Conductive polymer wave-absorption sponge and preparation method thereof

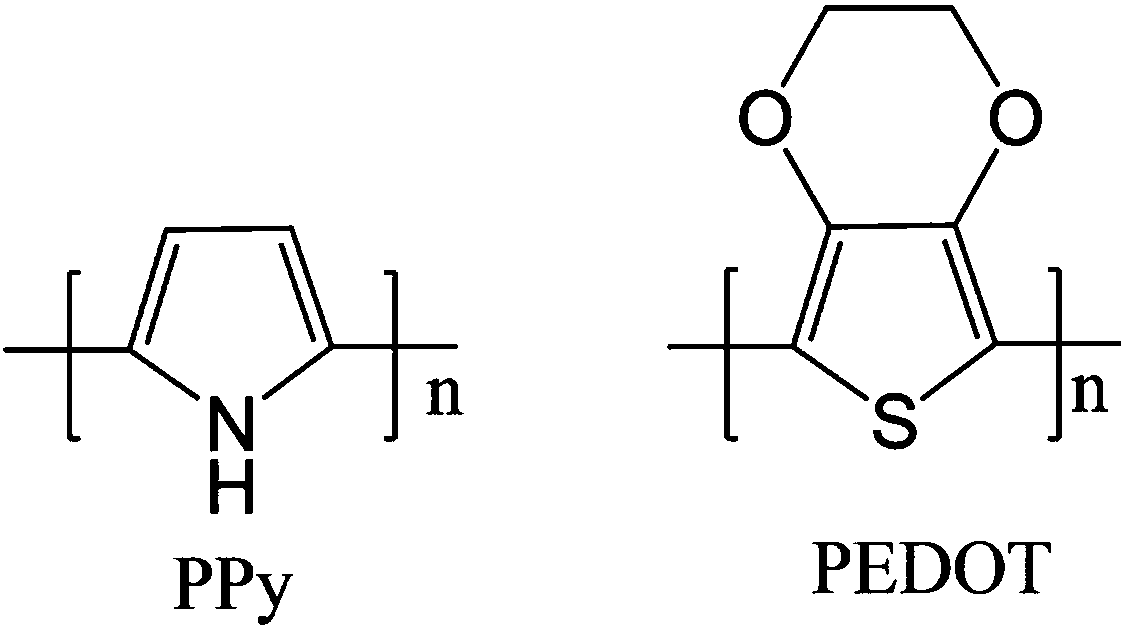

A conductive polymer, polyurethane sponge technology, applied in the field of conductive polymer absorbing sponge, can solve the problem of not eradicating electromagnetic waves, and achieve the effects of excellent broadband absorbing performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

