Antibacterial wet tissue

A technology for wet wipes and antibacterial additives, applied in the field of daily necessities, can solve the problem that wet wipes do not have antibacterial properties, etc., achieve stable and efficient antibacterial effect, solve the problem of insufficient antibacterial performance, and solve the effect of not easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

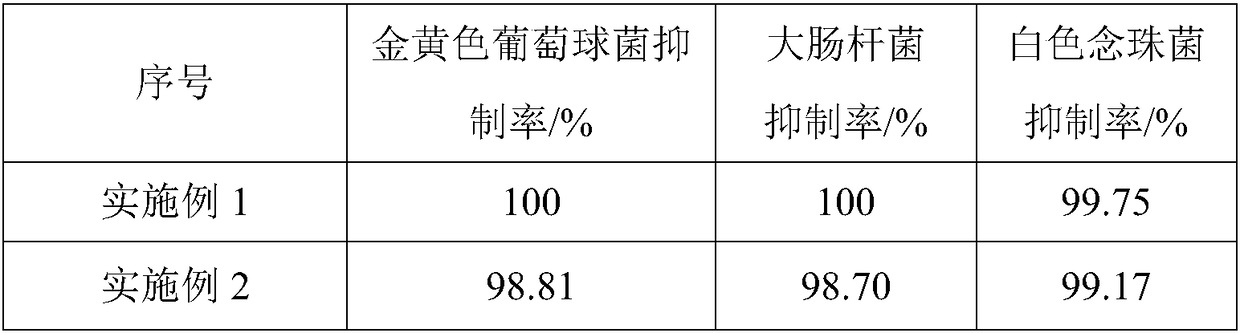

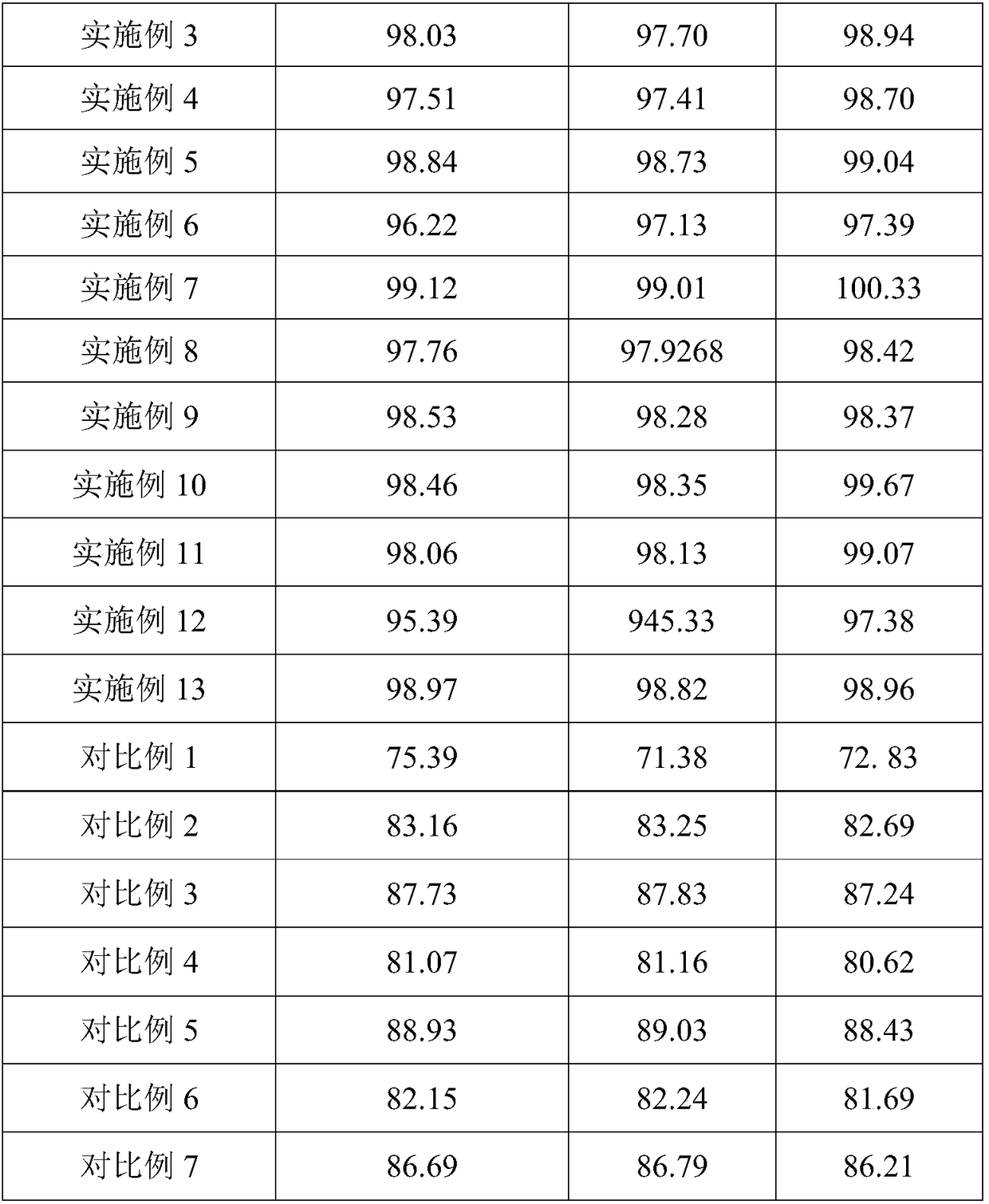

Examples

Embodiment 1

[0023] An antibacterial wet tissue is prepared by the following method:

[0024] S1. Mix wood pulp fibers and cotton fibers to make pulp, obtain shaped fiber paper base by papermaking, and apply graphene modified cellulose antibacterial additives by spraying between the front and rear drying procedures of the fiber paper base to obtain wet wipes Substrate;

[0025] S2. Soak the wet tissue substrate in S1 in the soaking solution, take out the wet tissue substrate to obtain an antibacterial wet tissue,

[0026] The antibacterial auxiliary agent in the S1 is graphene oxide modified cellulose, and the consumption of the antibacterial auxiliary agent is 2% of the slurry quality;

[0027] Among them, the graphene oxide modified cellulose antibacterial auxiliary agent is prepared by the following method: prepare a mixed solution of strong alkali, urea and thiourea, cool to -10~-20°C, stir and add the cellulose solution in S11 and the evenly dispersed Graphene oxide solution, keep t...

Embodiment 12

[0033] An antibacterial wet tissue is prepared by the following method:

[0034] S1. Mix wood pulp fibers and cotton fibers to make pulp, obtain shaped fiber paper base by papermaking, and apply graphene modified cellulose antibacterial additives by spraying between the front and rear drying procedures of the fiber paper base to obtain wet wipes Substrate;

