High pressure release type biochemical sludge conditioning method

A biochemical sludge and discharge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increased sludge treatment costs, low impact of sludge dehydration, and large limitations To achieve the effect of excellent wall breaking effect, low energy consumption and equipment cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

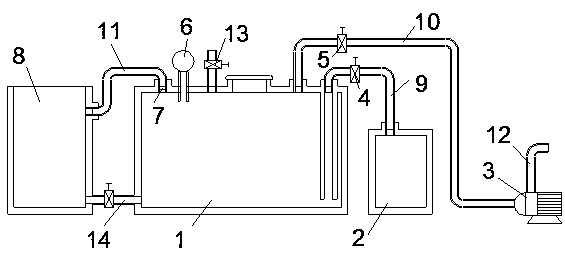

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0032] A high-pressure discharge biochemical sludge conditioning method, which is characterized in that the sludge is placed in a closed container, and then the internal pressure of the container is increased by means of pressurization. The pressure relief is completed inside, relying on the gas expansion and shock shock generated at the moment of pressure relief, the microbial cells in the sludge are broken and the sludge conditioning is realized.

[0033] In this way, relying on high-pressure discharge for sludge treatment can greatly increase the wall breaking rate of microbial cells in sludge, realize sludge conditioning, and facilitate subsequent sludge dehydration treatment. At the same time, it has the advantages of simple and convenient operation, high processing efficiency and no side effects.

[0034] Among them, the pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com