Back pressure recovery side slope drainage system and method

A drainage system and slope technology, applied in construction, infrastructure engineering, soil protection, etc., can solve the problem of low siphon start-up efficiency, achieve fast and efficient siphon start-up, wide application range, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

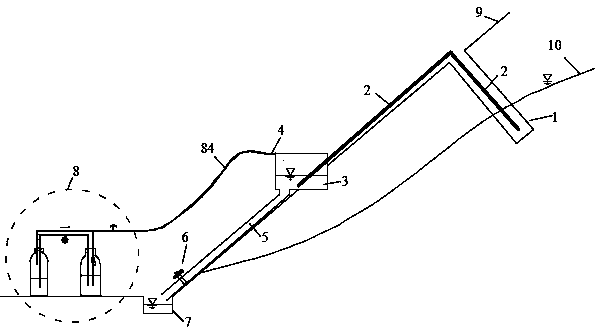

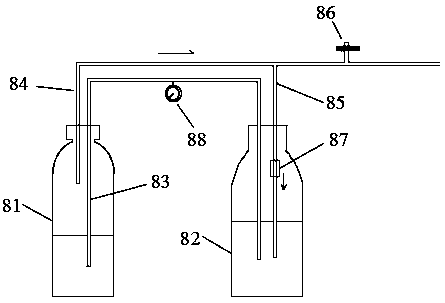

[0024] like figure 1 , figure 2 As shown, this embodiment provides a reverse pressure recovery type slope drainage system, which includes a borehole 1, a siphon 2, a water tank 3, an exhaust pipe 4, a drain pipe 5, a drain pipe valve 6, and a gas generating device 8, The gas generating device 8 includes a left gas cylinder 81, a right gas cylinder 82, a guide tube 83, a pressure gauge 88, an air guide tube 84, a branch pipe 85, an air guide tube valve 86, a one-way valve 87, and the left gas cylinder 81 contains Sodium carbonate solution is arranged, the right gas cylinder 82 is filled with acetic acid solution, the left gas cylinder 81 and the right gas cylinder 82 are connected by a flow guide tube 83, and the two ends of the flow guide tube 83 are all located below the liquid level, and the middle of the flow guide tube 83 A pressure gauge 88 is provided, the inlet end of the air guide tube 84 is placed in the left gas cylinder 81, the inlet end of the air guide tube 84 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com