Wide speed regulation range and low torque ripple suppression method of brushless direct current motor

A brush DC motor and torque ripple technology, which is applied in torque ripple control, direct torque control, motor control, etc., can solve the problem of low torque ripple suppression method with wide speed regulation range and poor commutation torque ripple suppression effect and other problems, to achieve the effect of fast torque response, increased attenuation, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

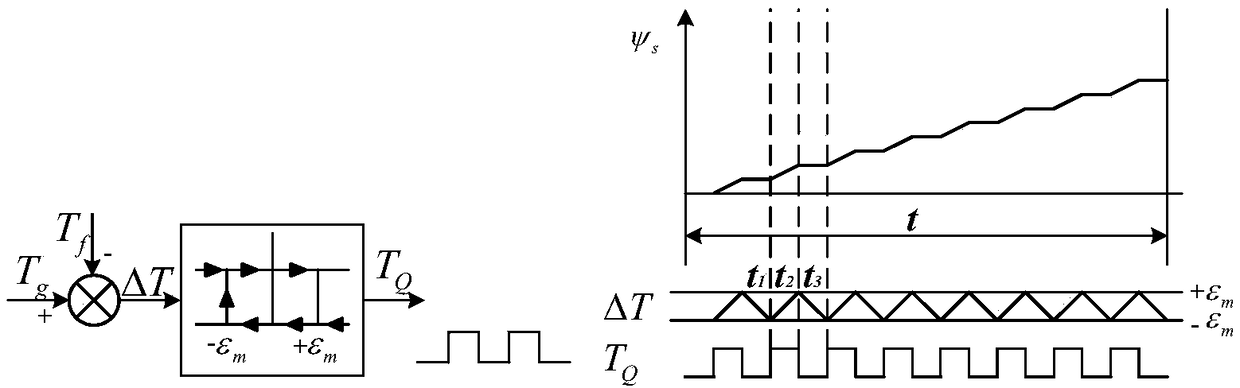

[0044] Such as figure 1 As shown, the present invention aims to solve the problem that the torque ripple suppression effect of the brushless DC motor is not ideal within a wide speed regulation range. figure 1 Is the direct torque two-point regulation process diagram. where T g is the torque given value, T f is the torque feedback value, ΔT is the torque error, T Q is the torque switch signal. The tolerance of the regulator is ±ε m , using a discrete two-point adjustment method. at time t 1 , ΔT≤—ε m ,T Q Output "1". When T Q =1, select a non-zero voltage space vector in combination with the position signal, at this time the stator flux linkage rotates forward, T f rise, ΔT increases; to time t 2 , ΔT increases to the upper limit of the tolerance + ε m , that is, ΔT≥+ε m ,T Q Output "0". When T Q =0, the zero-voltage space vector is added to the motor, and the stator flux linkage is stationary, T f Decrease, ΔT decreases.

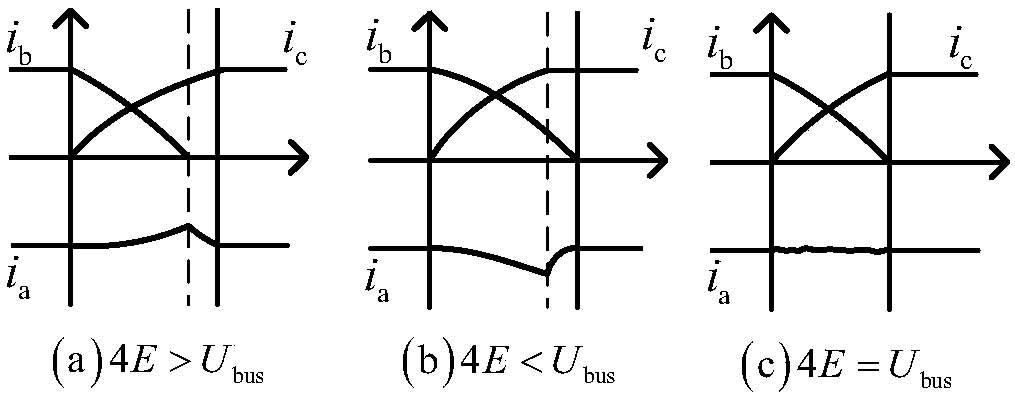

[0045] Such as figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com