A valve bottom lining cleaning device

A cleaning device and backing technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as large investment, reduced service life of valves, and failure to effectively eliminate them, so as to reduce service life and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

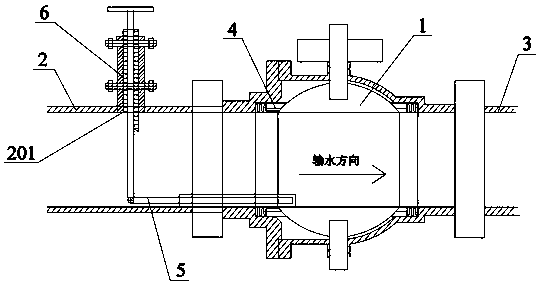

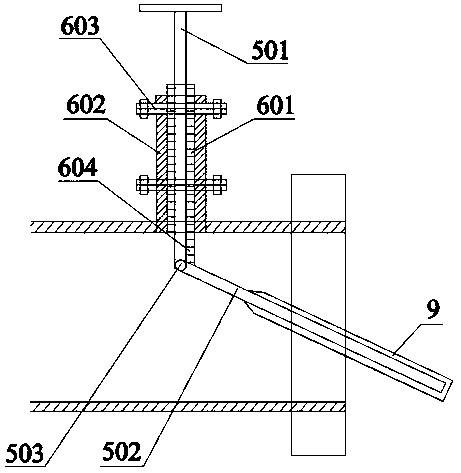

[0025] A valve lining cleaning device, the front end of the valve 1 is connected to the water inlet pipe 2, and the rear end is connected to the water outlet pipeline 3, the valve 1 is provided with a water-stop rubber lining 4, and the top of the water inlet pipe 2 is provided with a mounting hole 201, One end of the cleaning device extends into the water inlet pipe 2 through the installation hole 201, and the other end is fixed above the water inlet pipe 2;

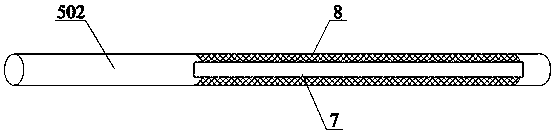

[0026] The cleaning device includes a cleaning mechanism 5 and a sealing mechanism 6, the cleaning mechanism 5 includes a connecting rod 501 and a swing rod 502, the length of the swing rod 502 is greater than the horizontal distance between the installation hole 201 and the waterproof rubber bottom lining 4 , the connecting rod 501 extends into the water inlet pipe 2 through the installation hole 201, and the lower end is connected with the swing rod 502 through a single-joint hinge 503, and the up and down movement of ...

Embodiment 2

[0035] A valve lining cleaning device, the front end of the valve 1 is connected to the water inlet pipe 2, and the rear end is connected to the water outlet pipeline 3, the valve 1 is provided with a water-stop rubber lining 4, and the top of the water inlet pipe 2 is provided with a mounting hole 201, One end of the cleaning device extends into the water inlet pipe 2 through the installation hole 201, and the other end is fixed above the water inlet pipe 2;

[0036] The cleaning device includes a cleaning mechanism 5 and a sealing mechanism 6. The cleaning mechanism 5 includes a connecting rod 501 and a swing rod 502. The connecting rod 501 is divided into two parts, the upper part is a telescopic operating rod, and the lower part is a connecting rod. The upper end of the operating rod is provided with a handle, the lower end is provided with threads, and the upper end of the connecting rod is provided with a built-in nut, which is connected with the operating rod through thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com