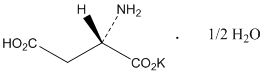

A kind of preparation method of potassium aspartate crystal

A technology of potassium aspartate and aspartic acid, applied in the field of preparation of potassium aspartate crystals, can solve the problems of large water consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At 20-25°C, add 40ml of pure water to a 2L three-necked reaction flask, turn on the mechanical stirring, add 133.0g of aspartic acid, turn on the heating to an internal temperature of 50-60°C, add 69.0g of potassium carbonate in batches, and wait for the reaction to be clarified Finally, keep stirring at 50-60°C for 1-2 hours, measure the pH value of 5.8-6.0, adjust the pH value to 6.5-6.8 with 1-2% (potassium carbonate weight percentage) of potassium carbonate; cool down to 40-50°C and add medicinal Activated carbon was stirred for 1-2 hours to filter, the filtrate was cooled to 15-25°C, 1130ml of isopropanol was added to the reaction solution, and the internal temperature was kept at -5-20°C to crystallize for 8-12 hours, suction filtered, and the filter cake was placed at 45 °C in a vacuum oven for 9 hours, collected the material, and obtained an off-white amorphous potassium aspartate hemihydrate product with a yield of 96.2%.

Embodiment 2

[0033] At 20-25°C, add 80ml of pure water to a 5L three-necked reaction flask, turn on the mechanical stirring, add 266.2g of aspartic acid, turn on the heating to an internal temperature of 50-60°C, add 138.2g of potassium carbonate in batches, and wait for the reaction to be clarified Finally, keep stirring at 50-60°C for 1-2 hours, measure the pH value of 5.8-6.0, adjust the pH value to 6.5-6.8 with 1-2% (potassium carbonate weight percentage) of potassium carbonate, cool down to 40-50°C and add medicinal Activated carbon was stirred for 1-2 hours to filter, the filtrate was cooled to 15-25°C, 2260ml of isopropanol was added to the reaction solution, and the internal temperature was kept at -5-20°C to crystallize for 8-12 hours, suction filtered, and the filter cake was placed at 45 °C in a vacuum oven for 9 hours, collected the material, and obtained an off-white amorphous potassium aspartate hemihydrate product with a yield of 96.5%.

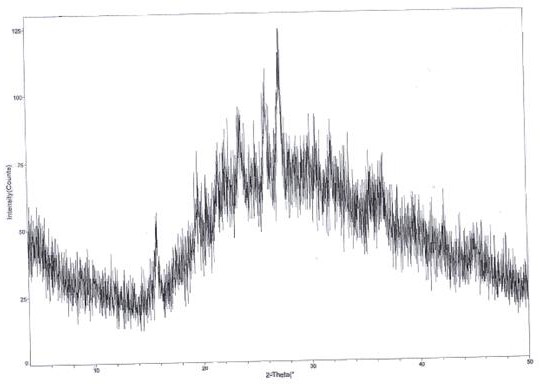

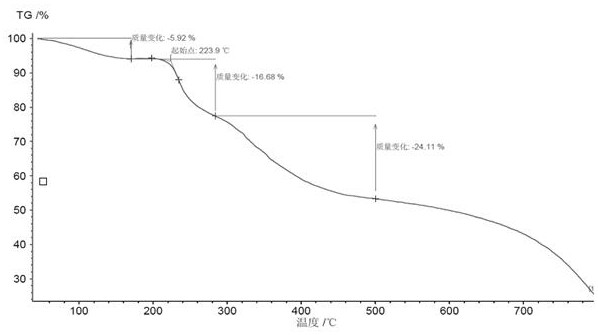

[0034] Perform XRD diffraction and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com