Preparation method of high-melting-point metal wire

A high-melting-point metal and metal wire technology, applied in the field of material processing, can solve problems such as overheating and heating, and achieve the effects of stable processing technology, consistent temperature, and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment adopts iridium wire, iridium wire diameter 0.5mm, wire drawing section shrinkage ratio 19%, diameter 0.45mm after drawing: wire material moving speed 0.2 meter per second, when heating current I t When it is 2.7A, Vt=8.2mV, the wire reaches the drawing die temperature of 1100°C.

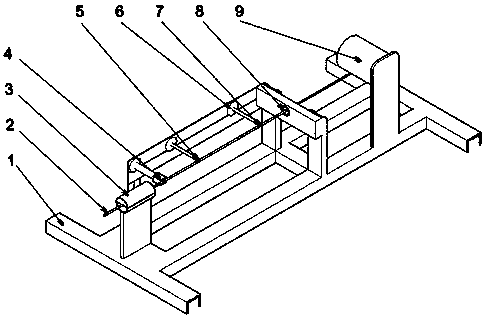

[0024] The wire 2 passes through the tension mechanism 3 and the wire drawing die 8 in turn, and is taken up by the wire drawing wheel 9. The wire 2 is wound on the wire drawing wheel 9, and the wire 2 is rotated to make the wire 2 pass through the wire drawing die 8 to achieve wire drawing and finally obtain a metal Silk;

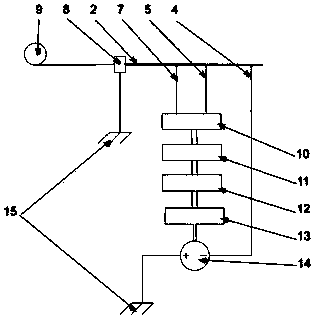

[0025] During the wire drawing process: the wire material 2 is in contact with the brush 4 and the wire drawing die 8, one end of the power supply 14 is connected with the brush 4, the other end is connected with the bracket 1, the wire drawing die 8 is installed on the bracket 1, and the wire drawing die 8 is in contact with the bracket 1 conductio...

Embodiment 2

[0031] The method described in this embodiment is the same as that in Embodiment 1, except that the wire 2, the brush 4, the front contact 5, and the rear contact 7 are placed in a closed environment, and the closed environment is evacuated or filled with an inert gas, thereby realizing Drawing process under vacuum or atmosphere protection.

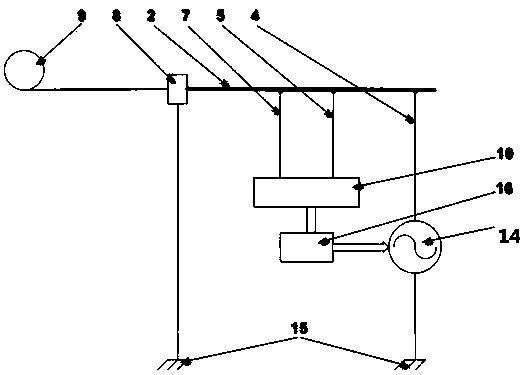

[0032] The power supply 14 in this embodiment is an AC power supply, which is characterized by a stable current and an adjustable power supply, and the voltage measured between the front contact 5 and the rear contact 7 is an AC signal.

[0033] In this embodiment, the control method is analog control, and the specific process is: a front contact 5 and a rear contact 7 that are in contact with the wire 2 are provided in the heating section of the wire 2, and the front contact 5 and the rear contact 7 are measured. The potential value between the points 7, the output terminals of the front contact 5 and the rear contact 7 are connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com