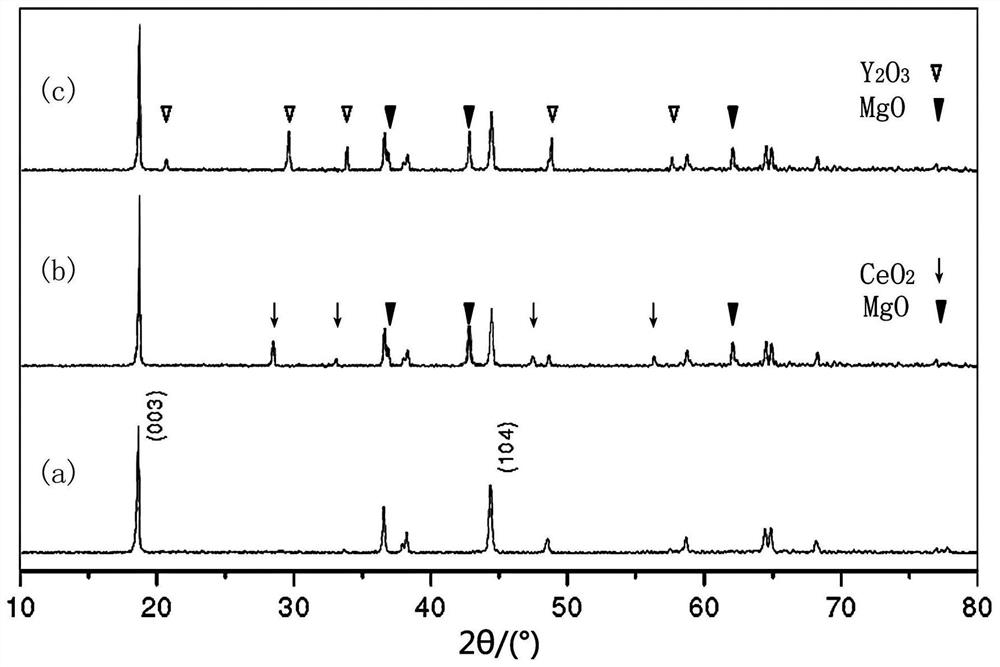

[0029] A method for preparing a positive electrode active material. First, uniformly mix rare earth metal oxides and alkaline earth metal oxides at a mass ratio of 1:1, and then add 0.05-5 parts of mixed powder to 100 parts of LiCoO 2 Among them, sinter after mixing evenly to form LiCoMO compound, which can be obtained after jet milling and classification, where M represents a mixture of rare earth elements and alkaline earth metals.

[0030] Further, the sintering conditions are sintering at a temperature of 850°C-950°C for 10h-15h in an inert gas atmosphere; the rare earth elements include one of Sc, Y, La, Ce, Nd, Gd and Sm, so The alkaline earth metals include Mg.

[0031] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

[0032] A method for preparing an ultra-low temperature lithium-ion battery, first preparing positi...