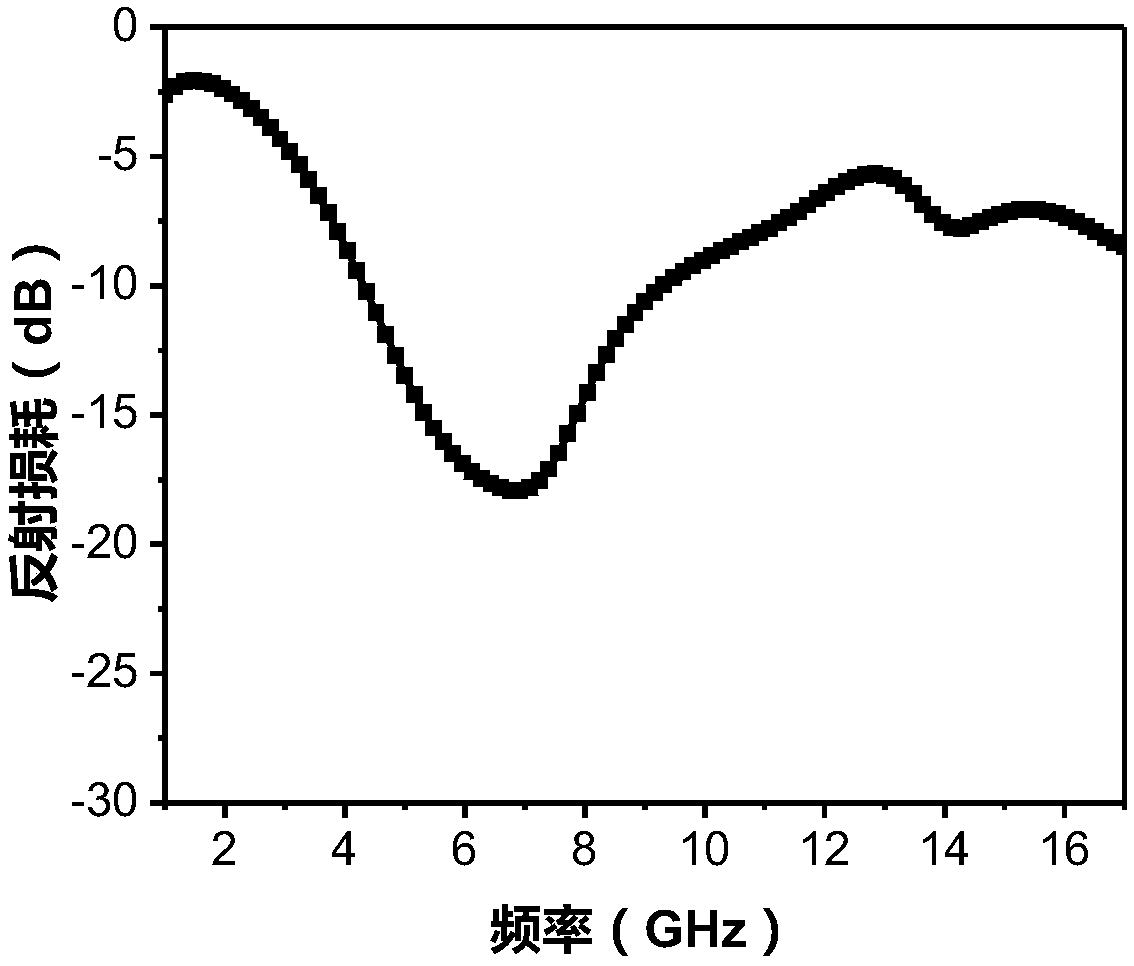

[0030] Embodiment 1 of the present invention, a preparation method of conductive polymer wave-absorbing sponge, it specifically comprises the following steps:

[0031] S1. Cut the polyurethane foam sponge with a thickness of 1cm into 18×18cm squares, then soak it in 270g / L FeCl3.6H2O solution for 10 minutes, squeeze the sponge to recover most of the FeCl3.6H2O solution, and place the squeezed sponge in a vacuum Vacuum drying at a temperature of 30-50°C in a drying oven to obtain a polyurethane sponge that adsorbs FeCl3.6H2O;

