Capsule brewing type herbaceous plant tea drink as well as preparation and use methods thereof

A herbal plant brewing technology, which is applied to plant raw materials, medical raw materials derived from gymnosperms, plant/algae/fungi/moss components, etc., can solve the problems of traditional Chinese medicine herbal capsule drinks that have not yet appeared, and avoid water insolubility The precipitation of macromolecular impurities, the effect of delicious and rich taste, beautiful and clear soup color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Lily 1kg, seabuckthorn 2kg, medlar 1kg, torreya 1kg, blood glutinous rice 2kg.

[0052] Preparation Process:

[0053] (1) Lily, seabuckthorn, medlar, and torreya among the above raw materials are crushed to a 20-mesh sieve, and supercritical extraction with carbon dioxide is carried out at an extraction temperature of 36° C., a pressure of 10 MPa, a time of 1 hr, and a flow rate of carbon dioxide of 100 L / hr to obtain 5 ml of an extract ;

[0054] (2) Use 15g of dextrin to uniformly mix the extract, stir for 1 hr, pass through a 20-mesh sieve, and leave it in a closed place for 24 hrs, and mix with the fried glutinous rice and the above-mentioned medicinal materials after supercritical extraction;

[0055] (3) Packed in brewable capsules, 5g per capsule.

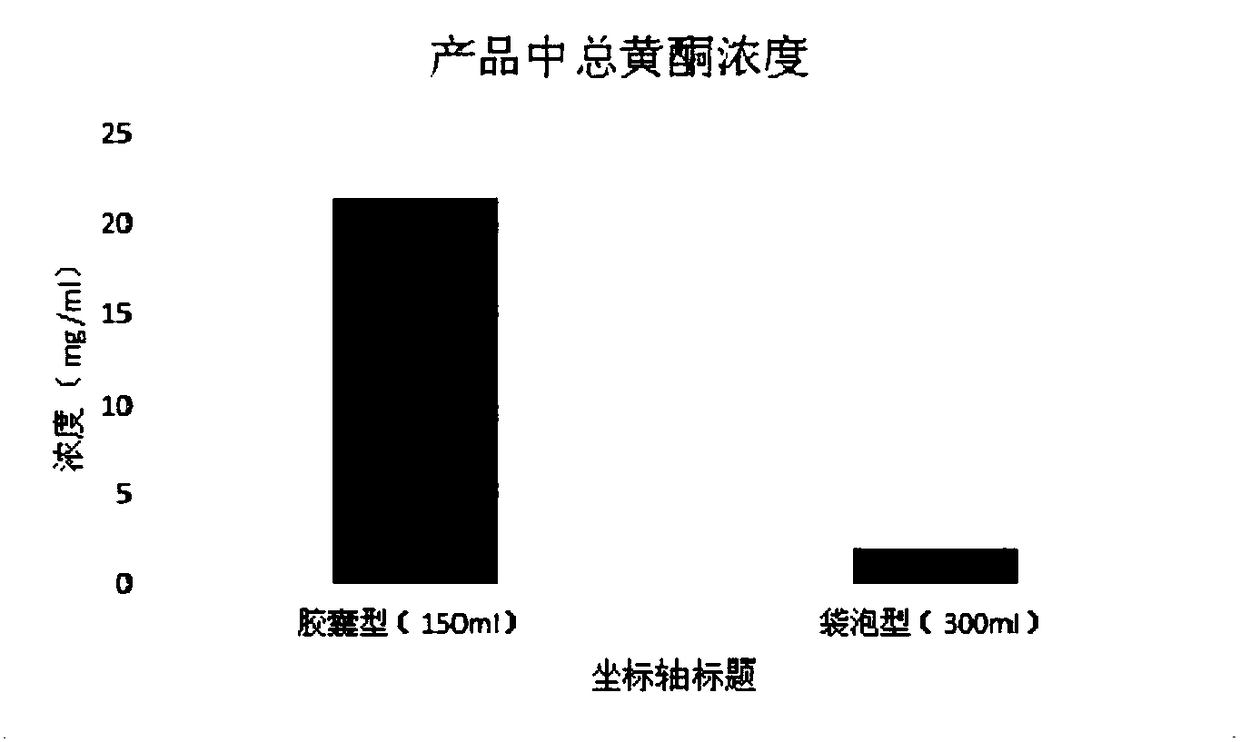

[0056] Brewing: use a capsule brewing machine to brew, 5g of tea, 150ml of water, the temperature of the brewing water is 95°C, the pressure is 8MPa, and the brewing time is 2 minutes. The 2-minute brewing experime...