[0035] S2. Soak the wet tissue substrate in S1 in the soaking solution, take out the wet tissue substrate to obtain an antibacterial wet tissue,

[0036] The antibacterial auxiliary agent in the S1 is graphene oxide modified cellulose, and the consumption of the antibacterial auxiliary agent is 2% of the slurry quality;

[0037] Among them, the graphene oxide modified cellulose antibacterial auxiliary agent is prepared by the following method: prepare a mixed solution of strong alkali, urea and thiourea, cool to -10~-20°C, stir and add the cellulose solution in S11 and the evenly dispersed Graphene oxide solution, keep t...

Embodiment 13

[0040] An antibacterial wet tissue is prepared by the following method:

[0041] S1. Mix wood pulp fibers and cotton fibers to make pulp, obtain shaped fiber paper base by papermaking, and apply graphene modified cellulose antibacterial additives by spraying between the front and rear drying procedures of the fiber paper base to obtain wet wipes Substrate;

[0042] S2. Soak the wet tissue substrate in S1 in the soaking solution, take out the wet tissue substrate to obtain an antibacterial wet tissue,

[0043] The antibacterial auxiliary agent in the S1 is graphene oxide modified cellulose, and the consumption of the antibacterial auxiliary agent is 2% of the slurry quality;

[0044] Among them, the graphene oxide modified cellulose antibacterial auxiliary agent is prepared by the following method: prepare a mixed solution of strong alkali, urea and thiourea, cool to -10~-20°C, stir and add the cellulose solution in S11 and the evenly dispersed Graphene oxide solution, keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com