A method for preparing a modified ternary cathode material combined with cerium doping and carbon coating

A cathode material and carbon coating technology, which is applied in the field of preparation of modified ternary cathode materials by combining cerium doping and carbon coating, can solve the problems of restricting the development of lithium-ion batteries, low electronic conductivity, poor cycle performance, etc. , to achieve the effect of reducing the first irreversible capacity loss, optimizing the preparation process, and improving the charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

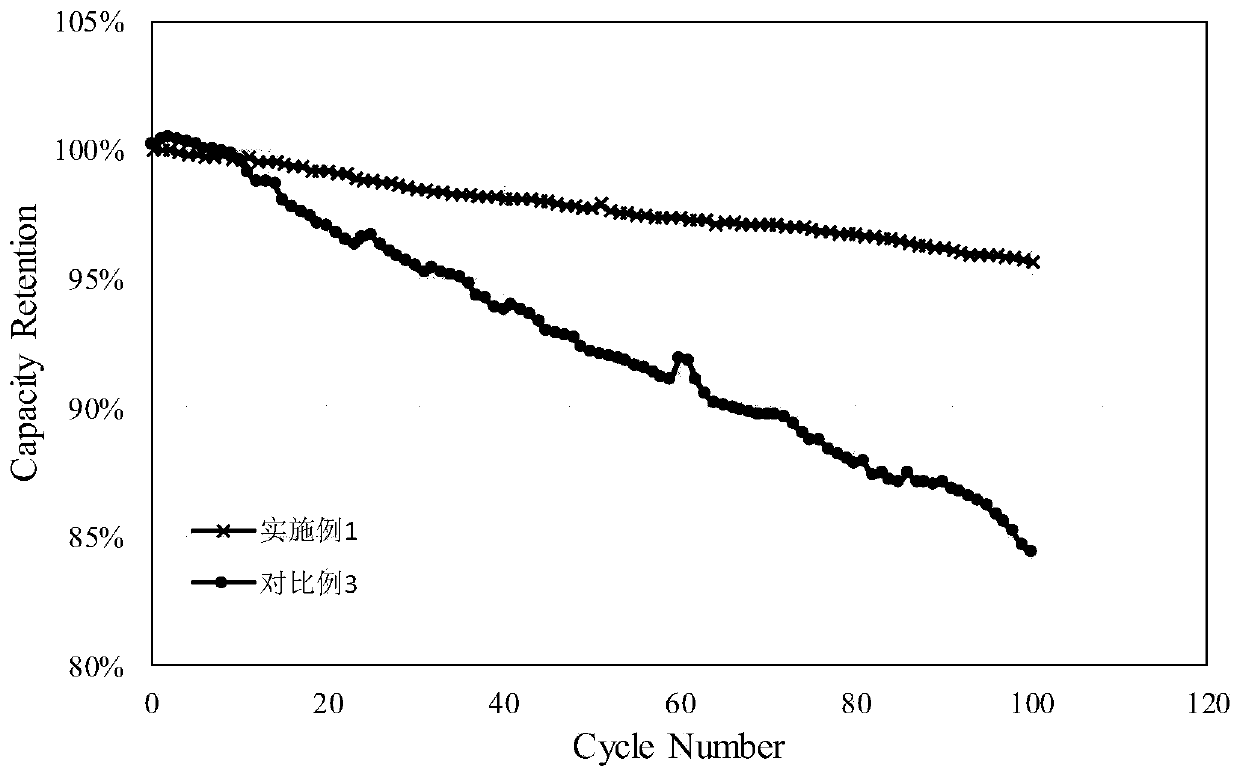

Image

Examples

Embodiment 1

[0025] A method for preparing a modified ternary positive electrode material in combination with cerium doping and carbon coating proposed by the present invention comprises the following steps:

[0026] S1, the NiSO 4 , MnSO 4 、CoSO 4 , Ce(NO 3 ) 3 Prepare a uniformly mixed solution with a molar ratio of 5:5:4:1, then slowly add it dropwise into the NaOH solution, stir for 2 hours under the system of pH=11, let it settle, filter, wash with water until neutral, and Dry at 100°C for 30 hours to obtain the precursor of the positive electrode material;

[0027] S2. Mix the positive electrode material precursor and LiOH in absolute ethanol, and use a planetary ball mill for ball milling. The grinding medium is agate balls. The ball milling speed is 200r / min, the ball milling time is 4h, and then the heating rate is 5°C / min. Raise the temperature to 500°C and keep it warm for 10 hours to obtain the activated material; among them, the Ni in the precursor of the positive electro...

Embodiment 2

[0030] A method for preparing a modified ternary positive electrode material in combination with cerium doping and carbon coating proposed by the present invention comprises the following steps:

[0031] S1, the NiSO 4 , MnSO 4 、CoSO 4 , Ce(NO 3 ) 3 Prepare a uniformly mixed solution with a molar ratio of 15:4:9:2, then slowly add it dropwise into the NaOH solution, stir for 2 hours under the system of pH=11, let it settle, filter, wash with water until neutral, and Dry at 100°C for 30 hours to obtain the precursor of the positive electrode material;

[0032] S2. Mix the positive electrode material precursor and LiOH in absolute ethanol, and use a planetary ball mill for ball milling. The grinding medium is agate balls. The ball milling speed is 200r / min, the ball milling time is 4h, and then the heating rate is 5°C / min. Raise the temperature to 500°C and keep it warm for 10 hours to obtain the activated material; among them, the Ni in the precursor of the positive electr...

Embodiment 3

[0035] A method for preparing a modified ternary positive electrode material in combination with cerium doping and carbon coating proposed by the present invention comprises the following steps:

[0036] S1, the NiSO 4 , MnSO 4 、CoSO 4 , Ce(NO 3 ) 3 Prepare a uniformly mixed solution with a molar ratio of 24:1:3:2, then slowly add it dropwise into the NaOH solution, stir for 2 hours under the system of pH=11, let it settle, filter, wash with water until neutral, and Dry at 100°C for 30 hours to obtain the precursor of the positive electrode material;

[0037] S2. Mix the positive electrode material precursor and LiOH in absolute ethanol, and use a planetary ball mill for ball milling. The grinding medium is agate balls. The ball milling speed is 200r / min, the ball milling time is 4h, and then the heating rate is 5°C / min. Raise the temperature to 500°C and keep it warm for 10 hours to obtain the activated material; among them, the Ni in the precursor of the positive electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com