Microstrip antenna based on artificial magnetic conductor

A technology of artificial magnetic conductors and microstrip antennas, which is applied to the structural forms of antennas, electrical components, and radiation elements, etc., can solve the problems of microstrip antennas with complex structures, large sizes, return loss and gain effects that cannot meet technical requirements, etc. Achieve the effects of easy industrial processing, increased gain, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

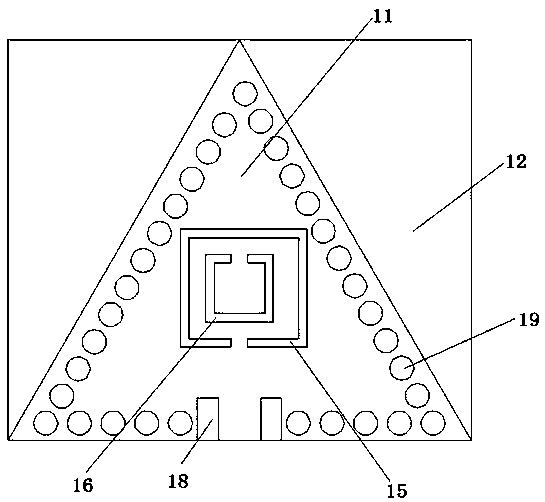

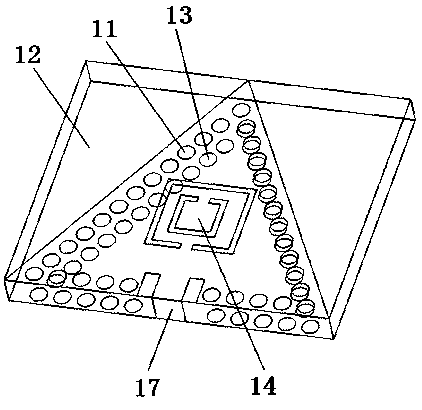

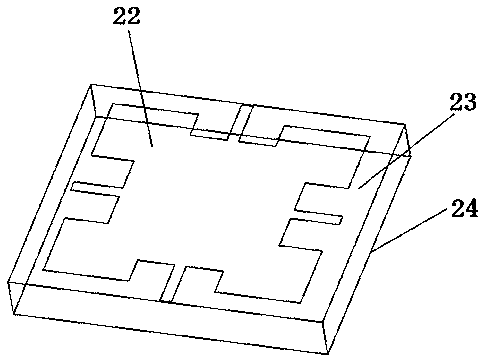

[0039] A microstrip antenna based on an artificial magnetic conductor, such as Figure 5As shown, it includes an isosceles triangular microstrip antenna and an artificial magnetic conductor reflection substrate, wherein the artificial magnetic conductor reflection unit adopts a Rogers 6010 dielectric substrate with a dielectric constant of 10.2 and a thickness of 1.0mm. Image 6 It is the S parameter simulation waveform diagram of this embodiment, as can be seen from the figure, the center frequency of this embodiment is 12.3GHz, the return loss is greater than 12dB, the antenna gain is 4.9dB, and the working performance is good; Figure 8 It is the 3D radiation pattern of this embodiment, indicating the spatial distribution of the electric field, the color depth represents the radiation intensity, the darker the color, the stronger the electric field, and the lighter the color, the weaker the electric field).

Embodiment 2

[0041] A microstrip antenna based on an artificial magnetic conductor, such as Figure 5 As shown, the artificial magnetic conductor reflection unit adopts a Rogers 5880 dielectric substrate with a dielectric constant of 2.2 and a thickness of 1.0mm. Figure 7 It is the S-parameter simulation waveform diagram of this embodiment, as can be seen from the figure, the center frequency is 12.3GHz, the return loss is greater than 14dB, the antenna gain is 7.8dB, and the working performance is good; Figure 9 is the 3D radiation pattern of this example, compared to Figure 8 , the radiation direction of this embodiment is changed from bidirectional to unidirectional, the gain is increased by nearly 3dB, the directivity becomes better, and the high gain of the antenna is realized.

[0042] In the present invention, a triangular microstrip antenna with high radiation rate and an artificial magnetic conductor reflective substrate with the same phase reflection characteristics are combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com