Nickel-aluminum-chromium-molybdenum-iron eutectic alloy and preparation method thereof

A eutectic alloy, chromium-molybdenum technology, applied in the field of nickel-aluminum-based eutectic alloy and its preparation, can solve problems such as reducing fracture toughness at room temperature, and achieve the effects of excellent mechanical properties, improved toughness, and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

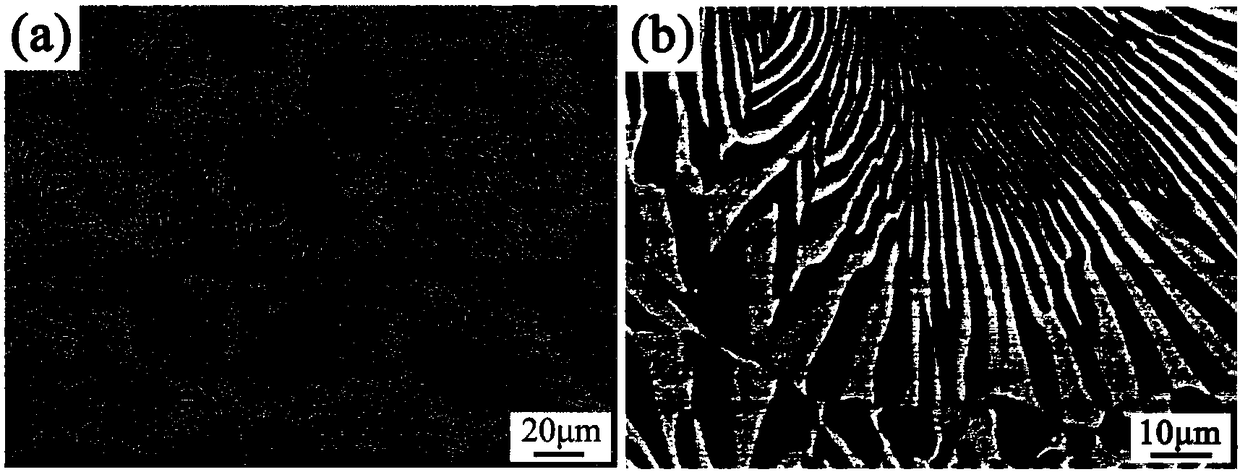

[0031] The preparation method of a kind of nickel-aluminum-chromium-molybdenum-iron eutectic alloy of the present invention is specifically implemented according to the following steps:

[0032] Step 1, weighing raw materials according to the composition of the atomic percentage of the alloy;

[0033] Specifically, Ni block, Al rod, Cr sheet, Mo wire and Fe rod are weighed according to the atomic percentage of NiAl-28Cr-6Mo-xFe;

[0034] Among them, the purity of Ni blocks is 99.9-99.96wt%, the purity of Al rods is 99.9-99.99wt%, the purity of Cr flakes is 99.7-99.9wt%, the purity of Mo silk is 99.9-99.95wt%, and the purity of Fe rods is 99.9 ~99.96wt%;

[0035] Step 2, pre-treat the raw materials weighed in step 1. The specific method is to polish the Mo wire, Ni block and Fe rod, and pickle the Al rod to remove the scale on the surface of the raw material, wherein the pickling solution According to concentrated HCl and H 2 The volume ratio of O is 0.9~1.1:1 for proportion...