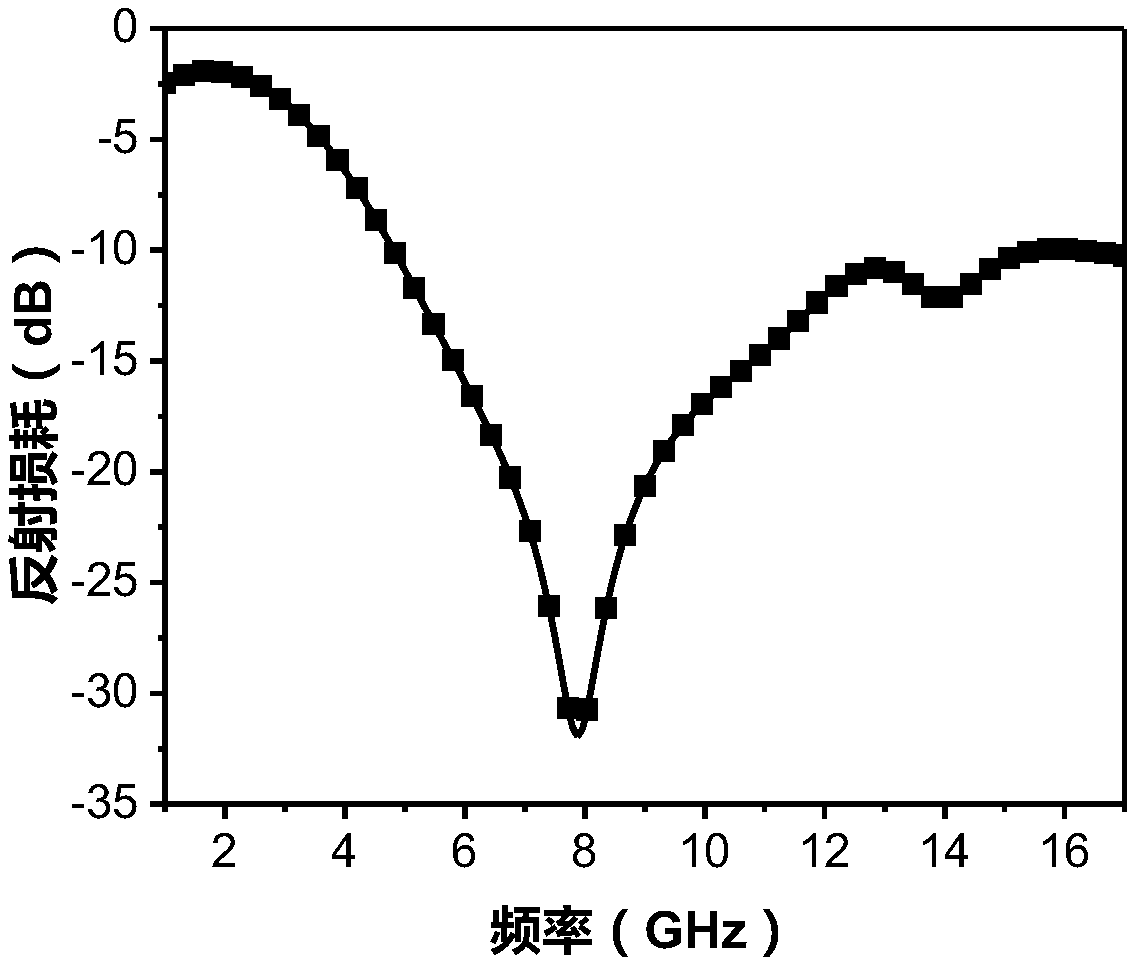

[0032] S2. Put the polyurethane sponge obtained in step 1 into a vacuum heating box, and put it into an open bottle filled with pyrrole monomer, keep the vacuum at 0.01MPa, control the temperature at 30°C, and deposit for 2 hours to obtain a conductive polymer. Absorbing sponge sample 1;

Embodiment 2

[0033] Embodiment 2 of the present invention, a preparation method of a conductive polymer wave-absorbing sponge, specifically comprises the following steps:

[0034] S1. Cut the polyurethane foam sponge with a thickness of 1cm into 18×18cm squares, then soak it in 228g / L ammonium persulfate solution for 10 minutes, squeeze the sponge to recover most of the FeCl3.6H2O solution, and put the squeezed sponge in Vacuum drying at a temperature of 30-50°C in a vacuum drying oven to obtain a polyurethane sponge that adsorbs FeCl3.6H2O;

[0035] S2. Put the polyurethane sponge obtained in step 3 into a vacuum heating box, and put it into an open bottle filled with pyrrole monomer, keep the vacuum at 0.01MPa, control the temperature at 30°C, and deposit for 24 hours to obtain a conductive polymer Absorbing sponge sample 2;

Embodiment 3

[0036] Embodiment 3 of the present invention, a preparation method of a conductive polymer wave-absorbing sponge, specifically comprises the following steps:

[0037] S1. Cut the polyurethane foam sponge with a thickness of 2cm into 18×18cm squares, then soak it in 270g / L FeCl3.6H2O solution for 10 minutes, squeeze the sponge to recover most of the FeCl3.6H2O solution, and place the squeezed sponge in a vacuum Vacuum drying at a temperature of 30-50°C in a drying oven to obtain a polyurethane sponge that adsorbs FeCl3.6H2O;

[0038] S2. Put the polyurethane sponge obtained in step 1 into a vacuum heating box, and put it into an open bottle filled with 3,4-ethylenedioxythiophene, keep the vacuum at 0.01MPa, control the temperature at 30°C, and the deposition time for 12 hours , to obtain conductive polymer wave-absorbing sponge sample 3;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com