A heat-resisting and odor-free warm-mix multifunctional asphalt modifier and its preparation method and application

An asphalt modifier and a multi-functional technology are applied in the field of heat-resistant, pure-flavored, warm-mixed multi-functional asphalt modifier and its preparation field, which can solve the problem of reducing the emission of asphalt smoke, resisting heat and cooling, complex asphalt pavement construction process and cost. problems such as high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

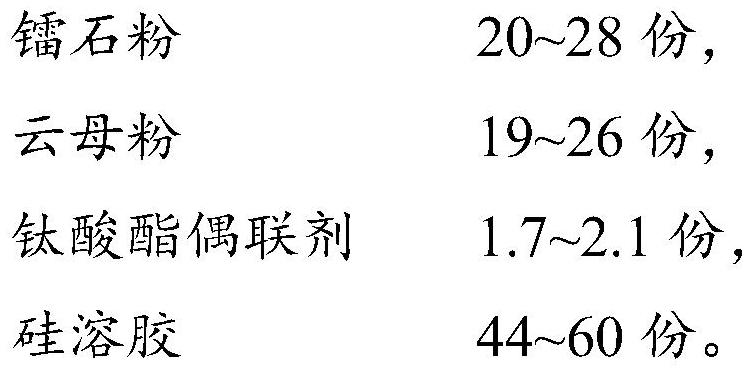

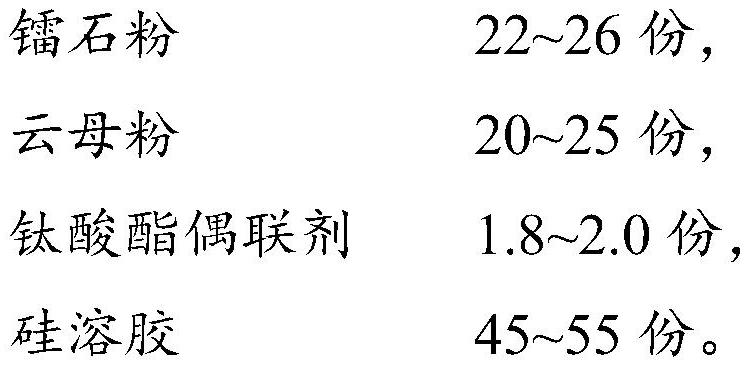

[0035] The present invention provides a preparation method of the heat-resistant, odor-free and warm-mix multifunctional asphalt modifier described in the above technology, comprising the following steps:

[0036] (1) mixing a titanate coupling agent with a silica sol to obtain a mixed sol;

[0037] (2) Mix radium stone powder, mica powder and the mixed sol obtained in the step (1) to obtain a heat-resistant, clean-tasting warm-mix multifunctional asphalt modifier.

[0038] The invention mixes the titanate coupling agent and the silica sol to obtain the mixed sol.

[0039] In the present invention, there is no special requirement on the mixing method of the titanate coupling agent and the silica sol, and a mixing method well known to those skilled in the art can be used.

[0040] In the present invention, the titanate coupling agent has very good hydrolysis stability, and the titanate coupling agent is hydrolyzed in the mixed sol.

[0041] After the mixed sol is obtained, th...

Embodiment 1

[0062] Mix the radium stone powder of 22 mass parts, the 1340 mesh muscovite powder of 21 mass parts, the chelating type titanate coupling agent 311 of 1.8 mass parts and the neutral silica sol of 55.2 mass parts, wherein the mass of silicon dioxide in the silica sol The fraction is 30%, and the heat-resisting and clean-tasting warm-mix multifunctional asphalt modifier is obtained.

Embodiment 2

[0064] Mix the radium stone powder of 21 mass parts, the 1340 mesh muscovite powder of 20 mass parts, the chelating type titanate coupling agent 311 of 1.8 mass parts and the neutral silica sol of 57.2 mass parts, wherein the mass of silicon dioxide in the silica sol The fraction is 30%, and the heat-resisting and clean-tasting warm-mix multifunctional asphalt modifier is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com