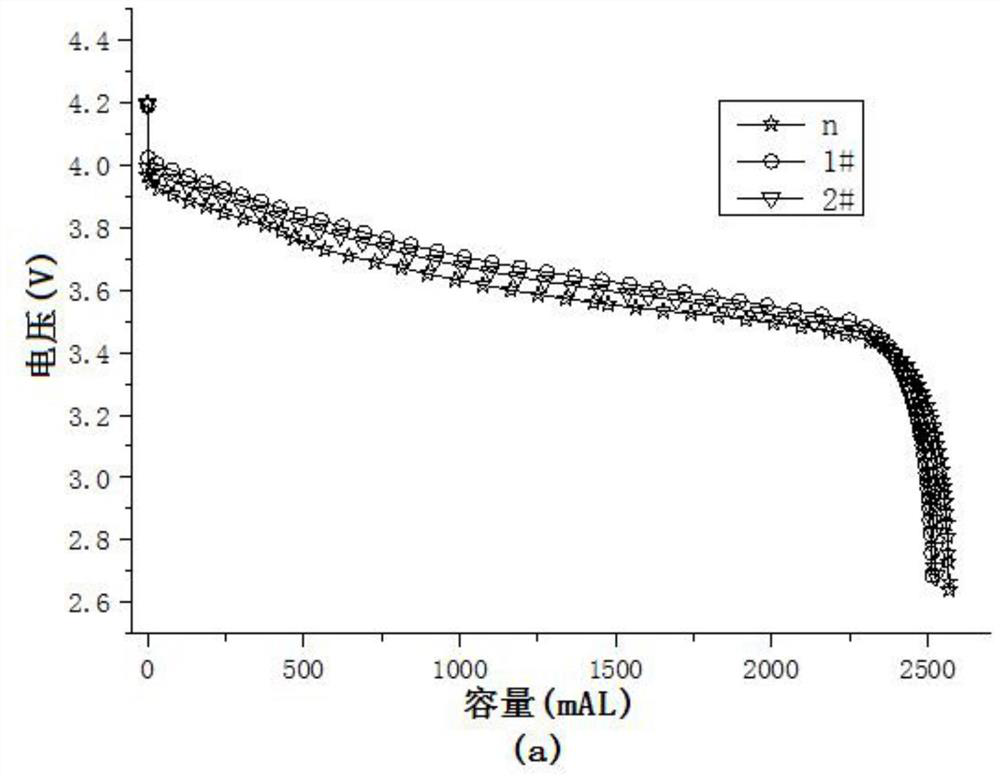

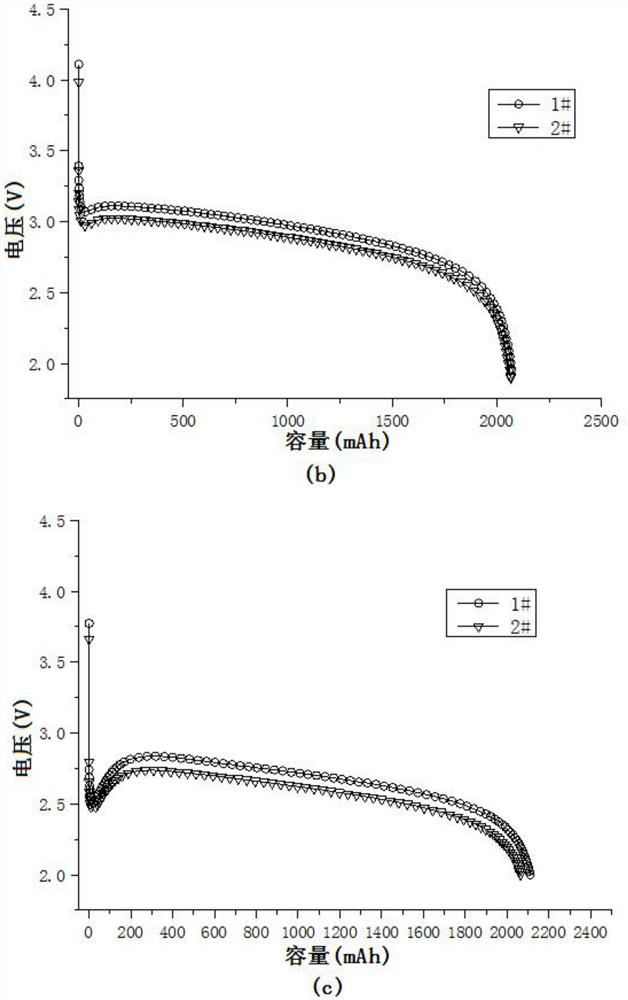

Embodiment 1

[0047] A method for preparing positive electrode active materials, firstly, CeO with a particle size of 10 μm-30 μm 2 Mix evenly with MgO at a mass ratio of 1:1, and then add 4 parts of the mixed powder to 100 parts of LiCoO 2 In, and mixed uniformly; then sintered to form a LiCoMO compound, which is obtained after jet milling and classification, where M represents a mixture of Ce and Mg.

[0048] Further, the sintering condition is sintering at a temperature of 950° C. for 10 h in an inert gas atmosphere; in this embodiment, the rare earth element is Ce, and the alkaline earth metal is Mg.

[0049] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

Embodiment 2

[0051] A method for preparing positive electrode active materials, firstly, CeO with a particle size of 10 μm-30 μm 2 and MgO in a mass ratio of 1:1, and then in parts by mass, take 2 parts of the mixed powder and add it to 100 parts of LiCoO 2 In, and mixed uniformly; then sintered to form a LiCoMO compound, which is obtained after jet milling and classification, where M represents a mixture of Ce and Mg.

[0052] Further, the sintering condition is sintering at a temperature of 900° C. for 13 hours in an inert gas atmosphere; in this embodiment, the rare earth element is Ce, and the alkaline earth metal is Mg.

[0053] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com