Piezoelectric ceramic material applied to high-temperature environment and preparation method of piezoelectric ceramic material

A technology of piezoelectric ceramics and high-temperature environment, which is applied in the field of materials, can solve the problems of unfavorable sensor stable operation, poor temperature stability of piezoelectric performance, and poor temperature response characteristics of sensors, etc. The effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A CBN-based high-temperature piezoelectric ceramic material with high Curie temperature, high high-temperature direct-current resistivity, good piezoelectric activity, and good thermal stability, which is oriented to high-temperature environments and a preparation method thereof, is characterized in that: the ceramic material The stoichiometric formula is Ca 0.8-δ Sr δ Bi 2 Nb 2-x-y Ta x W y o 9 +z wt% Li 2 CO 3 +w wt% Bi 2 o 3 +q wt% M, where M is a metal oxide, including but not limited to CeO 2 ,ZnO,Al 2 o 3 ,La 1.2 Ce 0.8 Ti 2 o 7 ,LiAlSiO 4 etc., 0≤δ≤0.2, 02 CO 3 、 Bi 2 o 3and metal oxide M added to the ceramic, the low melting point Li 2 CO 3 、 Bi 2 o 3 As a liquid-phase sintering agent, the metal oxide is used as a sintering aid to promote ceramic sintering to obtain a dense ceramic body. Its specific preparation method comprises the following steps:

[0031] (1) Calculate the required quality of each raw material according to the chemica...

