Machining center tool failure preventing system

A fault prevention, machining center technology, applied in wood processing appliances, manufacturing tools, circular saws, etc., can solve the problem of not being able to prevent tool wear and chip removal in time, and achieve the purpose of preventing wear, increasing gas discharge, and improving grinding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

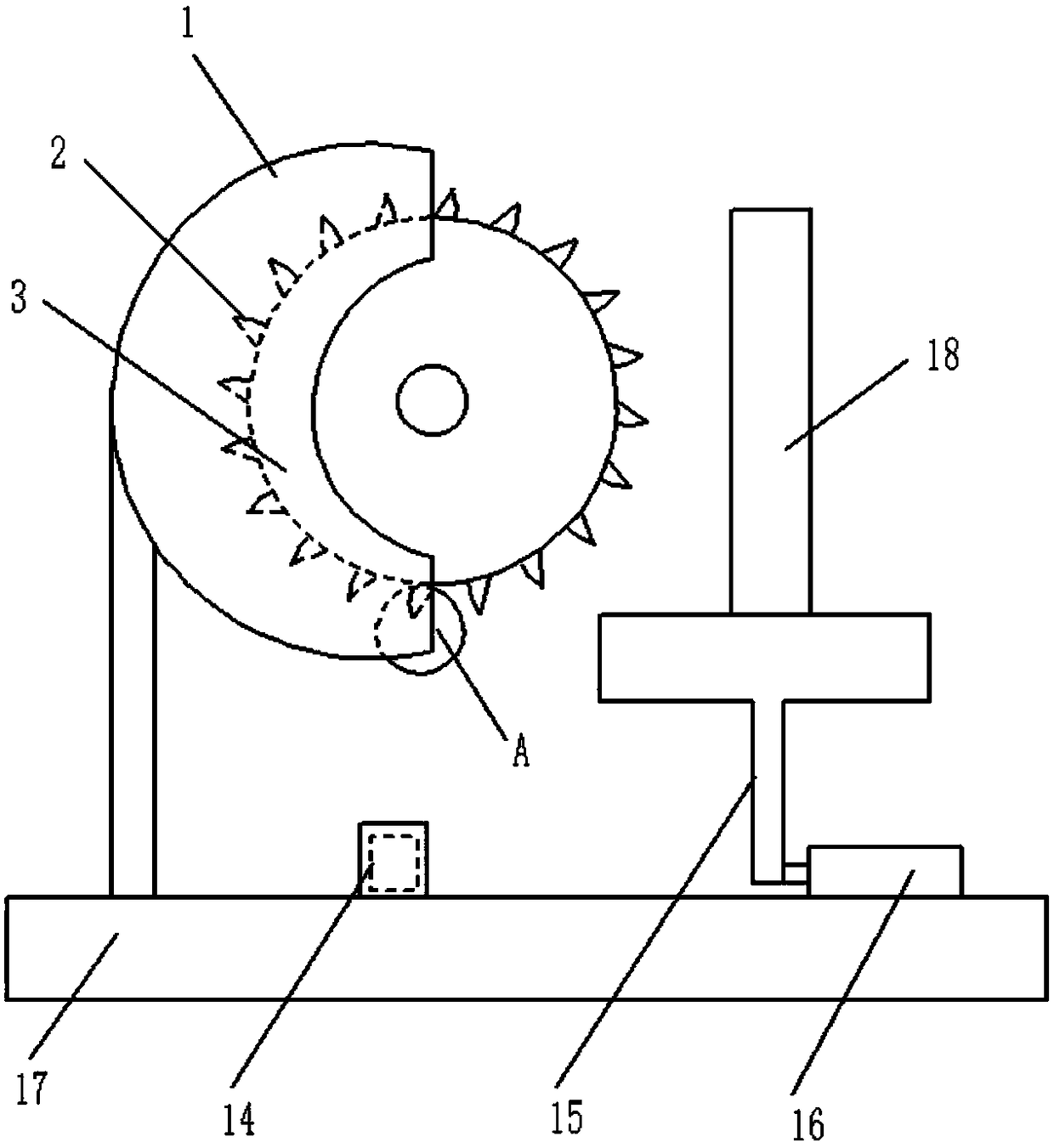

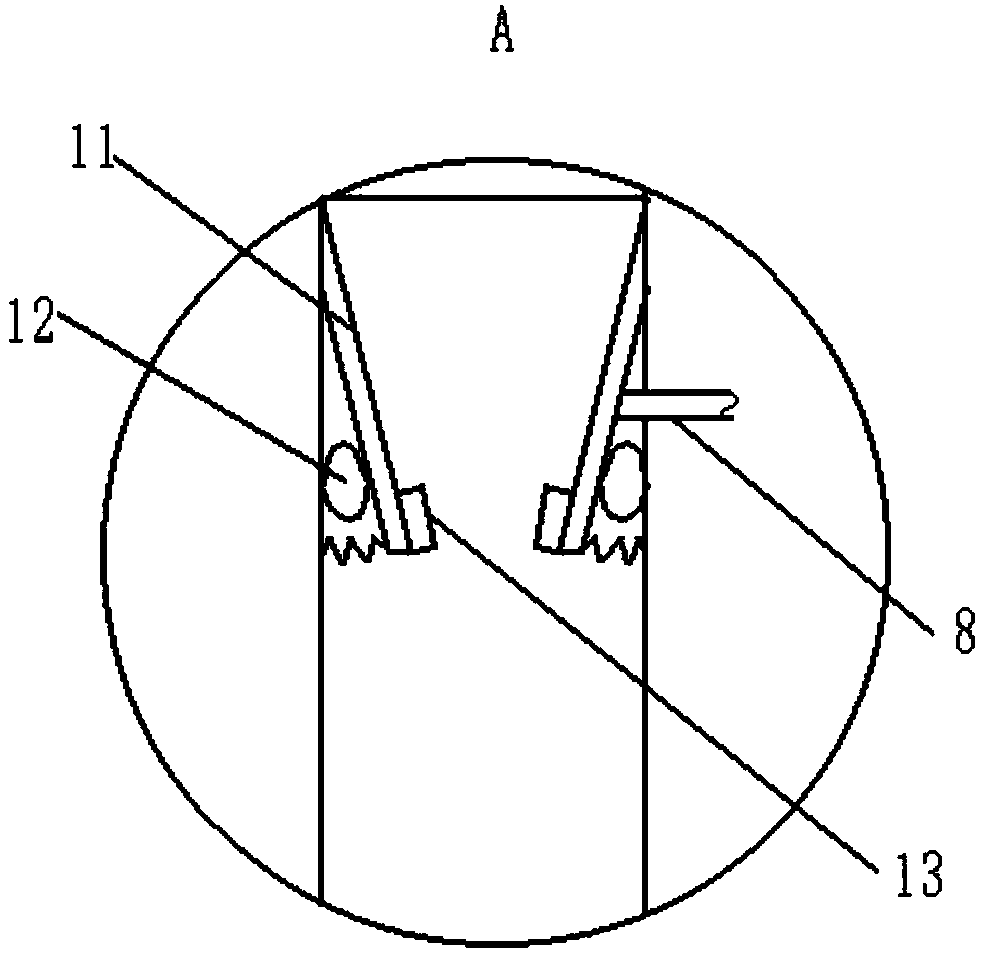

