Cementing material for colored pavement and manufacturing method thereof

A technology of colored pavement and manufacturing method, which is applied in the directions of roads, road repair, construction, etc., can solve the problems of unsatisfactory performance requirements of cementitious materials such as temperature sensitivity, rutting resistance and fission resistance, and achieve good water stability, The effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

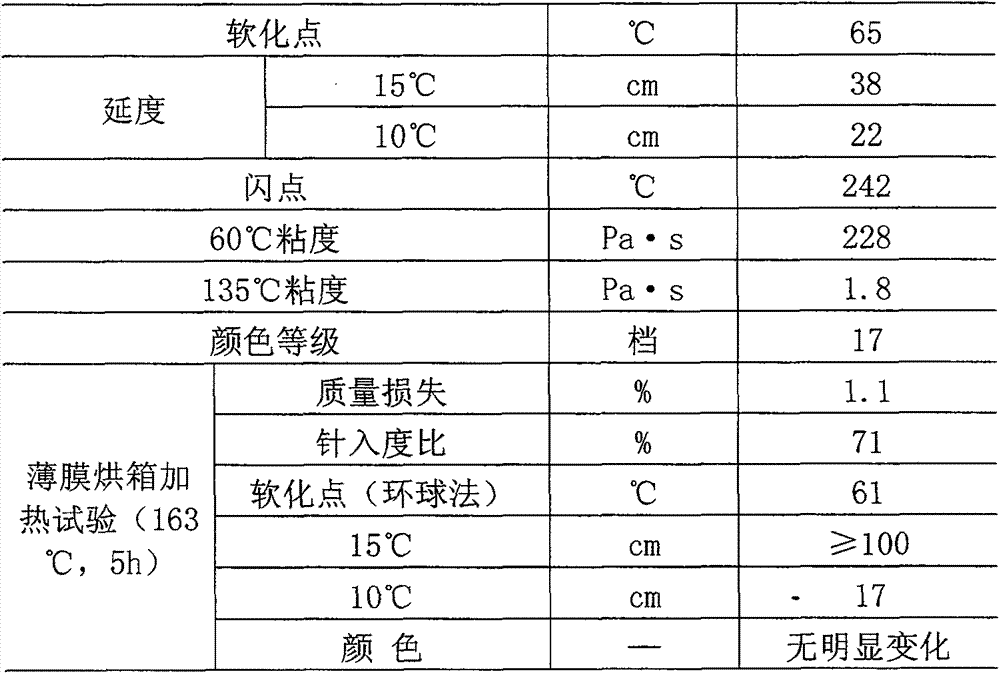

Method used

Image

Examples

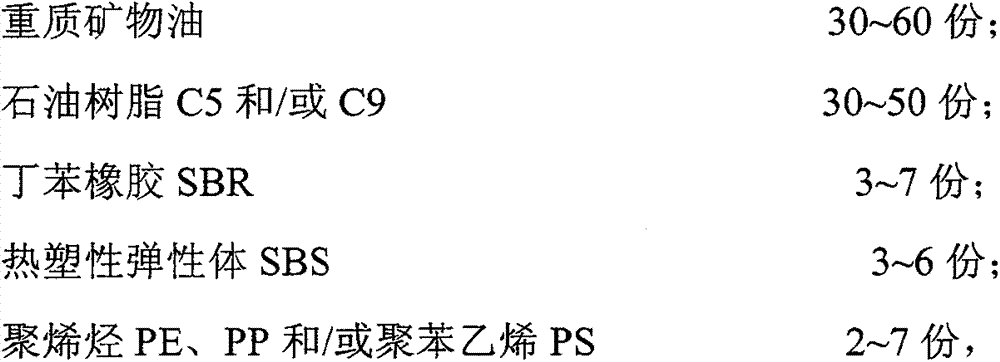

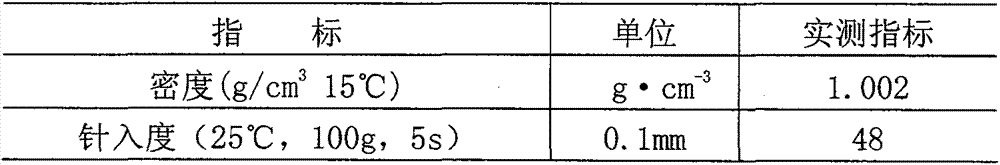

Embodiment 1

[0038] Prepare the reaction kettle, stir in the kettle at a low speed, the stirring speed is 100r / min, so that the added materials are fully mixed; add 550kg of heavy mineral oil to the kettle at room temperature; raise the temperature to 150°C, add 250kg of C5, 100kg of C9 Then raise the temperature to 150°C, add SBR40kg, SBS30kg, PE30kg; then raise the temperature to 180°C, add 10kg of anti-aging agent, 10kg of heat stabilizer and 10kg of ultraviolet stabilizer; The shearing speed is 3800r / min, the shearing time is 3 hours, and the heat preservation reaction is 4 hours; then use high-pressure vacuum to discharge the air bubbles in the cementitious material, and when the temperature drops to 130°C, 0P-50 hot-mixed hot-paved motorway color pavement is obtained. Cementing material, the performance indicators are shown in Table 1.

[0039] Table 1 Performance indicators of OP-50 hot-mixed hot-paved motorway colored pavement binder

[0040]

[0041]

Embodiment 2

[0043] Prepare the reaction kettle, stir in the kettle at a low speed, the stirring speed is 100r / min, so that the added materials are fully mixed; add 570kg of heavy mineral oil to the kettle at room temperature; raise the temperature to 150°C, add 200kg of C5, 130kg of C9 Then raise the temperature to 150°C, add SBR30kg, SBS35kg, PE35kg; then raise the temperature to 180°C, add 10kg of anti-aging agent, 10kg of heat stabilizer and 10kg of ultraviolet stabilizer; The shearing speed is 4000r / min, shearing for 3 hours, heat preservation reaction for 4 hours; then use high-pressure vacuum to discharge the air bubbles in the cementitious material, and when the temperature drops to 130°C, the 0P-70 hot-mixed and hot-paved non-motor vehicle road color pavement is obtained The cementing material is used, and the performance indicators are shown in Table 2.

[0044] Table 2 Performance indicators of OP-70 hot-mixed hot-paved non-motor vehicle road colored pavement binder performance ...

Embodiment 3

[0048]Prepare the reaction kettle, stir in the kettle at a low speed, and the stirring speed is 100r / min, so that the added materials are fully mixed; add 600kg of heavy mineral oil to the kettle at room temperature; raise the temperature to 150°C, add 200kg of C5, 100kg of C9 Then raise the temperature to 150°C, add SBR40kg, SBS40kg, PE20kg; then raise the temperature to 180°C, add 10kg of anti-aging agent, 10kg of heat stabilizer and 10kg of ultraviolet stabilizer; The shearing speed is 4200r / min, the shearing time is 3 hours, and the heat preservation reaction is 4 hours; then use high-pressure vacuum to discharge the air bubbles in the cementitious material, and when the temperature drops to 130°C, 0P-90 hot-mixed hot-paved motorway color pavement is obtained. Cementing materials, the performance indicators are shown in Table 3.

[0049] Table 3 Performance Index of OP-90 Hot Mix and Hot Pavement Binder for Color Pavement of Motorway

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com