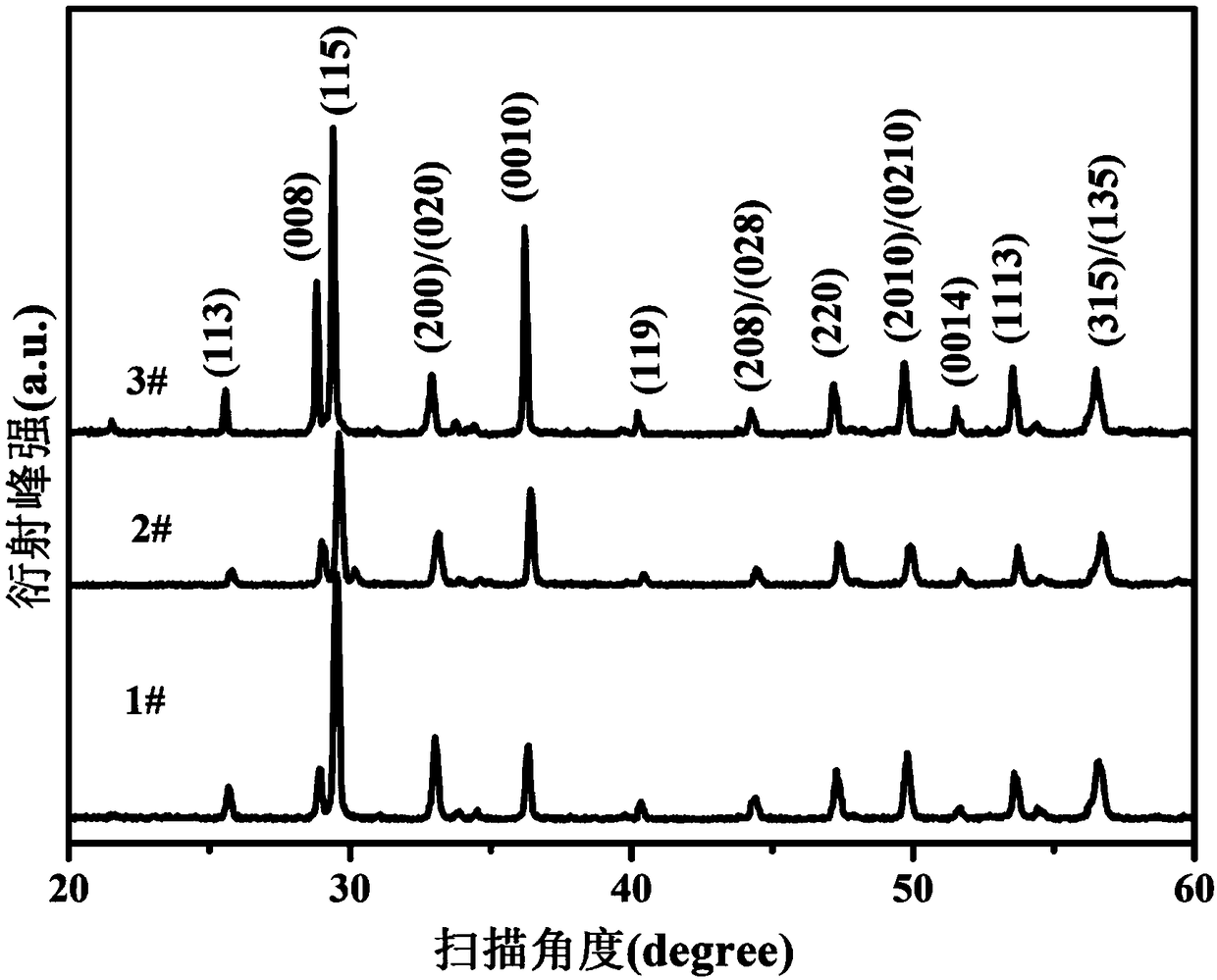

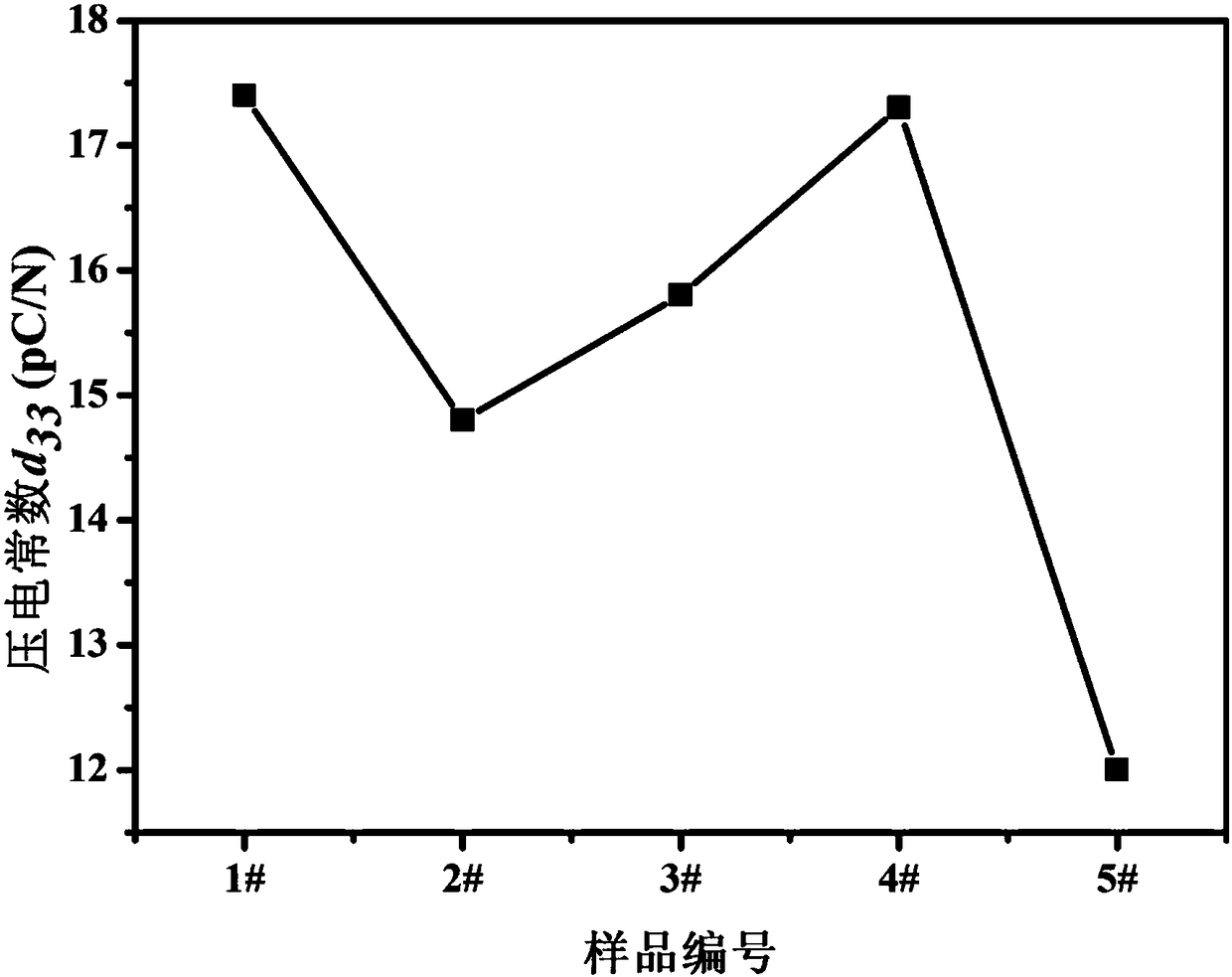

Embodiment 1

[0047] (1) Preparation of CBN-based piezoelectric ceramic powder by solid phase method

[0048] According to Ca 0.775 Sr 0.025 Bi 2 Nb 1.94 Ta 0.04 W 0.02 o 9 +0.45wt% Li 2 CO 3 +1.99wt% Bi 2 o 3 +0.63wt%CeO 2 (M=CeO 2 , δ = 0.025, x = 0.04, y = 0.02, z = 0.45, w = 1.99, q = 0.63, number 1#), accurately weigh the corresponding mass of powder according to the stoichiometric ratio. Put the weighed medicine in a nylon tank, use absolute ethanol as the dispersion medium, use a planetary ball mill ball for 24 hours, and the rotation speed is 200rpm, bake the slurry for 1-4 hours with a drying lamp or an oven, and then put it into a program temperature control box The temperature was continuously raised to 850°C in the furnace, and kept for 4 hours to obtain CBN-based piezoelectric ceramic powder;

[0049] (2) Secondary ball milling

[0050] Put the obtained CBN-based piezoelectric ceramic powder in a nylon tank, use absolute ethanol as the dispersion medium, and use a...

Embodiment 2

[0058] (1) Preparation of CBN-based piezoelectric ceramic powder by solid phase method

[0059] According to Ca 0.79 Sr 0.01 Bi 2 Nb 1.94 Ta 0.04 W 0.02 o 9 +0.45wt% Li 2 CO 3 +1.99wt% Bi 2 o 3 +0.3wt% Al 2 o 3 (M=Al 2 o 3 , δ = 0.01, x = 0.04, y = 0.02, z = 0.45, w = 1.99, q = 0.3, code 2#), according to the stoichiometric ratio, accurately weigh the corresponding mass of powder. Put the weighed medicine in a polyurethane ball mill tank, use absolute ethanol as the dispersion medium, use a planetary ball mill ball for 24 hours, and the rotation speed is 200rpm, bake the slurry with a drying lamp or oven for 1-4 hours, and then put it into a program temperature control box The temperature was continuously raised to 850°C in a type furnace and kept for 4 hours to obtain CBN-based piezoelectric ceramic powder;

[0060] (2) Secondary ball milling

[0061] Put the obtained CBN-based piezoelectric ceramic powder in a polyurethane ball mill tank, use absolute ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com