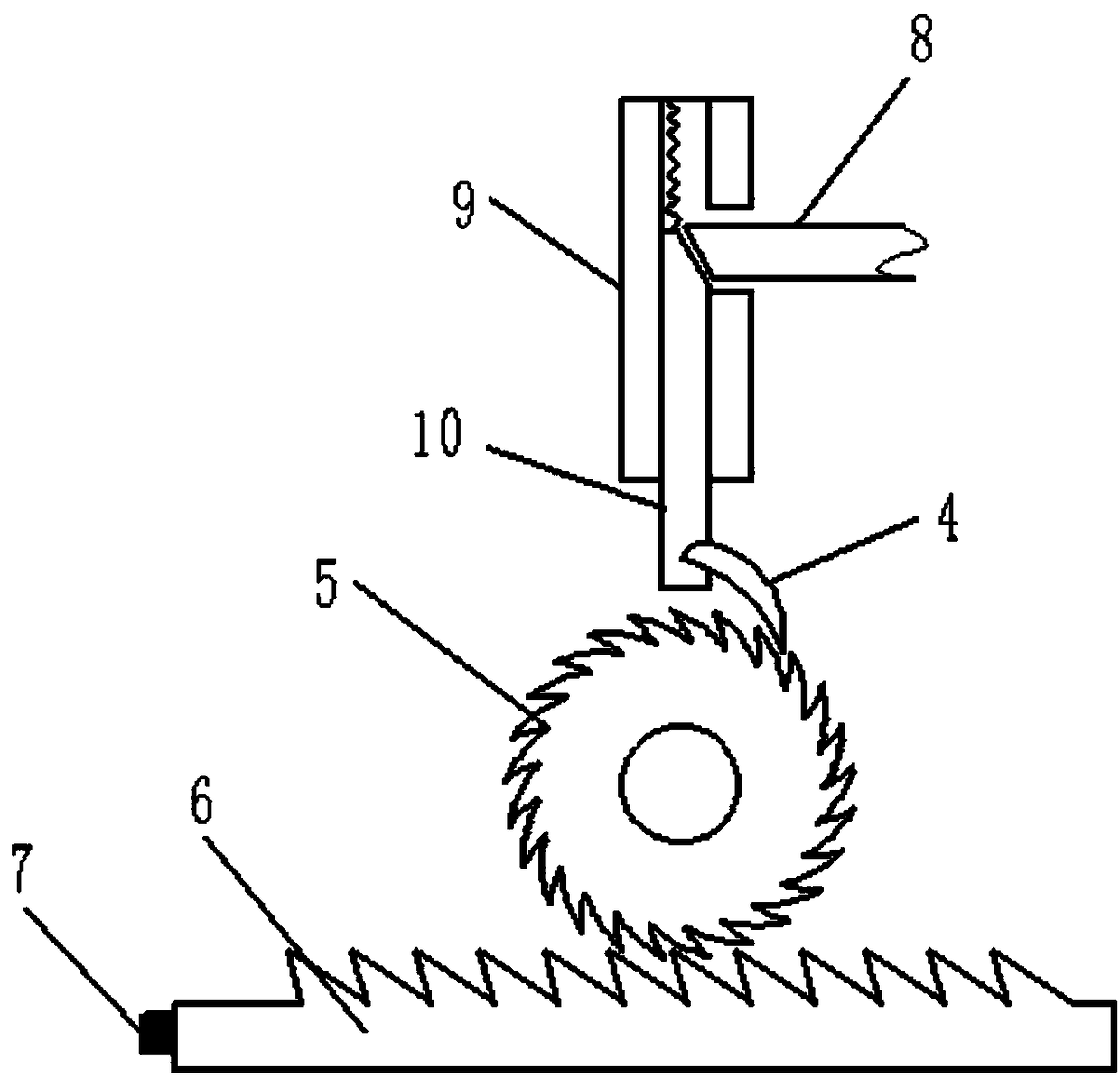

[0025] The reference signs in the drawings of the description include: housing 1, saw blade 2, disc 3, pawl 4, ratchet 5, rack 6, pressure block 7, push rod 8, guide rail 9, slide rod 10, pressure plate 11, Air bag 12, polishing block 13, normally closed switch 14, material placement platform 15, cylinder 16, processing platform 17, timber 18.

[0026] Such as figure 1 Shown: the tool failure prevention system of the machining center includes a machining table 17 and a circular saw. The machining table 17 is also provided with a material placement table 15, a cylinder 16, a normally closed switch 14 and a controller (not shown in the figure), and the cylinder The output shaft of 16 connects the material table 15, and the cylinder 16 can drive the material table 15 to move towards the circular saw direction, and the normally closed switch 14 circuits are connected to the controller. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com