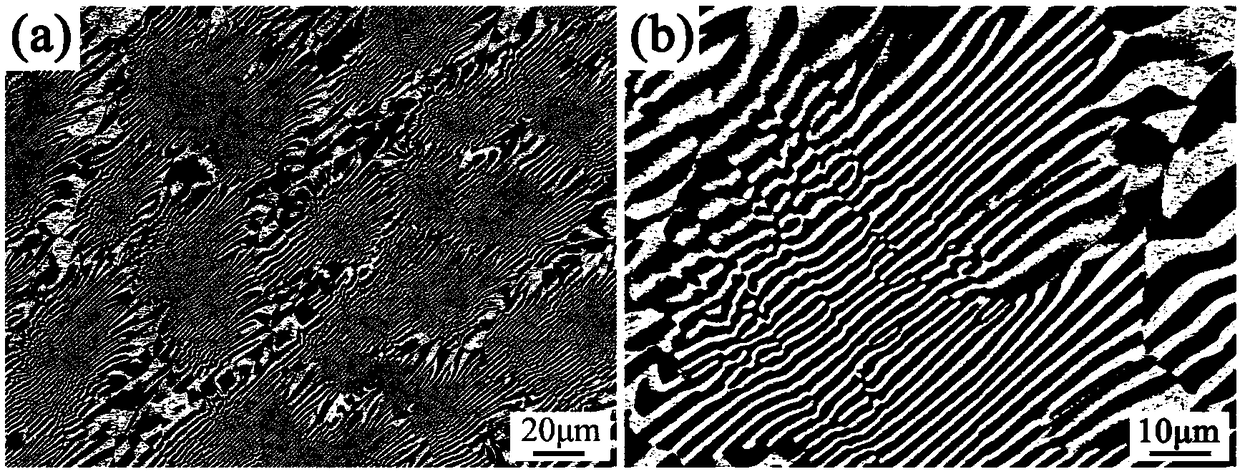

Embodiment 1

[0042] A nickel-aluminum-chromium-molybdenum-iron eutectic alloy, which consists of NiAl-28Cr-6Mo-2Fe, wherein Ni and Al are in an equal atomic ratio; specifically, it is prepared by the following method,

[0043] Step 1, weighing raw materials according to the composition of the atomic percentage of the alloy;

[0044]Specifically, according to the atomic percentage of NiAl-28Cr-6Mo-2Fe, weigh Ni blocks, Al rods, Cr flakes, Mo filaments, and Fe rods; among them, the atomic ratios of Ni and Al are equal, and the purity of Ni blocks is 99.9-99.96wt% , the purity of Al rods is 99.9-99.99wt%, the purity of Cr flakes is 99.7-99.9wt%, the purity of Mo wire is 99.9-99.95wt%, and the purity of Fe rods is 99.9-99.96wt%;

[0045] Step 2, pre-treat the raw materials weighed in step 1. The specific method is to polish the Mo wire, Ni block and Fe rod, and pickle the Al rod to remove the scale on the surface of the raw material, wherein the pickling solution According to concentrated HCl...

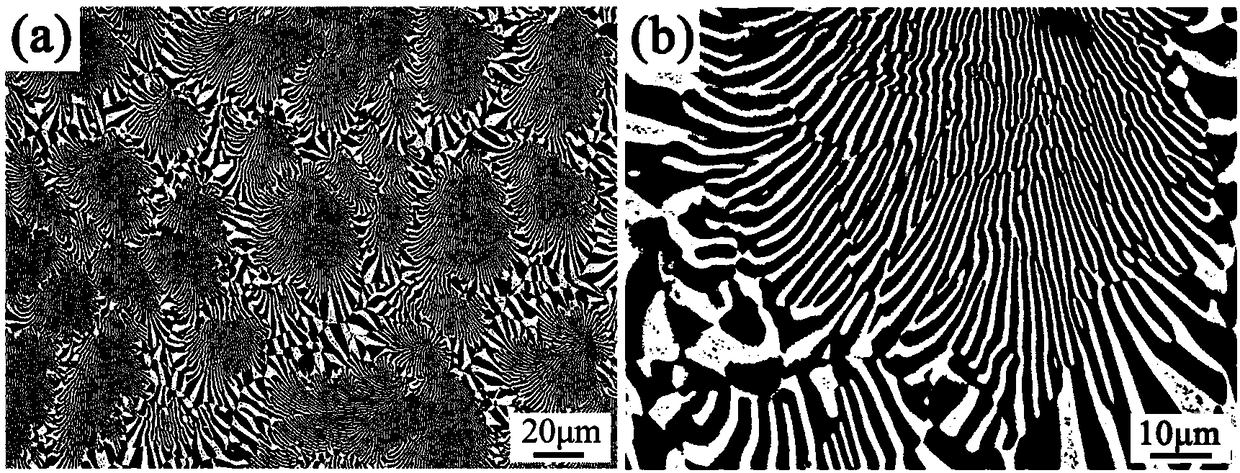

Embodiment 2

[0053] A nickel-aluminum-chromium-molybdenum-iron eutectic alloy, which consists of NiAl-28Cr-6Mo-5Fe, wherein Ni and Al are in an equal atomic ratio; specifically, it is prepared by the following method,

[0054] Step 1, weighing raw materials according to the composition of the atomic percentage of the alloy;

[0055] Specifically, according to the atomic percentage of NiAl-28Cr-6Mo-5Fe, weigh Ni blocks, Al rods, Cr flakes, Mo filaments, and Fe rods; among them, the atomic ratios of Ni and Al are equal, and the purity of Ni blocks is 99.9-99.96wt% , the purity of Al rods is 99.9-99.99wt%, the purity of Cr flakes is 99.7-99.9wt%, the purity of Mo wire is 99.9-99.95wt%, and the purity of Fe rods is 99.9-99.96wt%;

[0056] Step 2, pre-treat the raw materials weighed in step 1. The specific method is to polish the Mo wire, Ni block and Fe rod, and pickle the Al rod to remove the scale on the surface of the raw material, wherein the pickling solution According to concentrated HC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com