Construction mode of power cable

A technology of power cables and cable sleeves, which is applied in the field of power cables, and can solve the problems that power cables cannot adapt to Martin's thermal stability and high Vicat softening point requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

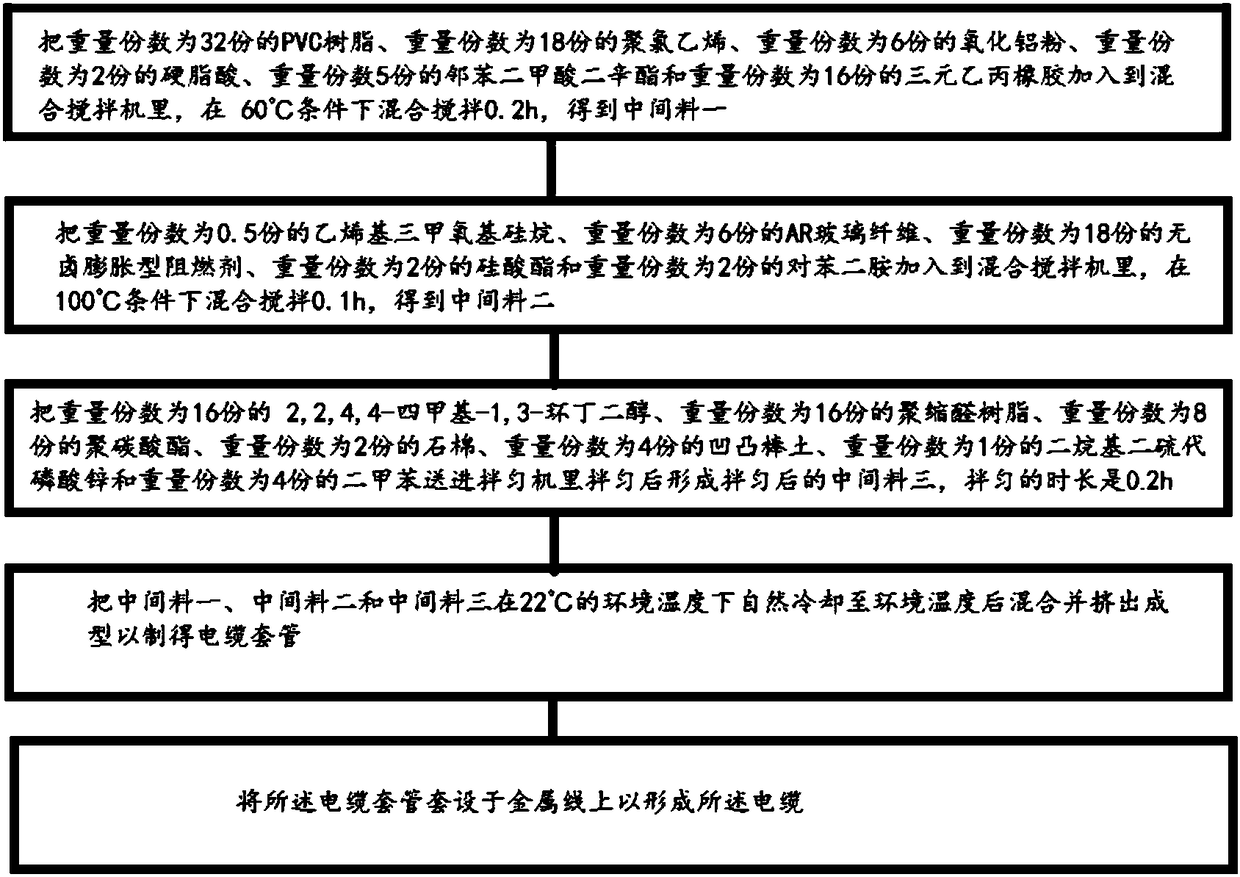

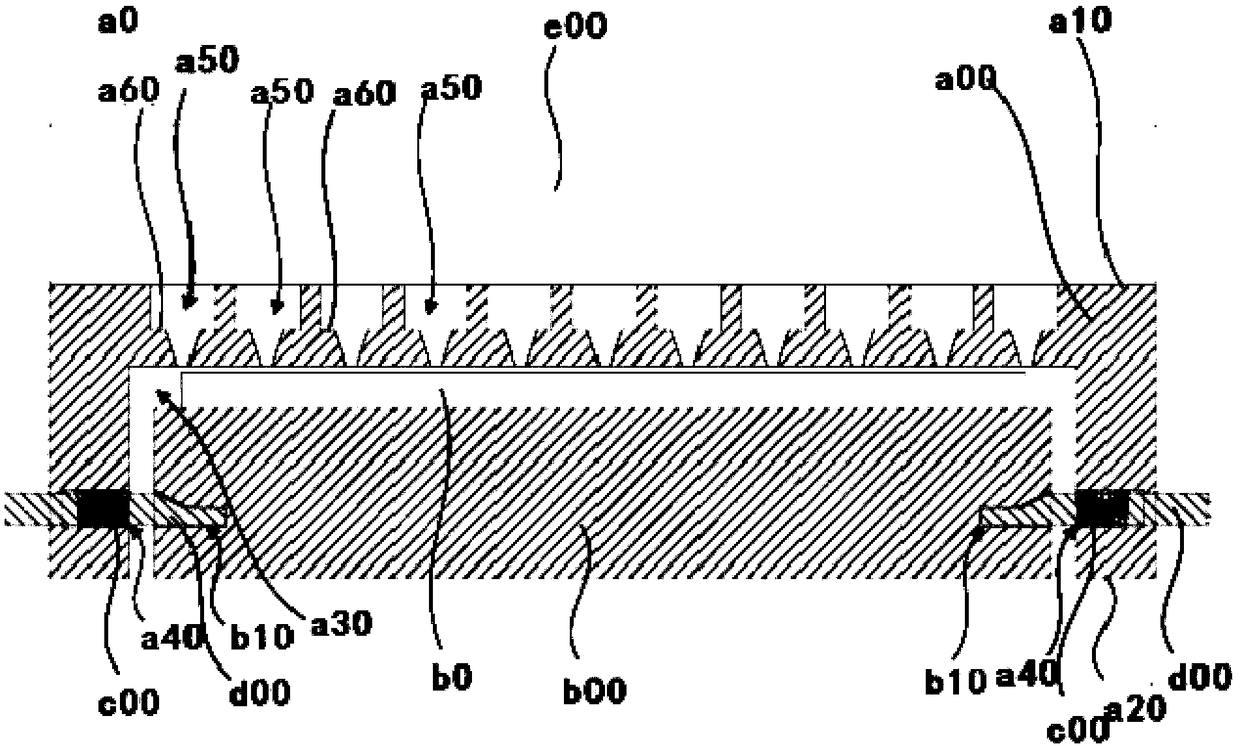

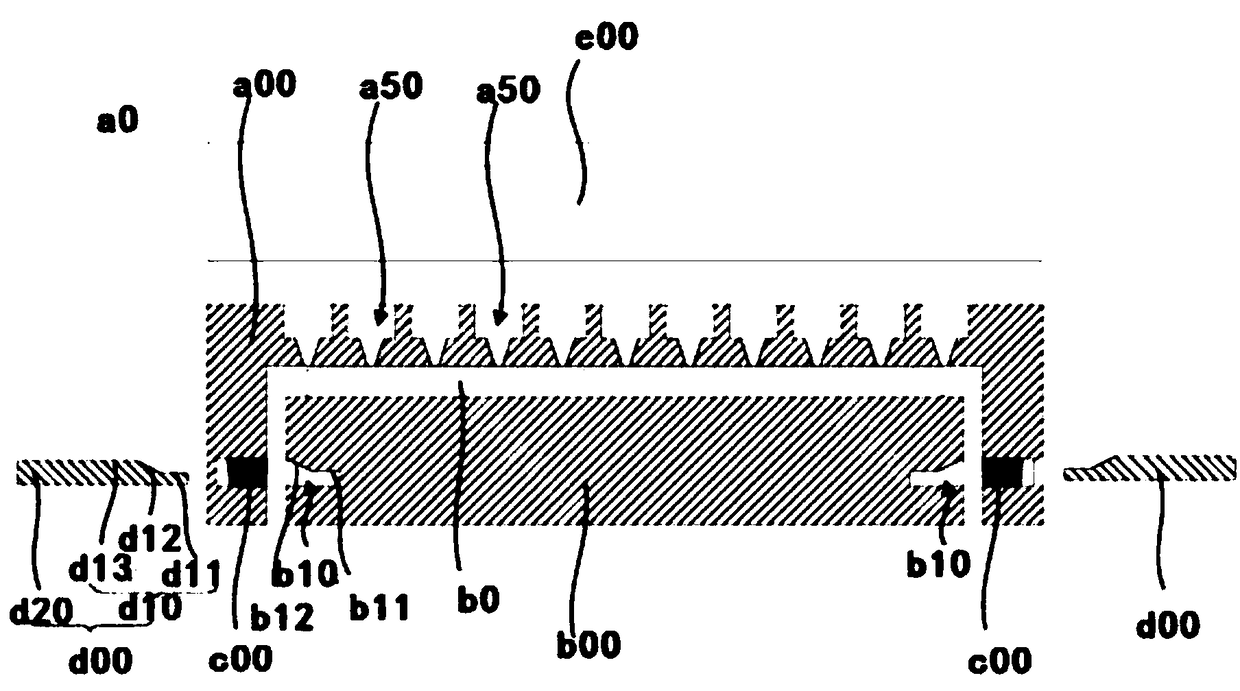

[0048] Such as Figure 1-Figure 5 As shown, the construction method of the power cable includes the following steps:

[0049] Step a, the parts by weight are 32 parts of PVC resin, the polyvinyl chloride of 18 parts by weight, the aluminum oxide powder of 6 parts by weight, the stearic acid of 2 parts by weight, the parts by weight 5 parts of dioctyl phthalate and 16 parts by weight of EPDM rubber were added to the mixing mixer, and mixed and stirred at 60°C for 0.2h to obtain intermediate material 1;

[0050] Step b, 0.5 parts by weight of vinyltrimethoxysilane, 6 parts by weight of AR glass fiber, 18 parts by weight of halogen-free intumescent flame retardant, 2 parts by weight Silicate and 2 parts by weight of p-phenylenediamine were added into the mixing mixer, and mixed and stirred at 100°C for 0.1h to obtain intermediate material 2;

