Fireproof coating for floor

A technology for fire-resistant coatings and floors, applied in fire-resistant coatings, coatings, etc., can solve problems such as unsatisfactory, and achieve the effect of good high temperature resistance and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of flame retardant is:

[0021] Add nano-silica to the polypolyol phosphate liquid for ultrasonic dispersion to obtain a suspension. After the suspension is heated to 85°C, vinyltrimethoxysilane is added dropwise to react. After the end, it can be dried by centrifugal vacuum. The mass ratio of nano-silica, polypolyol phosphate and vinyltrimethoxysilane is 5:14:1.

Embodiment 2

[0023] The preparation method of flame retardant is:

[0024] Add nano-silica to the polypolyol phosphate liquid for ultrasonic dispersion to obtain a suspension. After the suspension is heated to 80°C, γ-methacryloxypropyltrimethoxysilane is added dropwise to react. After the end Centrifuge and vacuum dry. The mass ratio of nano silicon dioxide, polypolyol phosphate and γ-methacryloxypropyltrimethoxysilane is 8:17:3.

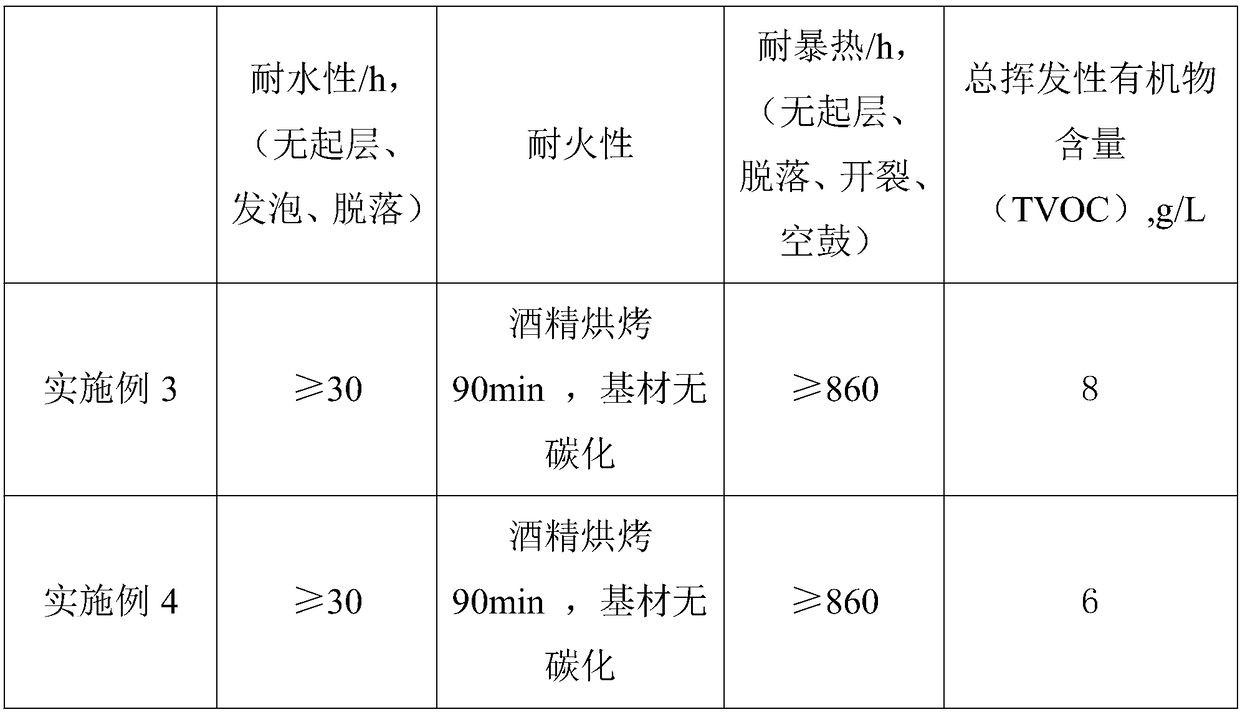

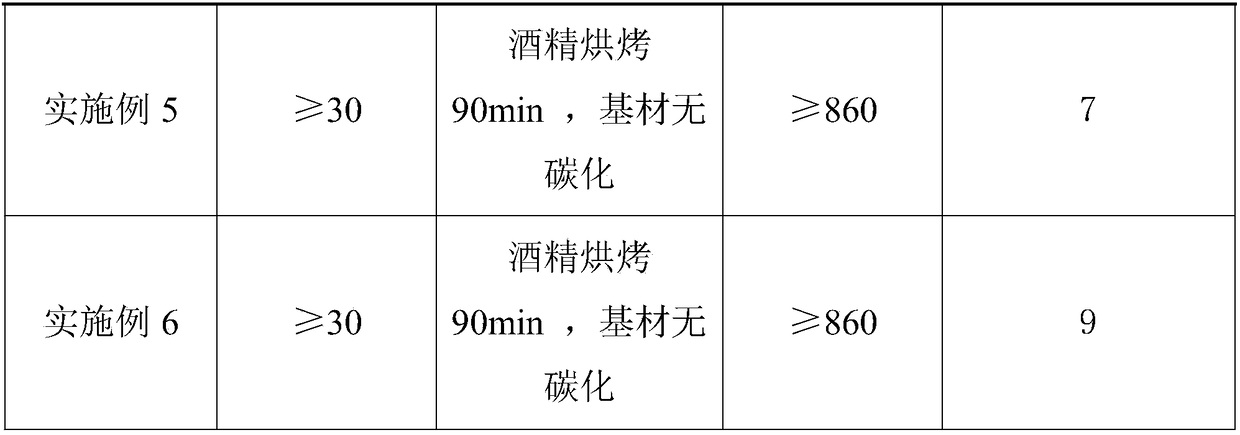

Embodiment 3

[0026] A kind of fireproof paint for floor, comprises following components according to parts by weight:

[0027] 50 parts of acrylic emulsion, 28 parts of silicon acrylic emulsion, 6 parts of vermiculite powder, 7 parts of superfine dolomite, 12 parts of flame retardant of Example 1, 0.6 part of sodium hexametaphosphate wetting agent, 0.5 part of water-based acrylate copolymer And 10 parts of titanium dioxide, 10 parts of montmorillonite. The acrylic emulsion is an acrylic emulsion with a solid content of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com