A kind of piezoelectric material with high Curie point and preparation method thereof

A technology of electrical materials and raw materials, applied in the field of materials, can solve the problems of increasing material costs, environmental protection piezoelectric ceramics, and electrical properties that cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

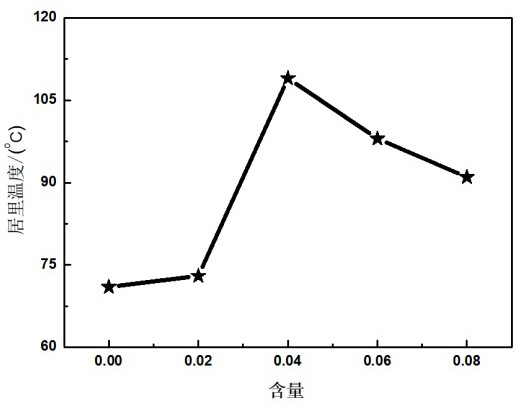

Image

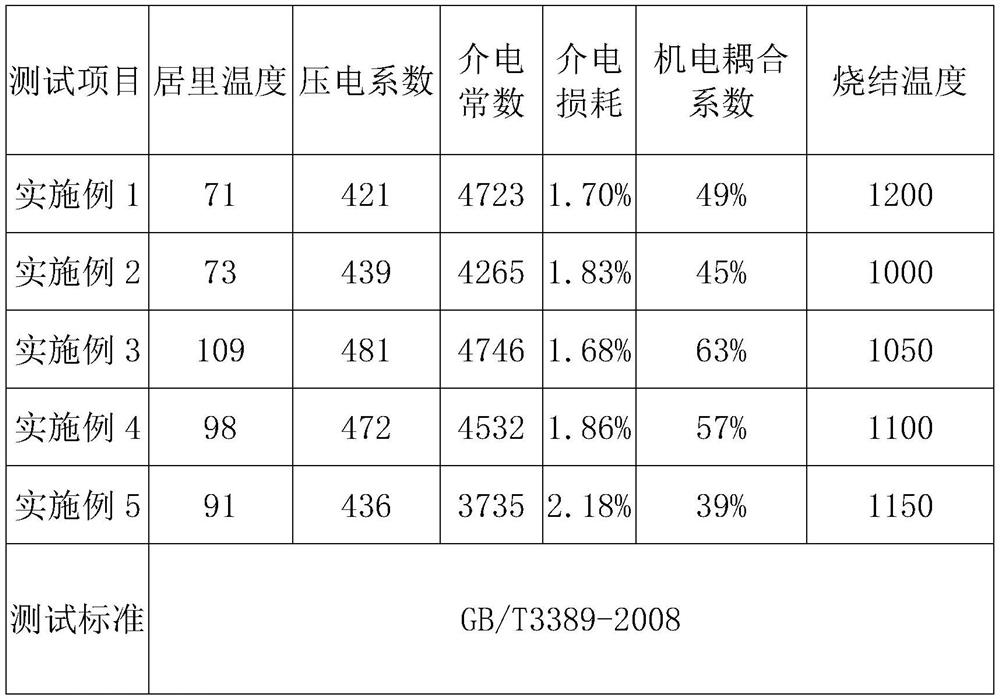

Examples

Embodiment 1

[0019] A preparation method of a high Curie point piezoelectric material, comprising the following steps:

[0020] (1) Press BaCO 3 60 servings, CaCO 3 3 parts, TiO 2 25 parts, ZrO 2 1 part, SnO 2 1 serving, Li 2 CO 3 0.4 part, using deionized water as the ball milling medium, ball milling the mixture for 6 hours, drying to complete dryness, and passing through a 50-mesh sieve;

[0021] (2) calcining the sieved material in an environment of 1000 ° C for 4 hours, and cooling to room temperature with the furnace;

[0022] (3) Use deionized water as the ball-milling medium for the cooled material, and after ball-milling for 6 hours, dry to complete dryness and pass through a 50-mesh sieve;

[0023] (4) adding 5% of its total weight polyvinyl butyral (PVB) in the dried material, and pressing it into a disc with a diameter of 10mm under a pressure of 10Mpa;

[0024] (5) Keep the wafer at 1200°C for 4h, cool it naturally to room temperature with the furnace, take it out, app...

Embodiment 2

[0026] A preparation method of a high Curie point piezoelectric material, comprising the following steps:

[0027] (1) Press BaCO 3 62 servings, CaCO 3 4 parts, TiO 2 26 parts, ZrO 2 2 parts, SnO 2 2 servings, Sm 2 O 3 0.02 part, Li 2 CO 3 0.5 parts of ingredients, use deionized water as the ball milling medium, ball mill the mixture for 8 hours, dry until completely dry, and pass through a 200-mesh sieve;

[0028] (2) The sieved material was calcined in an environment of 950 ° C for 4 hours, and cooled to room temperature with the furnace;

[0029] (3) Use deionized water as ball-milling medium for the cooled material, and after ball-milling for 8 hours, dry to complete dryness and pass through a 200-mesh sieve;

[0030] (4) adding the polyvinyl butyral (PVB) of 6% of its total weight in the material after drying, and pressing it into a disc with a diameter of 10mm under the pressure of 20Mpa;

[0031] (5) The wafer was kept at 1000°C for 4 hours, cooled naturally t...

Embodiment 3

[0033] A preparation method of a high Curie point piezoelectric material, comprising the following steps:

[0034] (1) Press BaCO 3 63 servings, CaCO3 5 parts, TiO 2 27 parts, ZrO 2 3 parts, SnO 2 3 servings, Sm 2 O 3 0.04 parts, Li 2 CO 3 0.6 parts of ingredients, use deionized water as the ball milling medium, ball mill the mixture for 10 hours, dry until completely dry, and pass through a 1000-mesh sieve;

[0035] (2) calcining the sieved material in an environment of 1000 ° C for 3.5 hours, and cooling to room temperature with the furnace;

[0036] (3) Use deionized water as the ball-milling medium for the cooled material, and after ball-milling for 10 hours, dry it until it is completely dry, and pass through a 1000-mesh sieve;

[0037] (4) adding the polyvinyl butyral (PVB) of 7% of its gross weight in the material after drying, and pressing it into a disc with a diameter of 10mm under the pressure of 20Mpa;

[0038] (5) The wafer was kept at 1050°C for 4 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com