Embodiment 2

[0059] Lily 2kg, seabuckthorn 4kg, medlar 2kg, torreya 2kg, blood glutinous rice 4kg.

[0060] Preparation Process:

[0061] (1) Lily, seabuckthorn, medlar, and torreya among the above raw materials are crushed to a 40-mesh sieve, and supercritical extraction with carbon dioxide is carried out at an extraction temperature of 33° C., a pressure of 9.0 MPa, a time of 1 hr, and a flow rate of carbon dioxide of 150 L / hr to obtain an extract 10ml;

[0062] (2) Use 30g of dextrin to uniformly mix the extract, stir for 1 hr, pass through a 30-mesh sieve, seal and let stand for 18 hr, and mix with the fried blood glutinous rice and the above-mentioned medicinal materials after supercritical extraction;

[0063] (3) Packed in brewable capsules.

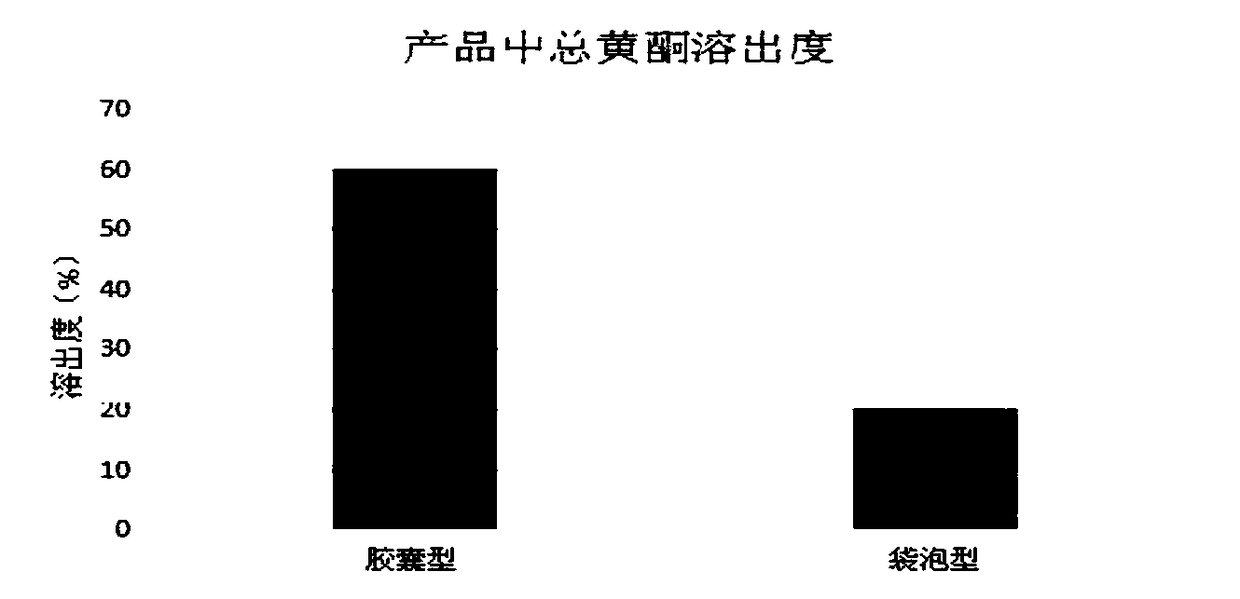

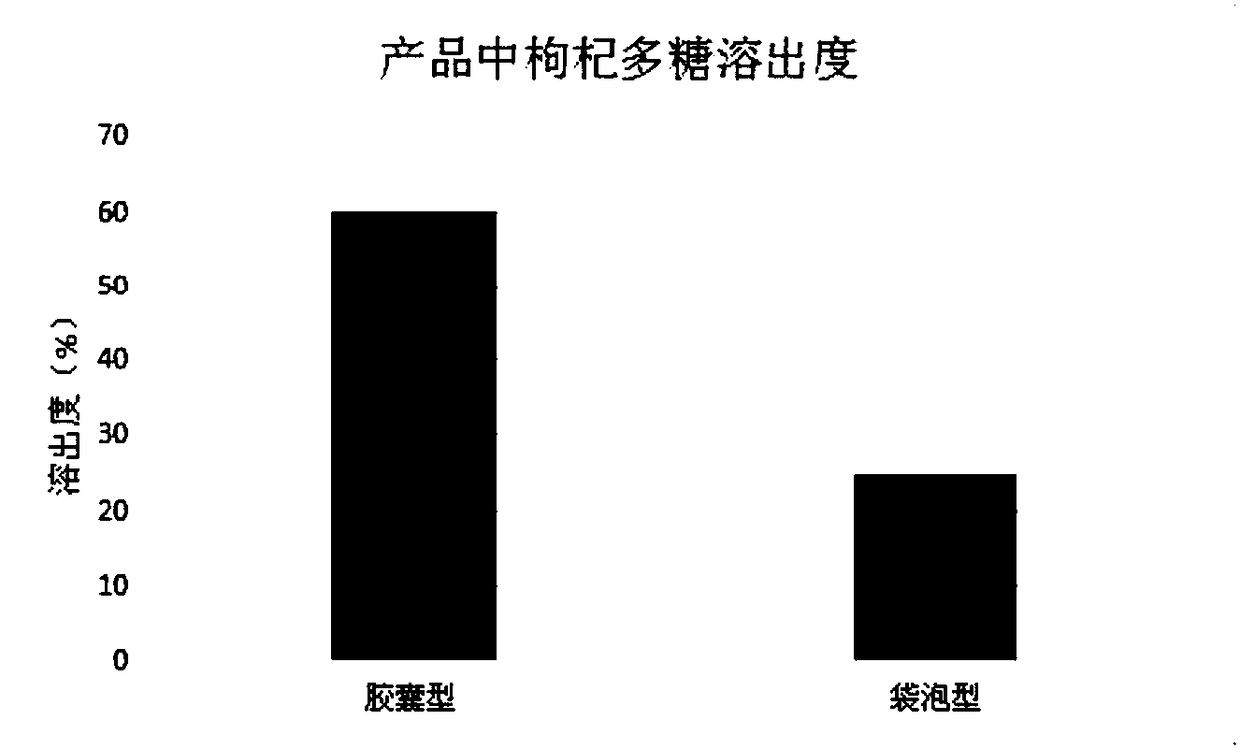

[0064] Brewing: Use a capsule brewing machine for brewing. 5g tea, 200ml water, brewing water temperature 100°C, pressure 6.5MPa. The brewing time is 4 minutes. The dissolution curve experiments of capsule type and brewing type effective ...

Embodiment 3

[0066] Lily 5kg, seabuckthorn 10kg, medlar 5kg, torreya 5kg, blood glutinous rice 10kg.

[0067] Preparation Process:

[0068] (1) Lily, seabuckthorn, medlar, and torreya among the above raw materials were pulverized to 60 mesh, and extracted by supercritical carbon dioxide at an extraction temperature of 35° C., a pressure of 11 MPa, a time of 2.0 hr, and a flow rate of carbon dioxide of 200 L / hr to obtain 7.5 ml of an extract ;

[0069] (2) Utilize 21.5g dextrin to uniformly mix the extract, stir for 1hr, pass through a 60-mesh sieve, airtightly stand for 30hr, and mix with the fried blood glutinous rice and the medicinal materials after the above-mentioned supercritical extraction;

[0070] (3) Packed in brewable capsules.

[0071] Brewing: Use a capsule brewing machine for brewing. 5g tea, 150ml water, brewing water temperature 85°C, pressure 7.0MPa. The brewing time is 5 minutes.

[0072] Comparing the capsule type and the tea in bag (the raw material and the capsule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com