Subzero treatment process of TC6 titanium alloy forge piece

A cryogenic treatment and titanium alloy technology, applied in the field of cryogenic treatment process, can solve the problems affecting the comprehensive mechanical properties of materials, not considering thermal stress, poor structure, etc., to maintain mechanical stability, improve uniformity and stability, and increase strength and plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

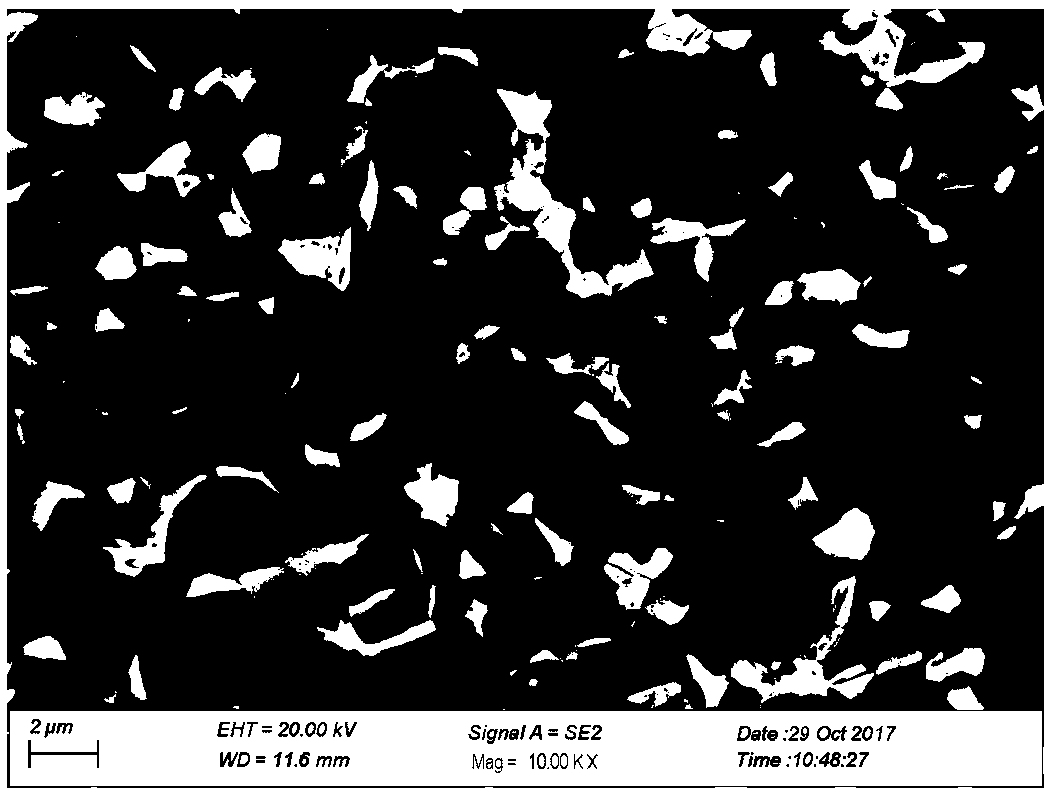

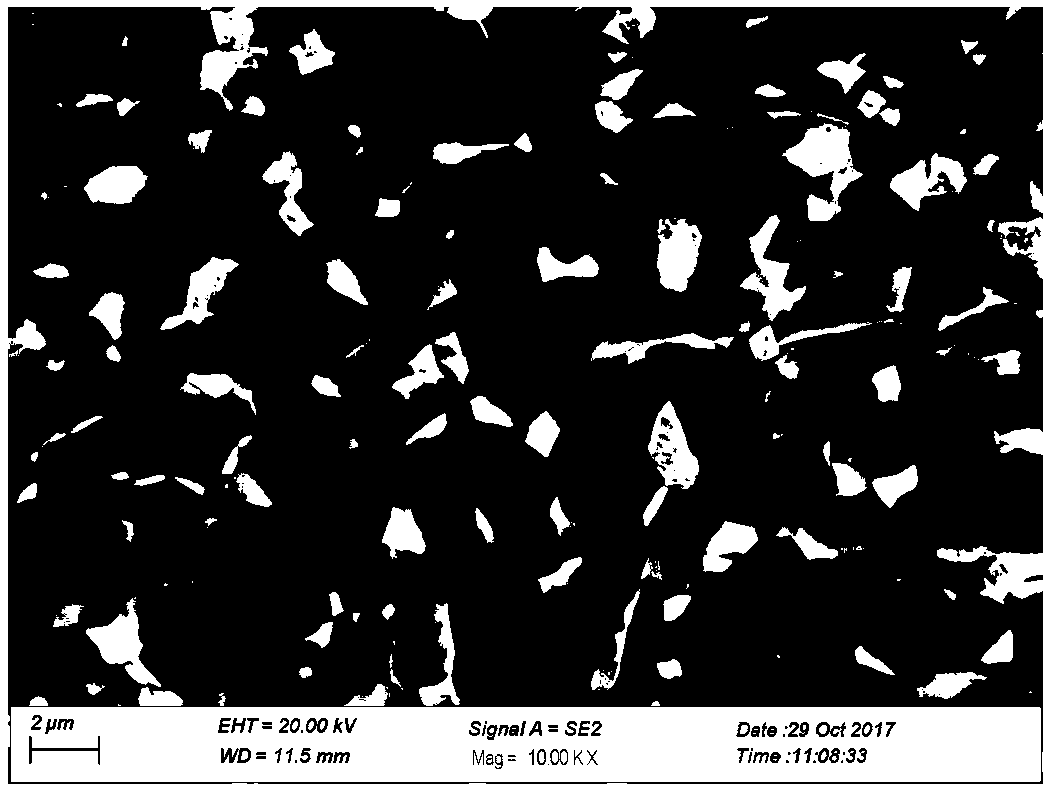

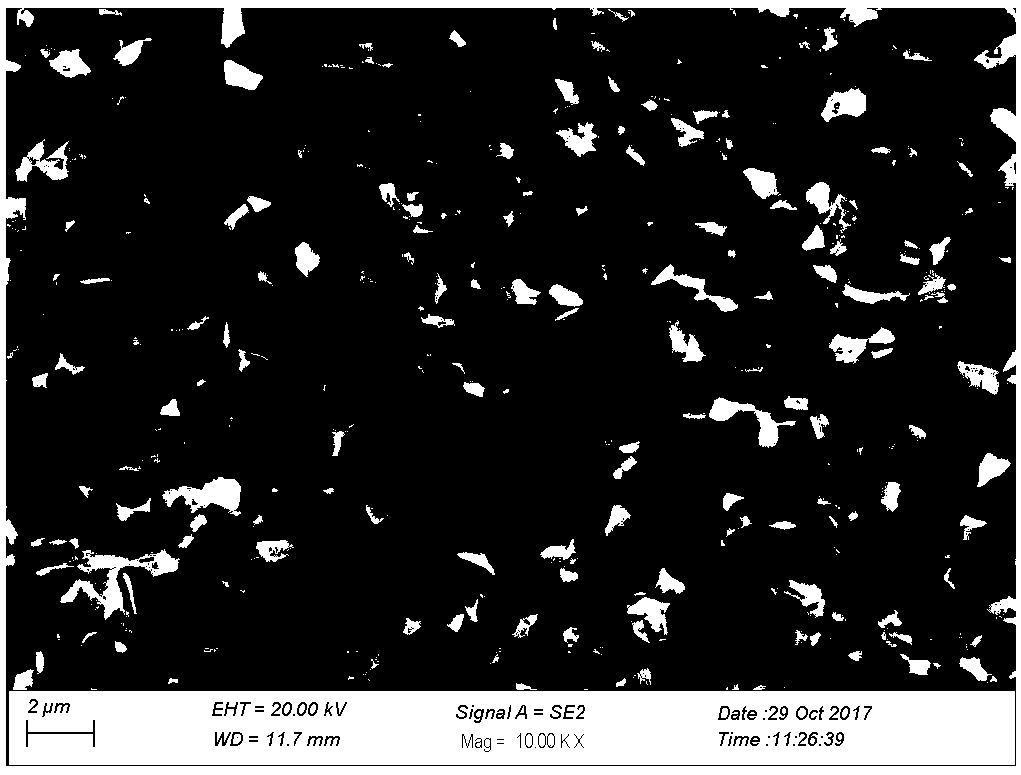

Image

Examples

Embodiment 1

[0023] Step 1: Forging: Put the TC6 titanium alloy bar into the heating furnace and heat it to 1080°C. After holding it for 2 hours, use a hydraulic press to perform axial upsetting, then perform radial drawing and chamfering, and finally perform rounding and upsetting to reach size requested.

[0024] Step 2: heat treatment: solution treatment is carried out on the forged TC6 titanium alloy, the heating temperature is 900 ° C, water quenching is carried out immediately after heat preservation for 3 hours, and after solution treatment; then double annealing treatment is performed, and the double annealing is two low temperature annealings , the first annealing: put the plate obtained in the second step into the heating furnace, raise the temperature of the heating furnace to 820°C at a heating rate of 200°C / h, keep it warm for 3h after soaking, and then air cool for 2h; the second annealing: put the first After the first annealing, the plate is reheated to 640°C with a heating...

Embodiment 2

[0028] Step 1: Forging: Put the TC6 titanium alloy bar into the heating furnace and heat it to 1080°C. After holding it for 2 hours, use a hydraulic press to perform axial upsetting, then perform radial drawing and chamfering, and finally perform rounding and upsetting to reach size requested.

[0029] Step 2: heat treatment: solution treatment is carried out on the forged TC6 titanium alloy, the heating temperature is 900 ° C, water quenching is carried out immediately after heat preservation for 3 hours, and after solution treatment; then double annealing treatment is performed, and the double annealing is two low temperature annealings , the first annealing: put the plate obtained in the second step into the heating furnace, raise the temperature of the heating furnace to 840°C at a heating rate of 200°C / h, keep it warm for 3h after soaking, and then air cool for 2h; the second annealing: put the first After primary annealing, the plate was reheated to 660°C with a heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com