Bi-component modified polyester resin thermosetting ink

A technology of modified polyester and polyester resin, which is applied in ink, household utensils, applications, etc. It can solve the problems of poor leveling, high product defect rate, and difficulty in reaching customers, and achieve good leveling, excellent Adhesive, high hiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples describe in further detail specific embodiments of the present invention. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

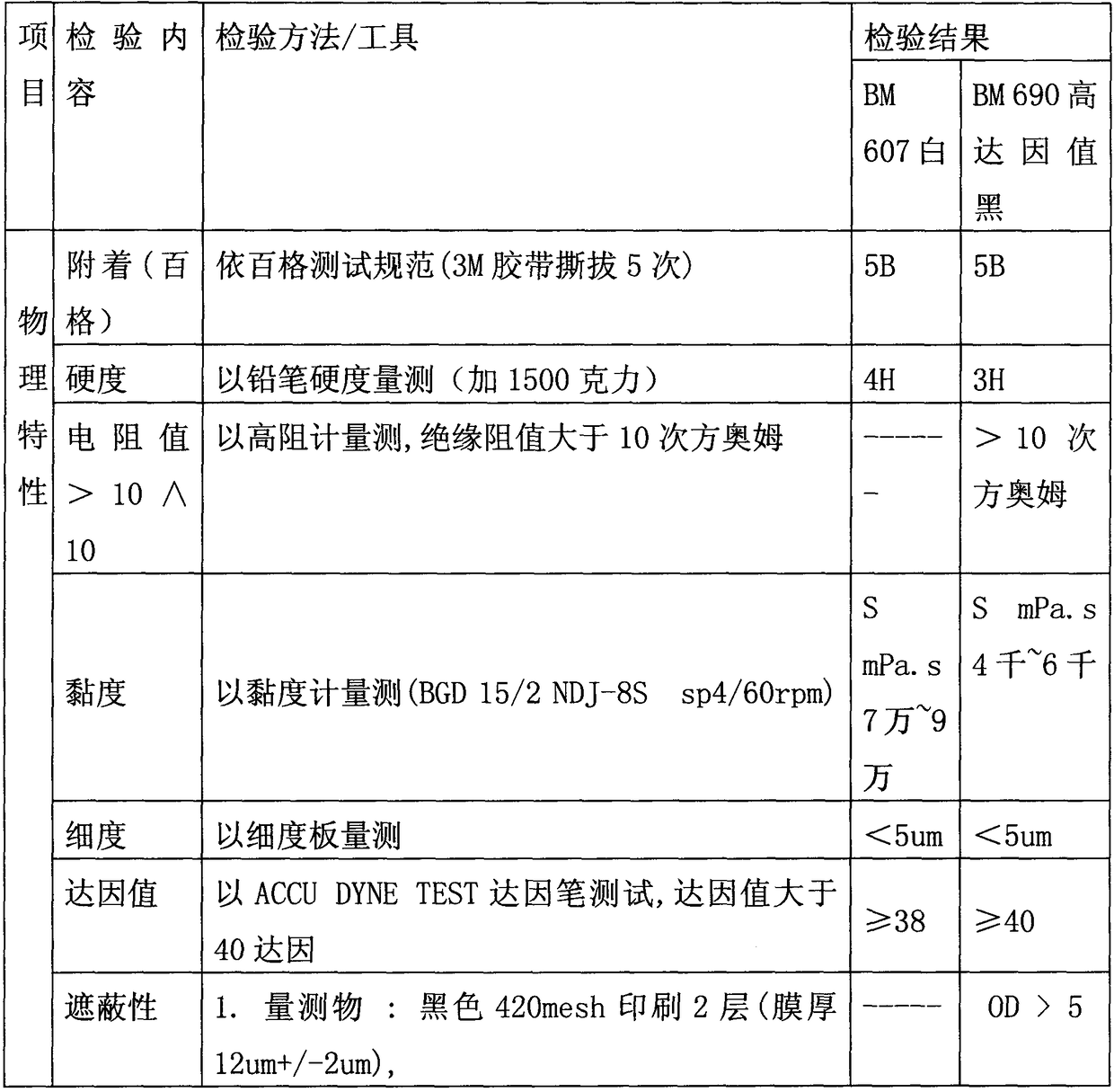

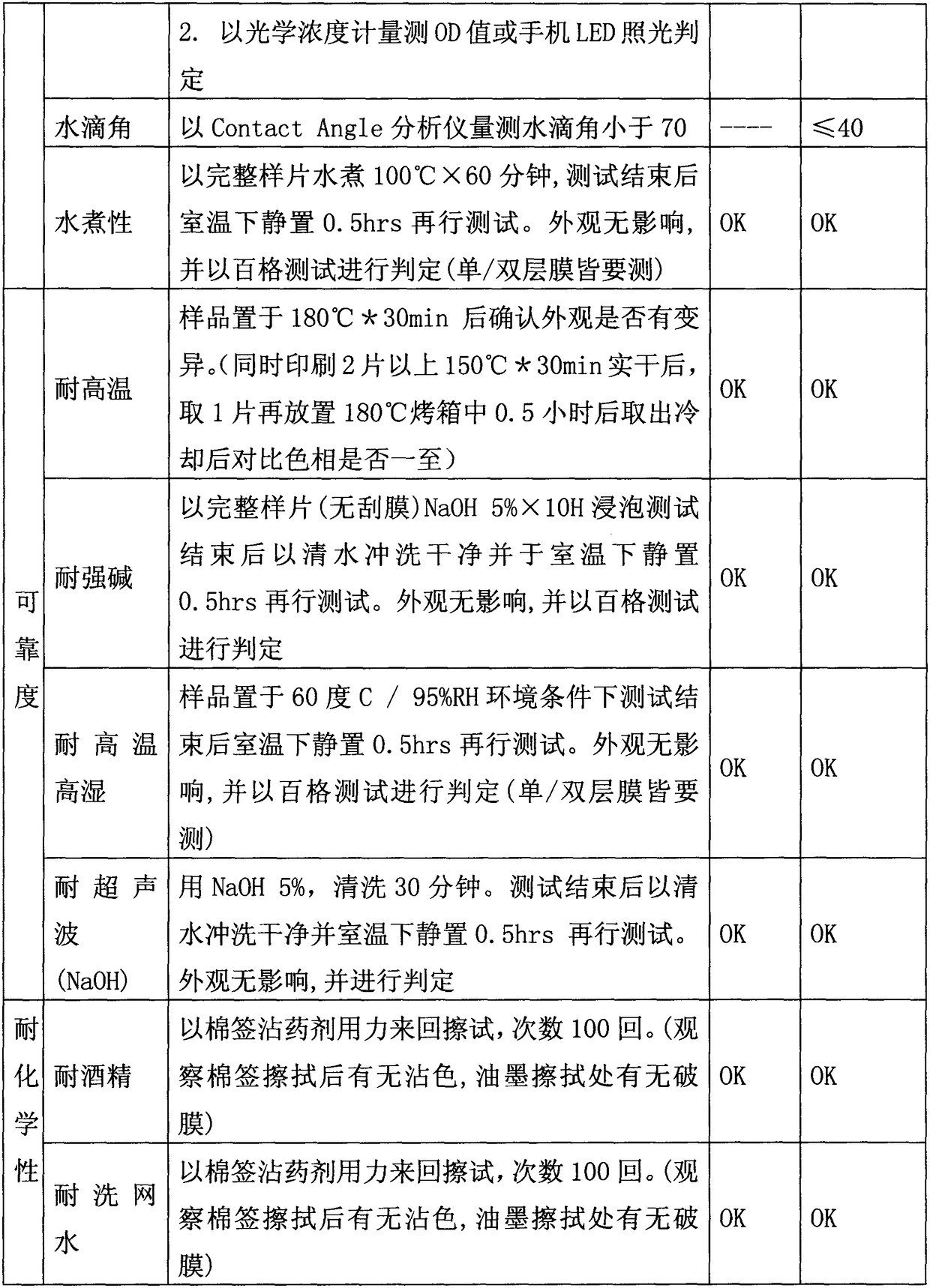

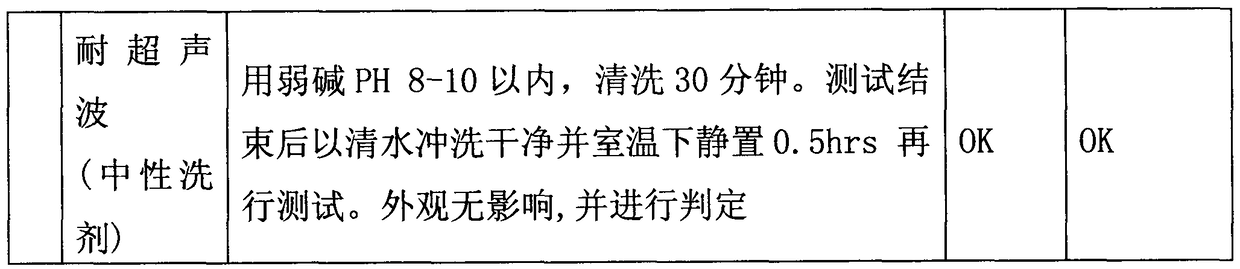

[0014] A kind of two-component modified polyester resin thermosetting ink provided by the present embodiment includes BM 607 white and BM690 high-value black, and said BM 607 white is set by the polyester resin 20- 50%, 2-10% propylene glycol methyl ether acetate, 25-35% isobolone, 40-50% titanium dioxide, and 2-5% additives; (Percentage) The mixture of 20-50% polyester resin, 2-10% propylene glycol methyl ether acetate, 25-35% isobolone, 20-30% carbon black, and 2-5% auxiliary agent are formed. The isotropic ketone is diethylene glycol monoethyl ether acetate, and the auxiliary agent is composed of a thixotropic agent, a dispersant, a leveling agent and a defoamer, and the concentration range of the thixotropic agent is <3 %, the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com