A high-precision hydraulic synchronization system, a jack-raising control method and a section-increasing height increasing method for section-increasing height increasing of a large-scale crane

A hydraulic synchronous jacking, high-precision technology, used in lifting devices, transportation and packaging, load hanging components, etc., can solve the problem of interfering with proportional directional valve flow control, unable to monitor the actual bearing capacity of the jacking cylinder, affecting the jacking cylinder And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

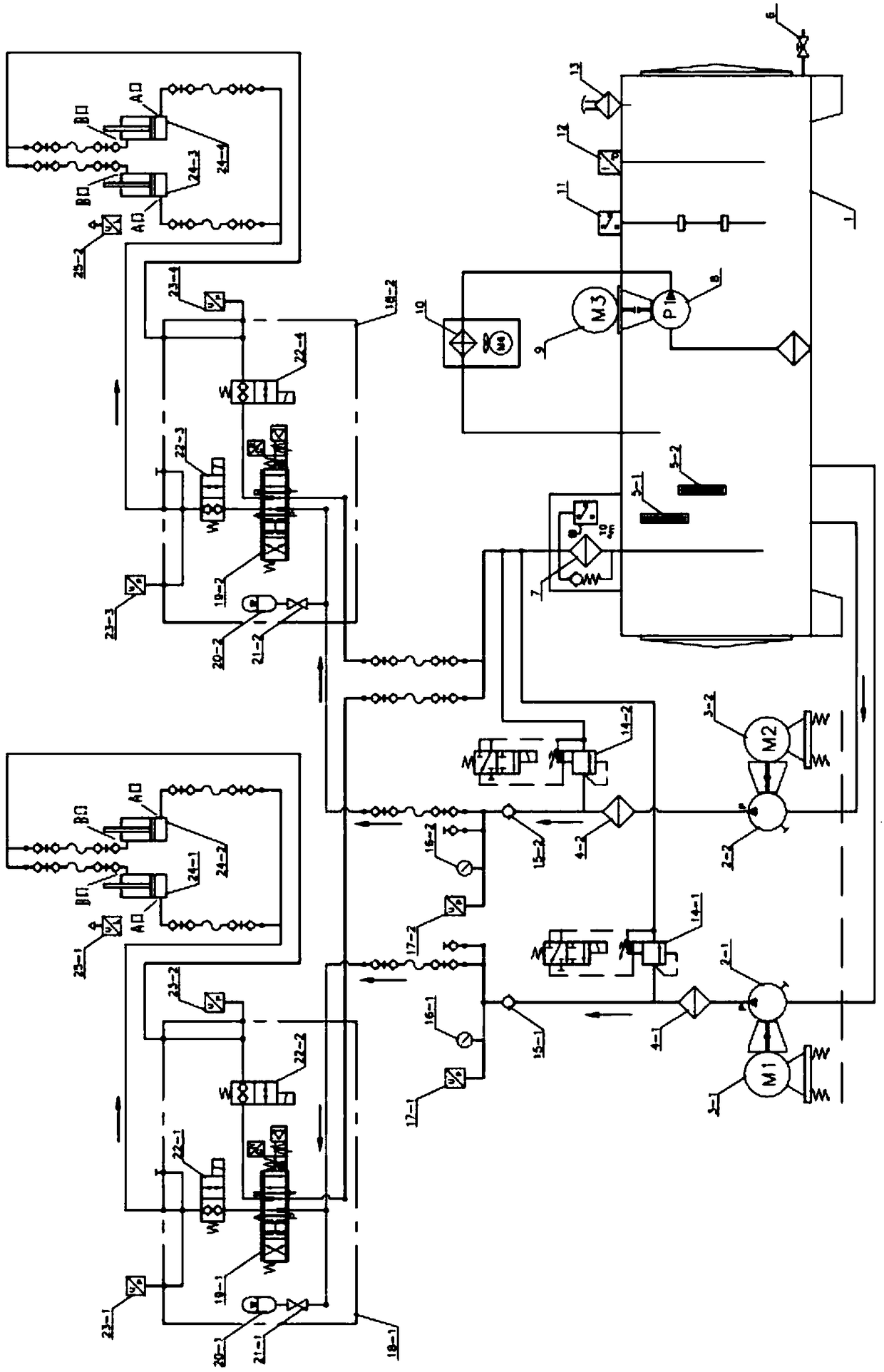

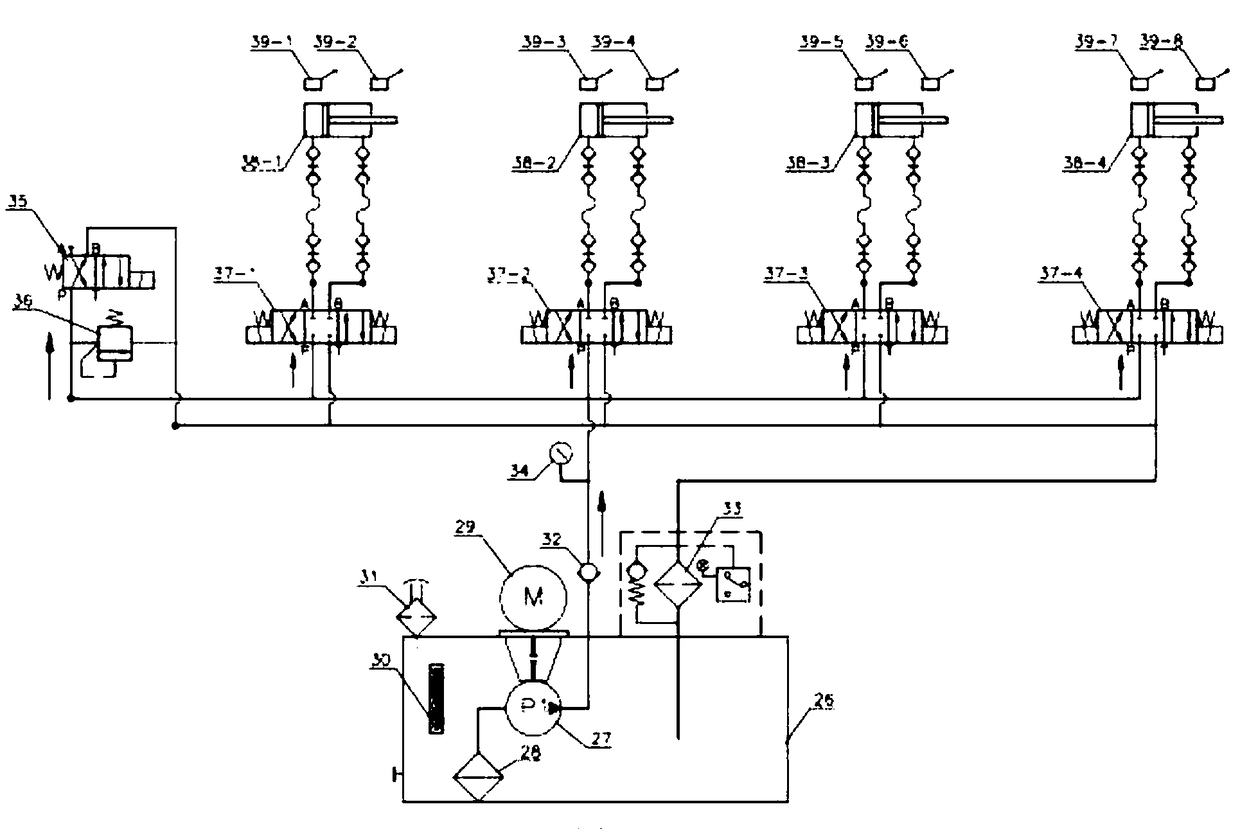

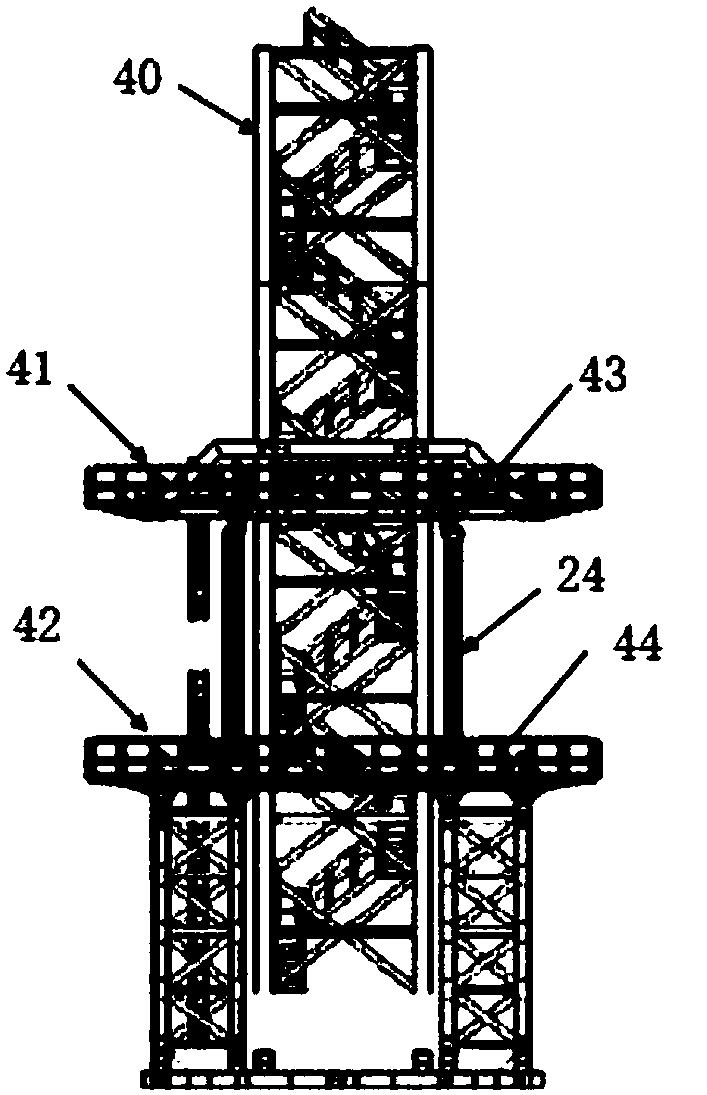

[0052] Such as image 3 As shown, the present invention is a high-precision hydraulic synchronous jacking system for large-scale tower cranes, which includes a load-bearing platform, a jacking device, a horizontal bolt device, a console, a programmable logic controller (PLC controller) , servo motion controller; jacking device comprises jacking oil cylinder 24, the jacking hydraulic system that is connected with jacking oil cylinder; group, that is, the upper horizontal latch device and the lower horizontal latch device; the load-bearing platform is a hollow structure, and the tower crane 40 (assembled standard section) is placed in the middle; the load-bearing platform is divided into upper and lower layers, that is, the upper load-bearing platform 41, the lower Power platform 42; The lower bearing platform 42 is provided with a vertically placed jacking oil cylinder 24, a horizontal lower horizontal oil cylinder 39, and a lower horizontal latch 44 connected with the piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com