Microfluidics preparation technology for monodisperse gold nanoparticles with controllable size

A gold nanoparticle, monodisperse technology, applied in the direction of nanotechnology, can solve the problems of poor corrosion resistance, unfavorable nanoparticles, precise controllability, etc., and achieve the effect of stable solution mixing, high device flexibility, and uniform reaction mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

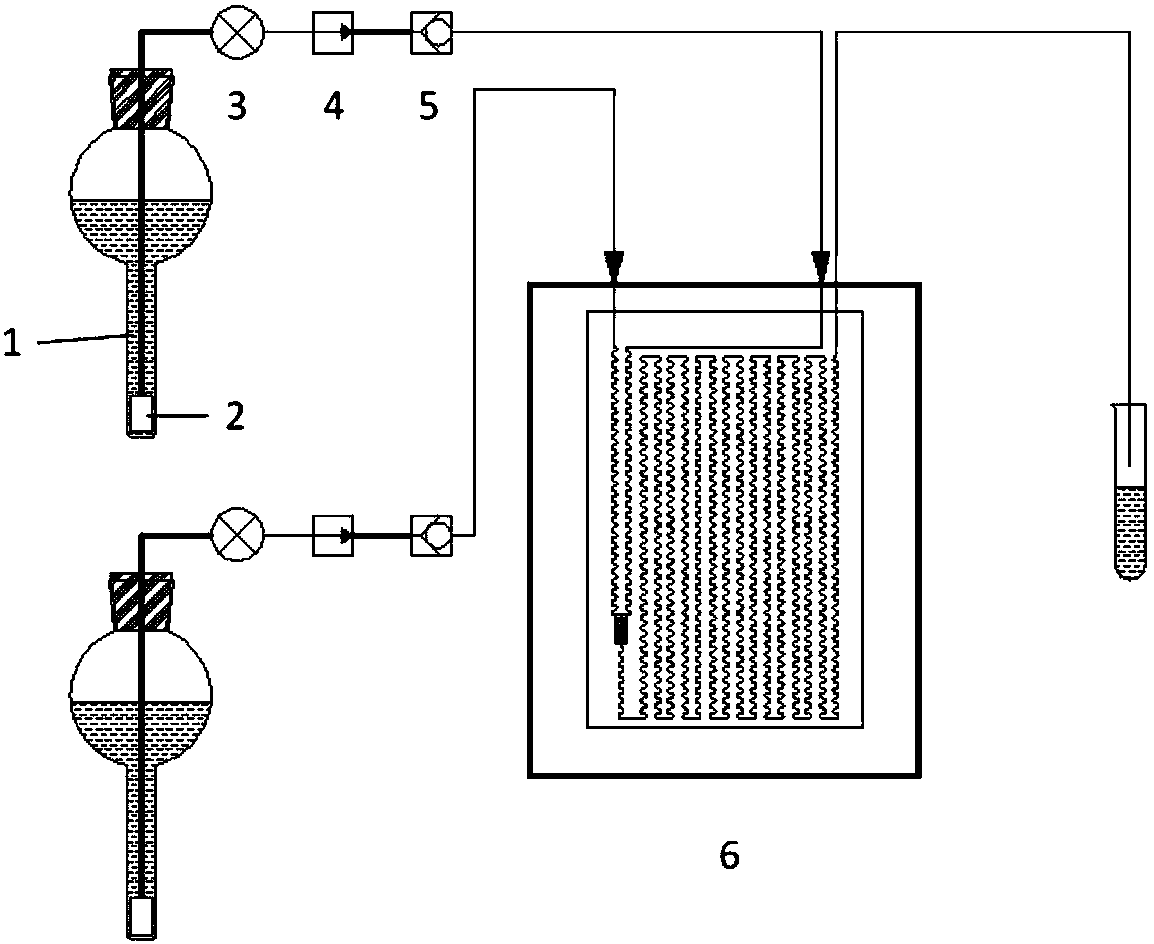

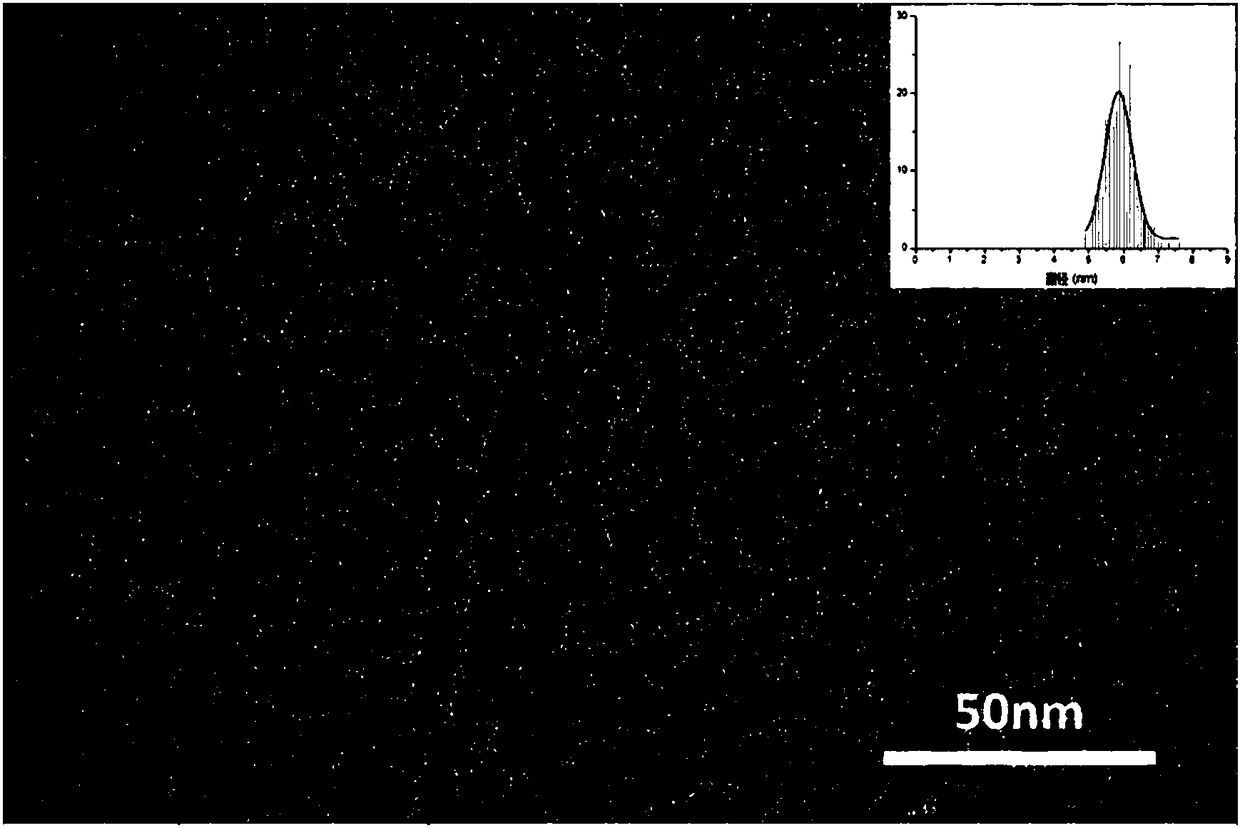

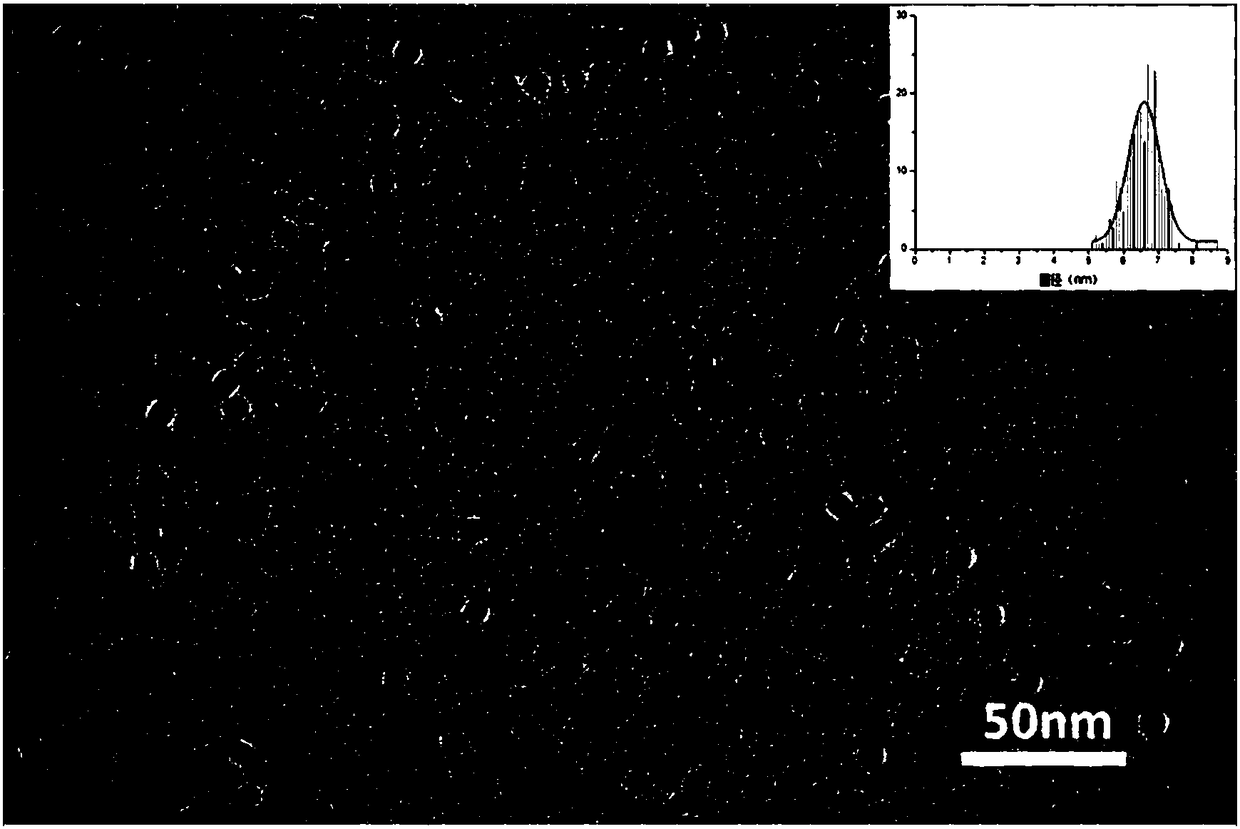

[0031] The microfluidic preparation technology of a size-controllable monodisperse gold nanoparticle provided by the present invention, in terms of steps, is mainly divided into the acquisition of the gold nanoparticle reaction precursor solution based on the traditional preparation method with a micro-reaction device, The reaction precursor is transferred to the microfluidic system, and the controllable parameters of the microfluidic device are continuously controllable to prepare and obtain a uniform monodisperse gold nanoparticle toluene solution, and finally obtain monodisperse gold nanoparticles of different sizes corresponding to different flow rates (reaction time) . Concrete steps of the present invention are as follows:

[0032] Step 1, constructing a micro-reaction system based on the gold particle preparation method.

[0033] Step 2, obtaining the gold nanoparticle reaction precursor.

[0034] The unit millimolar amount of triphenylphosphorus gold chloride was dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com