Transition metal chalcogenide nanowire and preparation method and application thereof

A technology of transition metal chalcogenides and transition metals, applied in the field of materials, can solve the problems of irregular shape of nanowires, low efficiency of nanowire preparation, complicated operation, etc., achieve regular shape, overcome difficult control of nanowire width, and overcome difficult control The effect of irradiated energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare Mo in the embodiment of the present application 6 Se 6 The method of nanowires adopts molecular beam epitaxy, and the preparation method is mainly divided into three steps:

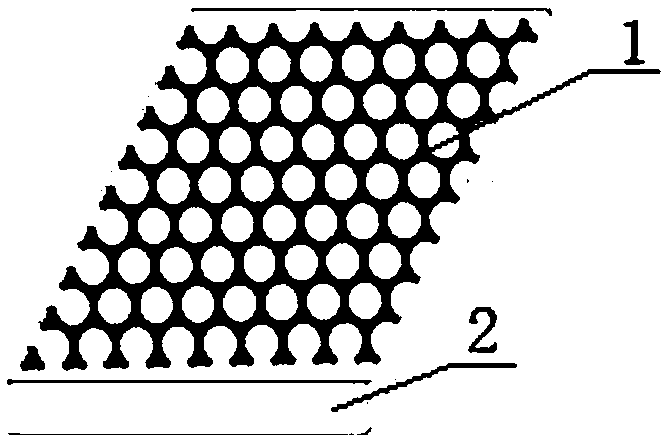

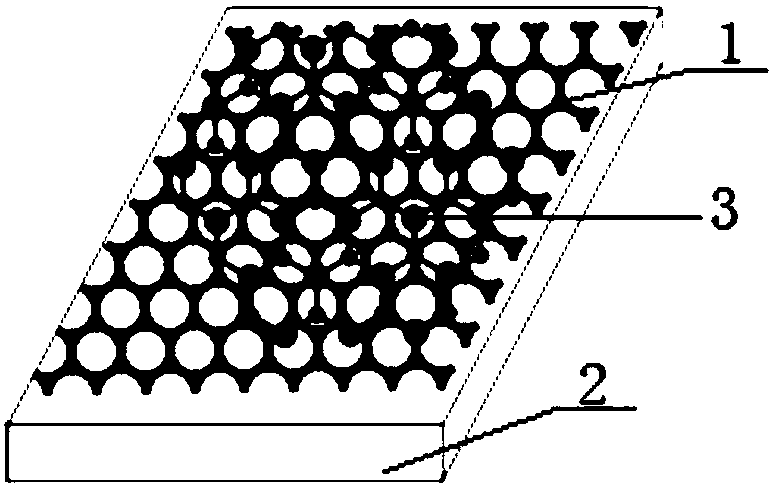

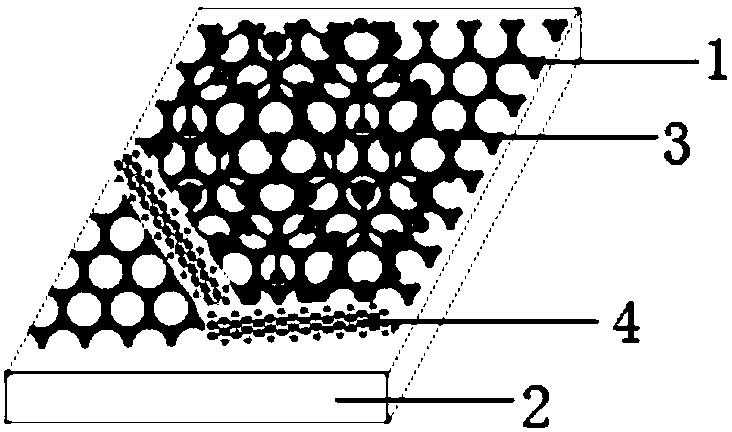

[0032] (1) Preparation of large-area graphene. Purchase a commercial SiC substrate from MTI, and maintain the SiC sample at 600°C for nearly 3 hours to remove impurity atoms adsorbed on the surface. Under the atmosphere of Si atomic flow, the temperature of SiC was raised to 950°C and maintained for 2 minutes, and then the substrate temperature was lowered to 600°C. Repeat for 5 cycles. Finally, in an atmosphere without Si atom flow, the substrate temperature was further increased to 1350 °C and maintained for 5 minutes to remove Si atoms adsorbed on the surface. Repeat this step 3 times. In the end, we will obtain large-area layered graphene, which is characterized by scanning tunneling microscopy, and the surface topography is shown in Figure 2. Figure 2(a) is a topography image of ...

Embodiment 2

[0036] By controlling the annealing time, Mo can be regulated 6 Se 6 The formation ratio of nanowires on the boundary. The method for preparing transition metal chalcogenide nanowires in this example is the same as Example 1, except that MoSe 2 The annealing time of the film was set to 1.75 hours, and the morphology of transition metal chalcogenide nanowires obtained is shown in Figure 5(a). The size of Figure 5(a) is 100nm×100nm, and the scanning conditions are 3V, 4pA. It can be seen from Figure 5(a) that a part of MoSe 2 Mo 6 Se 6 Nanowires.

Embodiment 3

[0038] By controlling the annealing time, Mo can be regulated 6 Se 6 The formation ratio of nanowires on the boundary. The method for preparing transition metal chalcogenide nanowires in this example is the same as Example 1, except that MoSe 2 The film annealing time was set to 11.5 hours, and the morphology of transition metal chalcogenide nanowires obtained was shown in Figure 5(b). The size of Figure 5(b) was 100nm×100nm, and the scanning conditions were 3V, 6pA. From Figure 5(b), it can be seen that all the boundaries of the MoSe2 thin film undergo a structural phase transition to form Mo 6 Se 6 Nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com