A high-quality preparation method of a short-arc spherical crown drug-shaped mask

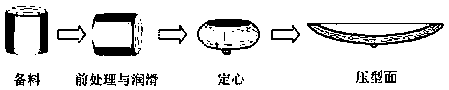

A medicine type cover and arc technology, which is applied in the field of precision machining of short arc spherical cap medicine type cover, can solve the problems of poor surface quality and uneven organization of turning machining, and achieve the improvement of tool life, reduction of cutting temperature and material utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of the blank: The outer diameter of the short-arc spherical cap is 108mm, the outer spherical radius is 118mm, the inner spherical radius is 142mm, the cone angle is 27°, the spherical crown height is 23.2mm, and the bottom wall thickness is 3.5mm; Processing forming theory and nearly uniform plastic deformation principle, leaving a 3mm machining allowance on one side of the flange part of the outer diameter of the medicine cover, and designing a φ4mm positioning bump at the bottom of the spherical center of the medicine cover; using UG and DEFORM software The forming process is simulated, analyzed and optimized, the volume and size of the blank are calculated, and the diameter of Ta2.5W alloy bar is φ50×21.5mm.

[0037] (2) Rotary riveting forming: Put the blank obtained in step (1) into the cavity of the pre-forming mold, using a hydraulic rotary riveting machine (MYXM6300), under the action of three-directional compressive stress, the riveting head speed ...

Embodiment 2

[0047] (1) The preparation of the blank: the diameter of the short-arc spherical cap is 139mm, the outer spherical radius is 140mm, the inner spherical radius is 155mm, the cone angle is 33°, the spherical crown height is 23.8mm, and the bottom wall thickness is 3.8mm; according to plasticity Processing forming theory and nearly uniform plastic deformation principle, leaving a 3mm machining allowance on one side of the flange part of the outer diameter of the medicine cover, and designing a φ4mm positioning bump at the bottom of the spherical center of the medicine cover; using UG and DEFORM software The forming process is simulated, analyzed and optimized, the blank volume and size specifications are calculated, and the diameter of the Ta5W alloy bar is φ65×17mm.

[0048] (2) Rotary riveting forming: Put the blank obtained in step (1) into the cavity of the pre-forming mold, using a hydraulic rotary riveting machine (MYXM6300), under the action of three-way compressive stress, th...

Embodiment 3

[0058] (1) Preparation of the blank: The diameter of the short-arc spherical crown cap is 142mm, the outer spherical radius is 136mm, the inner spherical radius is 148mm, the spherical crown height is 24.6mm, and the bottom wall thickness is 4.8mm; according to the theory of plastic processing and nearly uniform The principle of plastic deformation is to leave a machining allowance of 3mm on one side of the flange part of the outer diameter of the medicine cover, and design a φ4mm positioning bump at the bottom of the spherical center of the medicine cover; use UG and DEFORM software to simulate and analyze the forming process. Optimize, calculate the blank volume and size specifications, choose Ta10W alloy bar diameter φ50×18mm.

[0059] (2) Rotary riveting forming: Put the blank obtained in step (1) into the cavity of the pre-forming mold, using a hydraulic rotary riveting machine (MYXM6300), under the action of three-way compressive stress, the riveting head speed is 1800r / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com