A wire drawing machine device for processing titanium alloy wire

A technology of titanium alloy wire and wire drawing machine, which is applied in the direction of metal processing, metal processing equipment, metal extrusion cleaning equipment, etc., can solve the impact of finished product quality of titanium alloy wire, high processing environment area requirements, titanium alloy wire Damage and other problems, to achieve significant lubrication effect, good protection effect, and improve the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, so as to better reflect the advantages of the present invention.

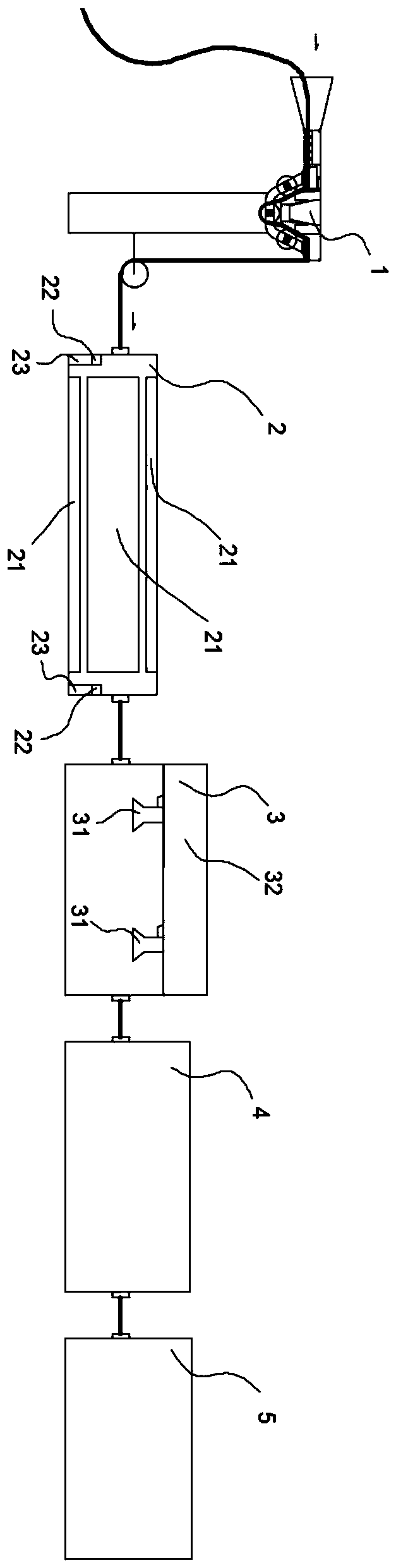

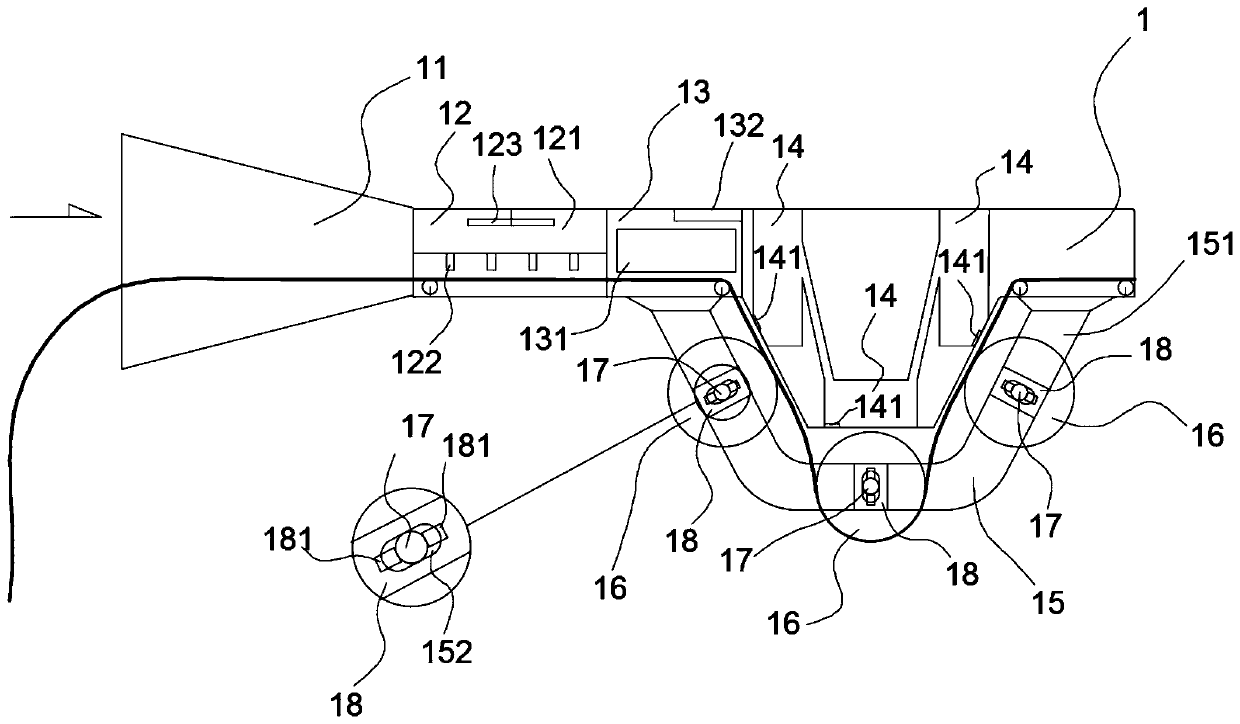

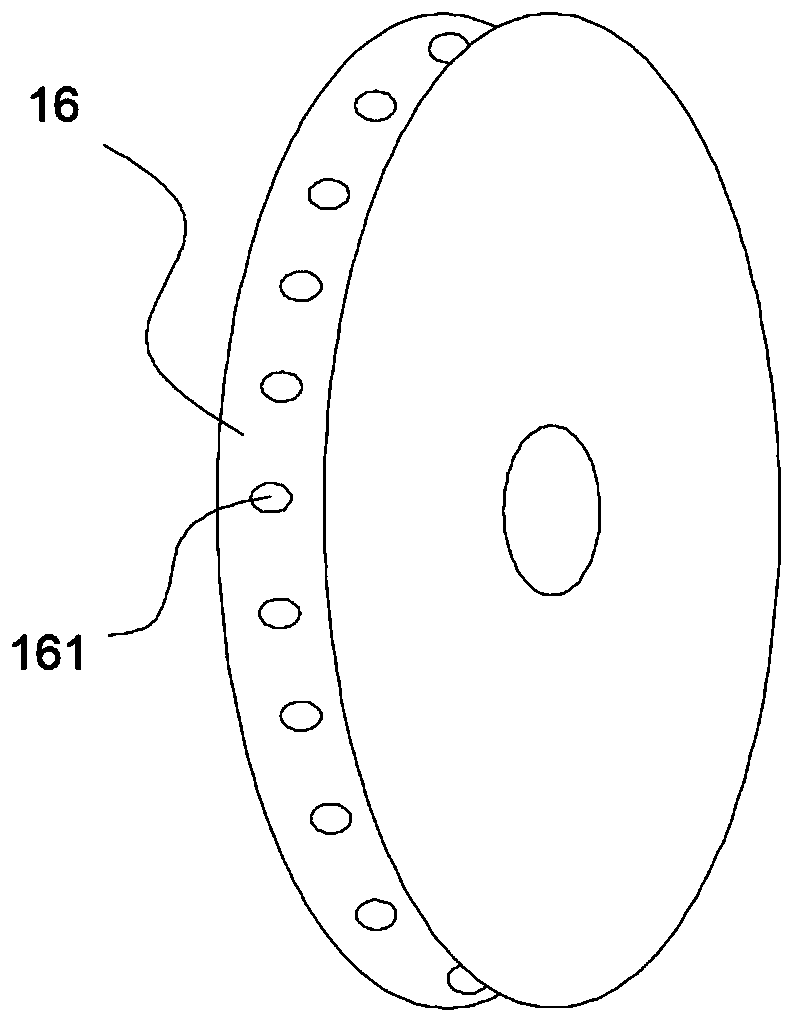

[0026] Such as Figure 1-3 As shown, a wire drawing machine device for processing titanium alloy wire, the wire drawing machine device is composed of a multifunctional processing device 1, a wire drawing device 2, a cleaning device 3, an annealing device 4 and a wire receiving device 5, and the multifunctional processing device 1 , wire drawing device 2, cleaning device 3, annealing device 4 and wire receiving device 5 are all modular devices that can operate independently. 1. It is composed of intelligent wire wheel set 15, wire coating module A 12, drying module 13 and wire coating module B 14. On the left side of the drying module 13, the intelligent guiding wheel 15 is positioned under the silk coating module A 12, the drying module 13 and the silk coating module B14, and the intelligent guiding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com