Method for recycling calcium fluoride from dolomite type magnetite magnetically-separated tailings

A technology for magnetic separation of tailings and magnetite, which is applied in the field of comprehensive recovery and utilization of mineral resources, can solve the problems of difficult separation of mixed minerals in tailings resource recovery, and achieves the advantages of reducing flotation cost, low usage, and improving recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

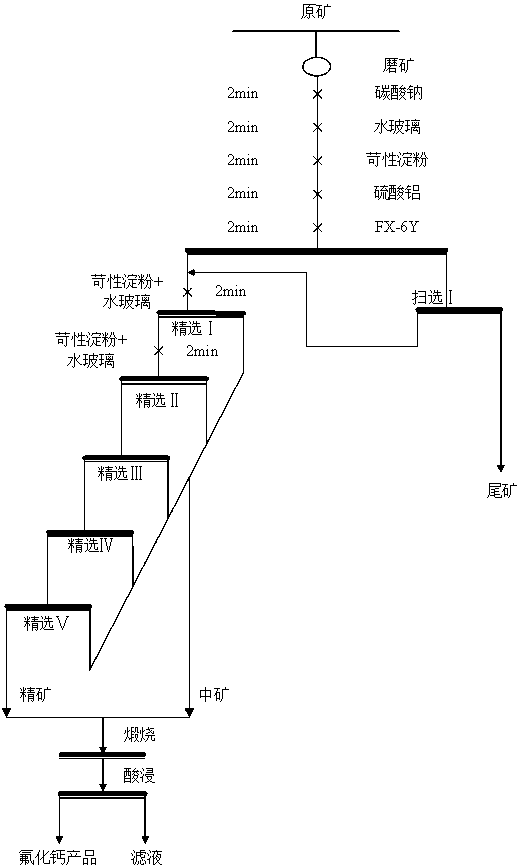

[0041] Embodiment 1, comprises the following steps:

[0042] (1) Grinding operation:

[0043] The dolomite-type magnetite magnetic separation tailings are further finely ground to -0.074mm, accounting for 93.10%;

[0044] (2) Flotation operation:

[0045] a. Rough selection: Sodium carbonate, water glass, and aluminum sulfate are formulated into a 5% solution by mass fraction, and caustic starch and collector FX-6Y are formulated into a 5% solution by mass fraction in a constant temperature box; the concentration of the pulp is controlled at 40% , the temperature is 20°C-25°C, the pH value is 9.0-10.0; sequentially add 650g / t sodium carbonate, 650g / t water glass, 200g / t aluminum sulfate, 1000g / t caustic starch, and 1050g / t collector FX-6Y , act for two minutes respectively;

[0046] b. Sweeping: The scavenging operation is carried out at a slurry concentration of 40%, a temperature of 20°C-25°C, and a pH value of 9.0-9.5, and the roughing tailings are swept for 2 minutes to...

Embodiment 2

[0059] Embodiment 2, comprises the following steps:

[0060] (1) Grinding operation:

[0061] The dolomite-type magnetite magnetic separation tailings are further finely ground to -0.074mm, accounting for 94.54%;

[0062] (2) Flotation operation:

[0063] a. Rough selection: Sodium carbonate, water glass, and aluminum sulfate are formulated into a 5% solution by mass fraction, and caustic starch and collector FX-6Y are formulated into a 5% solution by mass fraction in a constant temperature box; the concentration of the pulp is controlled at 40% , the temperature is 20°C-25°C, the pH value is 9.0-10.0; sequentially add sodium carbonate 700g / t, water glass 650g / t, aluminum sulfate 150g / t, caustic starch 900g / t, collector FX-6Y 1000g / t , act for two minutes respectively;

[0064] b. Sweeping: The scavenging operation is carried out at a slurry concentration of 40%, a temperature of 20°C-25°C, and a pH value of 9.0-9.5, and the roughing tailings are swept for 2 minutes to obta...

Embodiment 3

[0077] Embodiment 3, comprises the following steps:

[0078] (1) Grinding operation:

[0079] The dolomite-type magnetite magnetic separation tailings are further finely ground to -0.074mm, accounting for 92.10%-96.10%;

[0080] (2) Flotation operation:

[0081] a. Rough selection: Sodium carbonate, water glass, and aluminum sulfate are formulated into a 5% solution by mass fraction, and caustic starch and collector FX-6Y are formulated into a 5% solution by mass fraction in a constant temperature box; the concentration of the pulp is controlled at 40% -45%, the temperature is 20°C-25°C, the pH value is 9.0-10.0; add sodium carbonate 700g / t, water glass 600g / t, aluminum sulfate 150g / t, caustic starch 1000g / t, collector FX- 6Y1000g / t, act for two minutes respectively;

[0082] b. Sweeping: Sweeping operation is carried out at a slurry concentration of 42%, a temperature of 20°C-25°C, and a pH value of 9.0-9.5. The roughing tailings are swept for 2 minutes to obtain the scave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com