[0051] Step c, 16 parts by weight of 2,2,4,4-tetramethyl-1,3-cyclobutanediol, 16 parts by weight of polyacetal resin, 8 parts by weight ...

Embodiment 2

[0083] The construction method of the power cable includes the following steps:

[0084] Step a, the parts by weight are 40 parts of PVC resin, the polyvinyl chloride of 23 parts by weight, the aluminum oxide powder of 9 parts by weight, the stearic acid of 3 parts by weight, the parts by weight Add 6 parts of dioctyl phthalate and 20 parts by weight of EPDM rubber into the mixing mixer, and mix and stir at 75°C for 0.4h to obtain intermediate material 1;

[0085] Step b, taking 1 part by weight of vinyltrimethoxysilane, 9 parts by weight of AR glass fiber, 19 parts by weight of halogen-free intumescent flame retardant, 3 parts by weight Silicate and 3 parts by weight of p-phenylenediamine were added to the mixing mixer, and mixed and stirred at 110°C for 0.45h to obtain intermediate material 2;

[0086] Step c, the 2,2,4,4-tetramethyl-1,3-cyclobutanediol that is 20 parts by weight, the polyacetal resin that is 20 parts by weight, 9 parts by weight polycarbonate, 4 parts by ...

Embodiment 3

[0120] Cable material, the cable material includes: the material includes: 48 parts by weight of PVC resin, 28 parts by weight of polyvinyl chloride, 12 parts by weight of alumina powder, 4 parts of stearic acid, dioctyl phthalate of 7 parts by weight, EPDM rubber of 24 parts by weight, vinyltrimethoxysilane of 1.5 parts by weight, parts by weight 12 parts by weight of AR glass fiber, 20 parts by weight of halogen-free intumescent flame retardant, 4 parts by weight of silicate and 4 parts by weight of p-phenylenediamine;

[0121] The material also includes: 2,2,4,4-tetramethyl-1,3-cyclobutanediol in parts by weight, polyacetal resin in parts by weight, parts by weight in 10 parts of polycarbonate, 6 parts of asbestos, 10 parts of attapulgite, 3 parts of zinc dialkyldithiophosphate and 6 parts of xylene.

[0122] The construction method of the power cable comprises the steps of:

[0123] Step a, be the PVC resin of 48 parts by weight, the polyvinyl chloride that is 28 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com